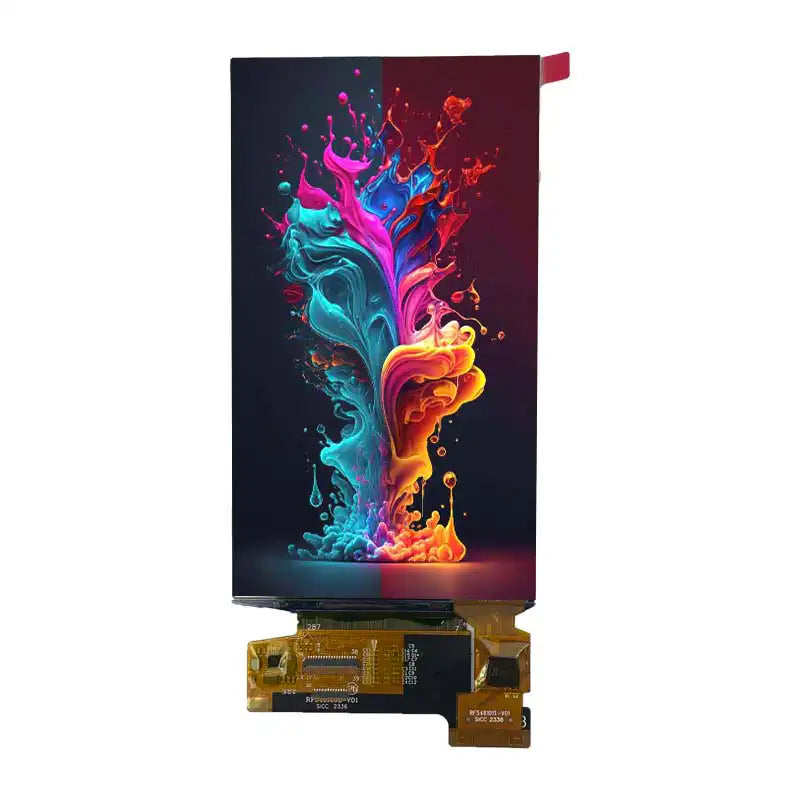

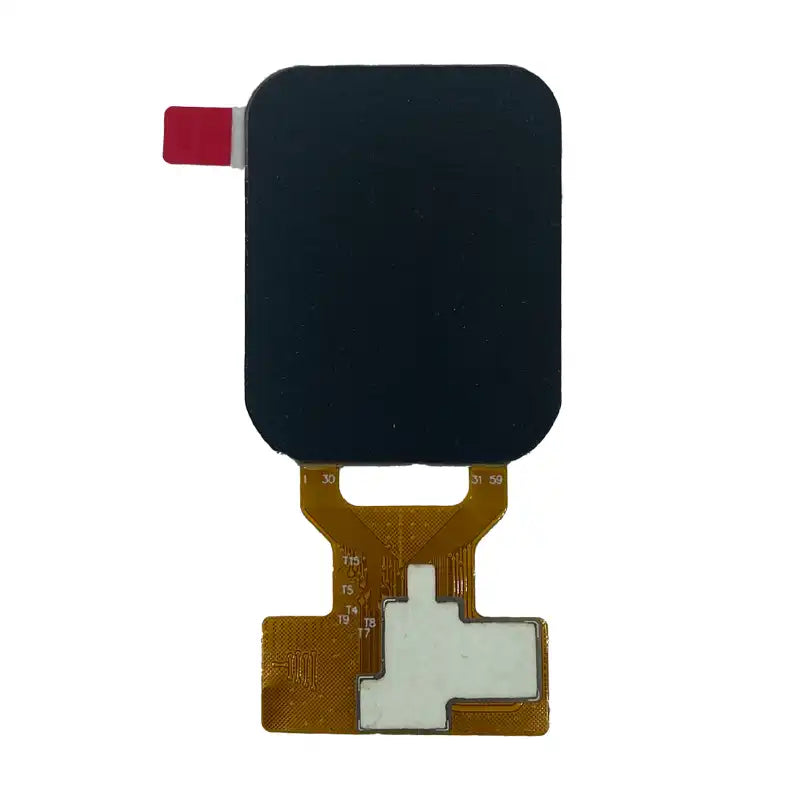

1.95 INCH AMOLED Display Module – High-Resolution Compact Display

High-Performance AMOLED Display Solutions

The 1.95-inch AMOLED module (Model: BR195103-A1) from Shenzhen Brownopto Technology Co., Ltd. is a high-resolution, compact display solution ideal for smartwatches, wearables, and portable devices. Featuring a sharp 368 × 448 resolution and vibrant AMOLED technology, this module delivers deep blacks, excellent contrast, and superior power efficiency. With a typical brightness of 600 nit and a contrast ratio of 60,000:1, it ensures excellent visibility in various lighting conditions. Designed with a QSPI interface and driven by the CH13620 IC, it offers reliable performance for modern embedded applications.

Key Features

- Display Size: 1.95 inch diagonal

- Resolution: 368 × 448 pixels

- Active Area: 30.912 × 38.1696 mm

- Module Outline: 32.672 × 41.0596 × 0.85 mm

- Technology: AMOLED (Active Matrix OLED)

- Display Colors: 16.7 million

- Interface: QSPI (Quad Serial Peripheral Interface)

- Driver IC: CH13620

- Luminance: 600 cd/m² (typ.)

- Contrast Ratio: 60,000:1 (typ.)

- Viewing Angle: 85° all directions (CR ≥10)

- NTSC Coverage: 100% (typ.)

- Lifetime (LT95): 200 hours (white pattern, 25°C)

- Operating Temperature: -20°C to +70°C

Technical Specifications

| Parameter | Value |

|---|---|

| Display Size | 1.95 inch |

| Resolution | 368 × 448 pixels |

| Active Area | 30.912 × 38.1696 mm |

| Module Outline | 32.672 × 41.0596 × 0.85 mm |

| Technology | AMOLED |

| Display Colors | 16.7 million |

| Interface | QSPI |

| Driver IC | CH13620 |

| Luminance | 600 cd/m² (typ.), 550 min |

| Contrast Ratio | 60,000:1 (typ.) |

| Viewing Angle | 85° all directions (CR≥10) |

| Uniformity | ≥85% (5-point measurement) |

| NTSC Ratio | 100% (typ.), 97% min |

| Lifetime (LT95) | 200 hours (white pattern, 25°C) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -30°C to +80°C |

| Frame Frequency | 60 Hz |

| Power Supply (VCI) | 2.7–3.6V (typ. 2.8V) |

| Logic Supply (IOVDD) | 1.65–3.6V (typ. 1.8V) |

| ELVDD Output | 3.5 V |

| ELVSS Output | -3.5 V |

| Power Consumption | 260 mW (typ., normal mode) |

| Weight | TBD |

| Compliance | RoHS |

Visual Inspection Criteria

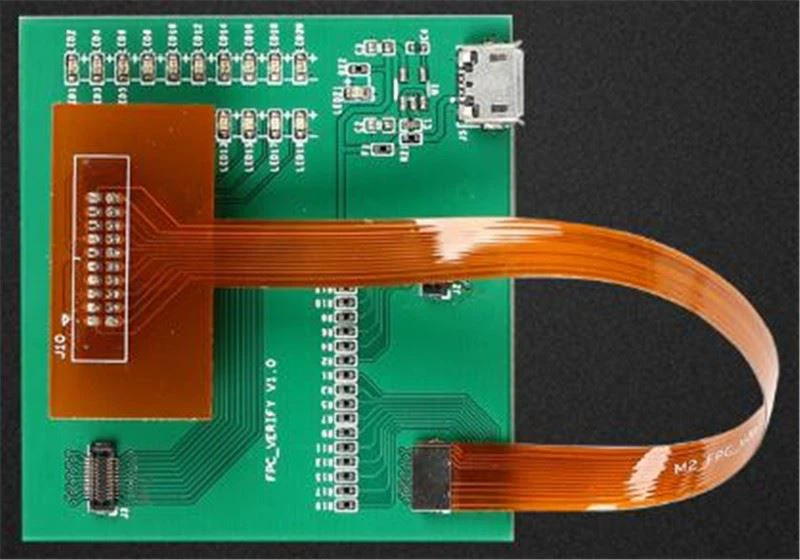

Inspection is conducted under cold white fluorescent lighting (1000±200 lux), viewing distance of 30±5 cm, and viewing angle of 45°. Defects are judged against limit samples. (Ref: Specification Section 8.4)

| No. | Inspection Item | Acceptable Criteria | Defect Type |

|---|---|---|---|

| 1 | Broken Glass | Not allowed | MA |

| 2 | Crack | Not allowed | MA |

| 3 | Edge Collapse/Corner | Y ≤ 0.15mm: ignored; 0.15 < Y ≤ 0.4mm: X ≤ 2mm, N ignored; Y > 0.4mm: not allowed; Z ≤ t | MI |

| 4 | Flange | Y ≤ 0.2mm: allowed; Y > 0.2mm: not allowed | MI |

| 5 | Pin Dirty | No control | MI |

| 6 | Pin Scratch | Scratches allowed if no broken lead or overlap | MI |

| 7 | Screen Warpage | Lifting height ≤ 0.3mm | MI |

| 8 | Color Difference/Stain | No control | MI |

| 9 | Screen Body Dirty | Front can be wiped; back not controlled | MI |

| 10 | Point Defect | D ≤ 0.1 mm: ignored; 0.1 < D ≤ 0.15 mm: N ≤ 1; D > 0.15 mm: not allowed | MI |

| 11 | Linear Defect / Foreign Matter | W ≤ 0.03mm: omitted; 0.03 < W ≤ 0.05mm: L < 3.0mm, N ≤ 2; 0.05 < W ≤ 0.07mm: L ≤ 3.0mm, N ≤ 1; W > 0.07mm or L > 3mm: not allowed | MI |

| 12 | Mixture | Not allowed | — |

| 13 | Packaging | Clean, undamaged, with clear labels and QC signature | — |

Application Scenarios

The 1.95-inch AMOLED module is ideal for applications requiring high resolution in a compact form factor:

- Wearables: Smartwatches, fitness trackers, health monitors

- Portable Devices: Handheld terminals, smart remotes

- Consumer Electronics: Audio players, IoT controllers

- Industrial HMIs: Compact control panels, diagnostic tools

Handling Precautions

- Avoid mechanical pressure or bending on the display surface.

- Use ESD-safe tools and grounding during handling and assembly.

- Clean only with IPA and lint-free cloth; avoid abrasive materials.

- Follow the recommended power-on/off sequence (refer to datasheet Section 6.3–6.4).

- Store in a dry, dark environment to prevent OLED degradation.

Resource download: specification

Need the Full Datasheet?

Contact us for the complete specification, test reports, or sample requests.

Contact SalesFeatured collection

OLED Custom Solutions

Our company offers custom-made OLED solutions, tailored to your unique display needs, ensuring high-quality, precision, and satisfaction.

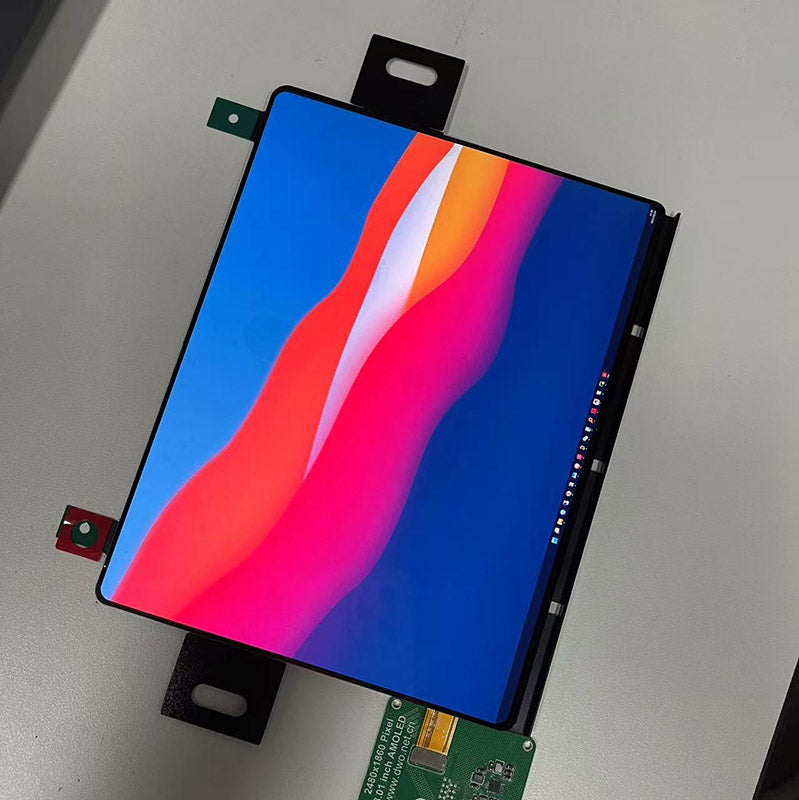

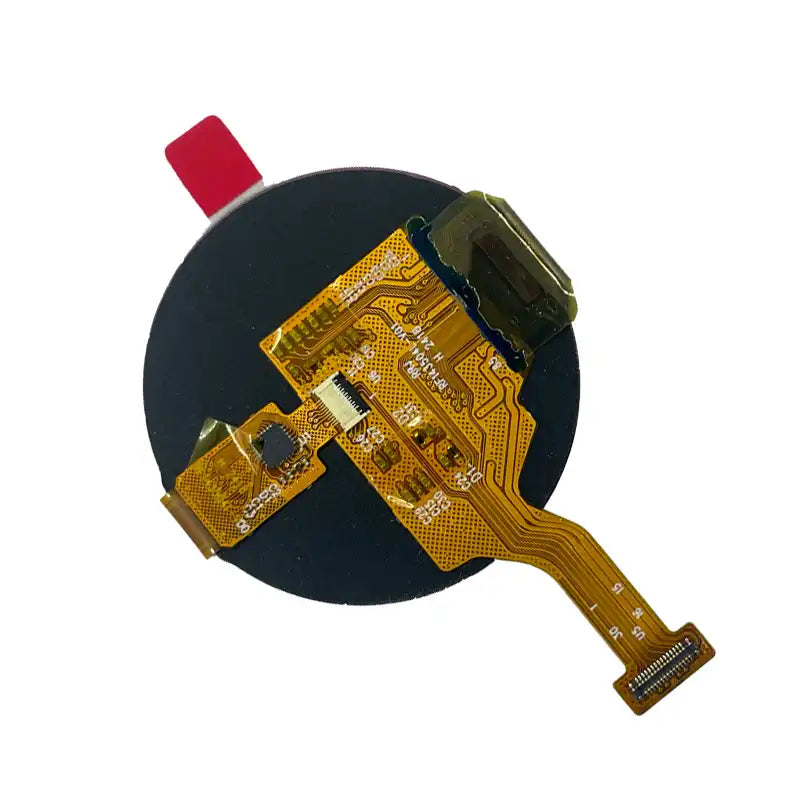

Size & Shape Customization

Tailor AMOLED dimensions and shapes (round, irregular, flexible/foldable) for wearables, phones, or industrial devices. Adjust form factors to match product design needs.

Resolution & Pixel Optimization

Offer HD to 4K+ resolutions and pixel densities for clarity. Enhance color accuracy and contrast for premium smartphones, tablets, VR/AR, and high-end displays.

Interface & Driver Integration

Configure MIPI DSI/LVDS interfaces and driver ICs for seamless hardware compatibility. Add capacitive touch support for mobile, automotive, or industrial systems.

Optical & Durability Enhancements

Add anti-glare coatings, higher brightness, and IP-rated protection. Optimize for extreme temperatures, ensuring durability in outdoor, military, or harsh environments.

FAQ

Questions about OLED Displays

1. What factors affect the cost of a custom OLED?

- Size & complexity: Larger or flexible designs increase costs.

- Resolution/pixel density: Higher specs (e.g., 4K) require advanced manufacturing.

- Material quality: High-end materials (e.g., anti-glare coatings) add to pricing.

- Minimum order quantity (MOQ): Smaller batches may incur higher per-unit costs.

2. How long does it take to produce a custom OLED?

- Lead time: Typically 4–8 weeks after design approval, depending on complexity.

- Prototyping: Sample production takes 2–3 weeks for verification.

- Mass production: Delays may occur for high-volume orders or specialized components.

3. Can I request a flexible or foldable OLED?

- Yes, but with limitations:

- Flexibility: Curved designs require specialized substrates (e.g., polyimide).

- Durability: Foldable OLEDs need reinforced layers to prevent cracking.

- Cost: Flexible/foldable options are 20–50% more expensive than rigid panels.

4.How is the reliability of custom OLEDs tested?

- Key tests:

- Lifetime testing: Accelerated aging (e.g., 85°C/85% RH for 1,000 hours).

- Mechanical stress: Flexibility/folding endurance (100,000+ cycles for foldables).

- Environmental resistance: UV exposure, humidity, and thermal shock testing.

- Performance metrics:

- Luminance retention: >90% brightness after 10,000 hours.

- Color stability: Delta E < 3 for consistent color accuracy.

- Supplier accountability: Reputable manufacturers provide test reports and warranties (e.g., 2–5 years).

5.What industries benefit most from custom OLEDs?

- Consumer electronics: Smartphones, wearables, tablets.

- Industrial/medical: Control panels, diagnostic displays.

- Automotive: Dashboard screens, infotainment systems.

- Retail/entertainment: Digital signage, AR/VR headsets.