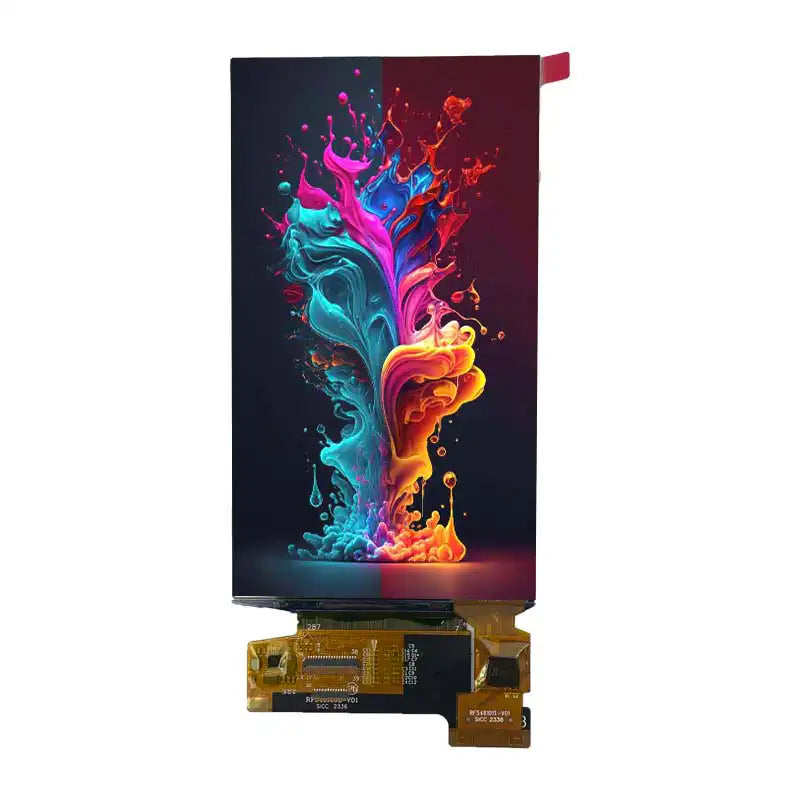

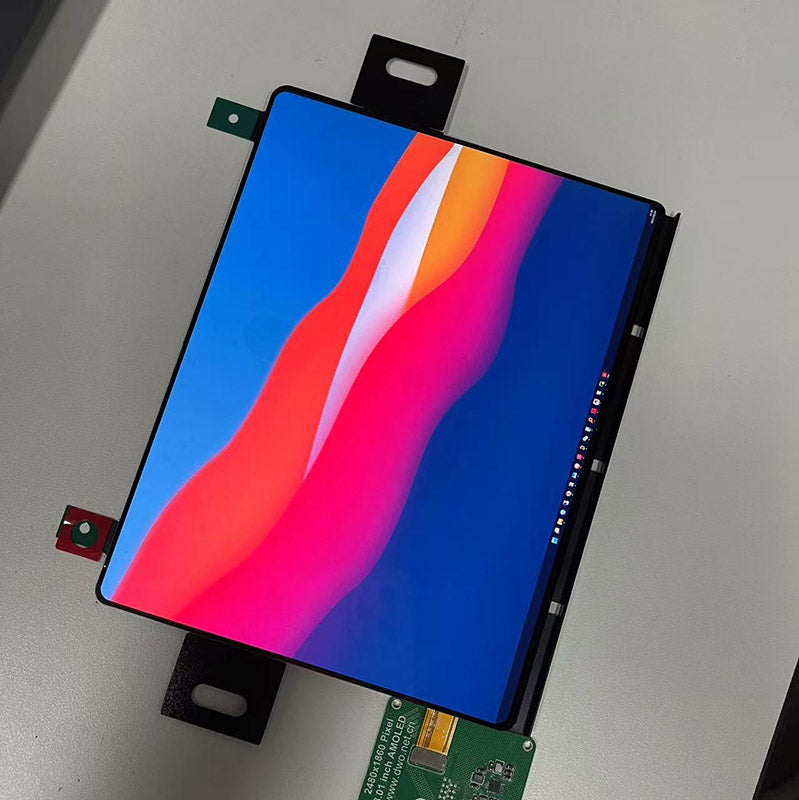

8.0 INCH WUXGA AMOLED Module 1920x1200 LTPS, LVDS & MIPI DSI

Engineered for Brilliance, Built for the Future

Introducing the 8.0" AMOLED Module

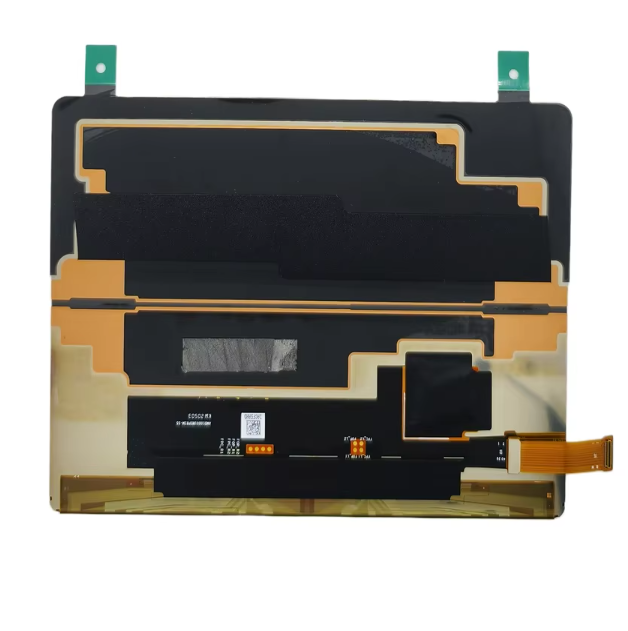

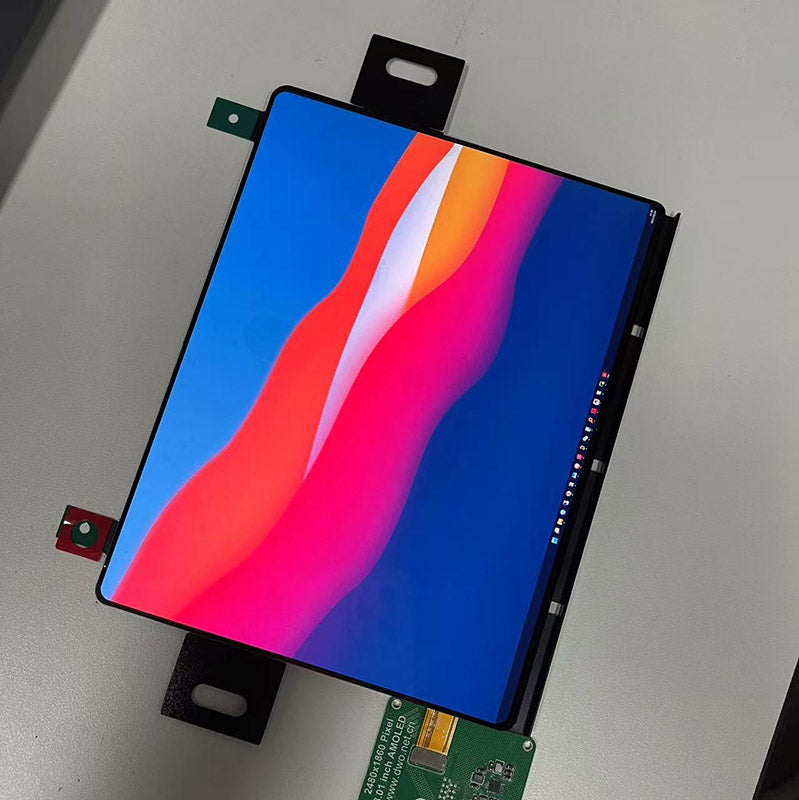

The 8.0" AMOLED module from Shenzhen Brownopto Technology Co., LTD is a high-performance, large-format display solution engineered for applications demanding vivid colors, true blacks, and exceptional energy efficiency. Leveraging advanced LTPS TFT backplane and self-emissive OLED technology, this panel delivers stunning visual clarity, wide viewing angles, and robust performance across industrial, automotive, and premium consumer applications.

Key Features:

- Screen Size: 8.0 inches (diagonal)

- Resolution: 1920 x 1200 pixels (WUXGA)

- Active Area: 172.80 mm (W) × 108.00 mm (H)

- Pixel Pitch: 90.0 µm (W) × 90.0 µm (H)

- Technology Type: AMOLED with LTPS (Low Temperature Polysilicon) TFT

- Color Depth: 16.7 million colors (24-bit RGB)

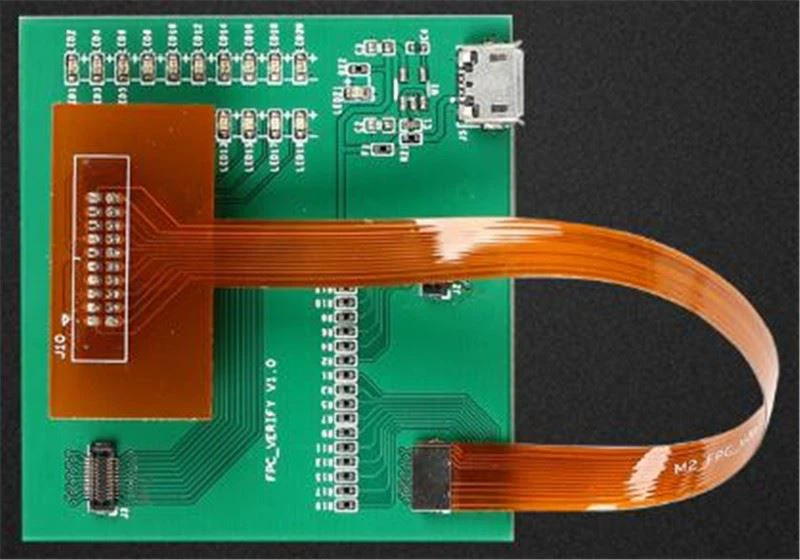

- Interface: LVDS (4-lane, 7-colors) or optional MIPI DSI (configurable)

- Polarizer Surface Treatment: HC (Hard Coating), 2H hardness, anti-reflective

- Response Time: ≤ 2 ms (typical, gray-to-gray)

- Contrast Ratio: Up to 500,000:1 (typical, self-emissive black = 0 cd/m²)

- Viewing Angle: 85°/85°/85°/85° (L/R/U/D, CR ≥ 10), nearly 180° symmetrical

- Environmental Compliance: RoHS 2.0 compliant

- Operating Temperature: -30°C to +85°C

- Storage Temperature: -40°C to +95°C

- Lifetime: 30,000 hours (typical, at 50% APL brightness)

- Frame Rate: 60 Hz (standard), up to 75 Hz (optional)

- Gamma: 2.2 (typical)

- Luminance: 800 cd/m² (typical, full white), peak 1000 cd/m² (center window)

Technical Specifications

| Parameter | Value |

|---|---|

| Screen Size | 8.0 inches |

| Display Type | AMOLED (Active Matrix Organic Light-Emitting Diode) |

| Resolution | 1920 (RGB) × 1200 pixels (WUXGA) |

| Active Area | 172.80 mm (W) × 108.00 mm (H) |

| Pixel Configuration | RGB Stripe |

| Brightness | 800 cd/m² (typical, full white), 1000 cd/m² (peak, 5% window) |

| Contrast Ratio | 500,000:1 (typical, self-emissive) |

| Viewing Angle | 85°/85°/85°/85° (L/R/U/D, CR ≥ 10) |

| Response Time | ≤ 2 ms (typical) |

| Interface | LVDS (4-lane, 7-colors) or MIPI DSI (4 lanes, 1.5Gbps/lane) |

| Operating Temperature | -30°C to +85°C |

| Storage Temperature | -40°C to +95°C |

| Power Supply | VDD: 2.7V–3.6V, VPOS: 2.8V–4.6V, VNEG: -0.6V to -5V |

| Lifetime | 30,000 hours (typical, 50% average picture level) |

| Frame Rate | 60 Hz (standard), 75 Hz (optional) |

| Surface | Hard Coating (2H), Anti-Reflective (AR) treatment |

Detailed Application Scenarios

The 8.0" AMOLED module is ideal for high-end applications requiring large, high-resolution displays with excellent contrast and reliability. Its superior image quality and wide temperature range make it suitable for mission-critical environments:

- Industrial HMIs: Advanced control panels, automation dashboards, and SCADA systems with daylight-readable clarity.

- Automotive Infotainment: Center consoles, digital cockpits, and rear-seat entertainment with cinematic visuals.

- Medical Imaging: Diagnostic monitors, surgical displays, and portable ultrasound with accurate color and contrast.

- Professional Tablets: Rugged tablets for field service, logistics, and defense with immersive UX.

- Digital Cockpits (Avionics/Marine): Primary flight displays and navigation systems with fast response and wide viewing.

- High-End Consumer Devices: Premium media players, smart home control hubs, and gaming handhelds.

- Security & Surveillance: Multi-channel NVR monitors and command center displays.

- Digital Signage: Indoor kiosks, retail displays, and information boards with vibrant visuals.

Handling Precautions

To ensure long-lasting performance and reliability, follow these handling precautions:

- Avoid mechanical shocks—do not drop or press on the screen surface.

- Use soft, lint-free, dry cloths for cleaning; avoid abrasive materials or solvents except ethyl/isopropyl alcohol.

- Do not disassemble or modify the module—internal components are sensitive and not user-serviceable.

- Prevent ESD damage—always use anti-static wrist straps, mats, and grounded tools during handling.

- Store in a cool, dry, dust-free environment between -20°C and +40°C if long-term.

- Avoid displaying static images for prolonged periods to minimize image retention risk.

- Power on/off according to recommended sequences to protect OLED materials.

Resource download: specification

Ready to Integrate?

Contact us for samples, datasheets, or custom design support.

Request a Quote

Featured collection

OLED Custom Solutions

Our company offers custom-made OLED solutions, tailored to your unique display needs, ensuring high-quality, precision, and satisfaction.

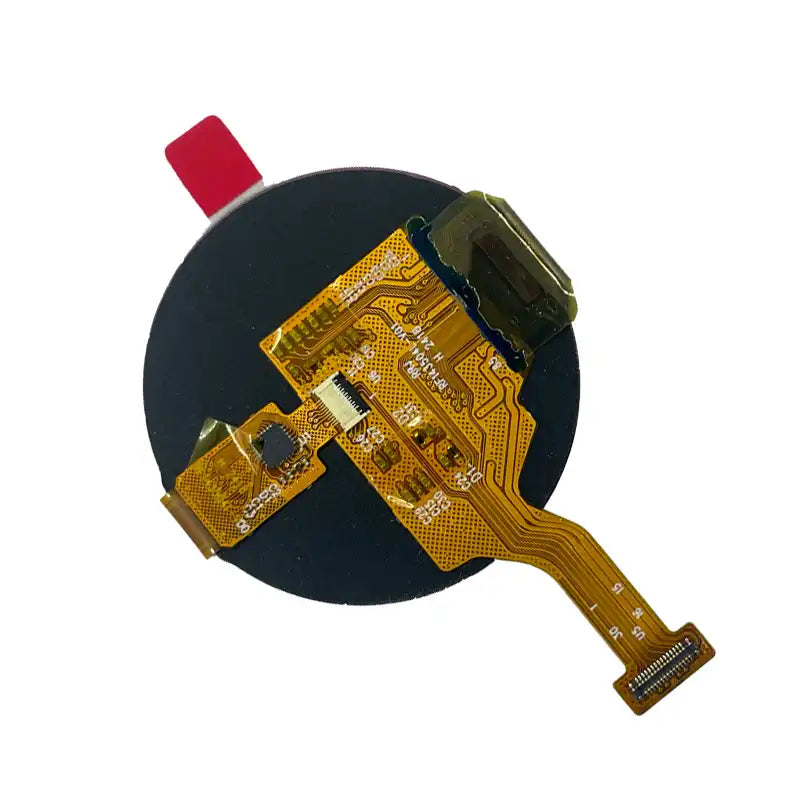

Size & Shape Customization

Tailor AMOLED dimensions and shapes (round, irregular, flexible/foldable) for wearables, phones, or industrial devices. Adjust form factors to match product design needs.

Resolution & Pixel Optimization

Offer HD to 4K+ resolutions and pixel densities for clarity. Enhance color accuracy and contrast for premium smartphones, tablets, VR/AR, and high-end displays.

Interface & Driver Integration

Configure MIPI DSI/LVDS interfaces and driver ICs for seamless hardware compatibility. Add capacitive touch support for mobile, automotive, or industrial systems.

Optical & Durability Enhancements

Add anti-glare coatings, higher brightness, and IP-rated protection. Optimize for extreme temperatures, ensuring durability in outdoor, military, or harsh environments.

FAQ

Questions about OLED Displays

1. What factors affect the cost of a custom OLED?

- Size & complexity: Larger or flexible designs increase costs.

- Resolution/pixel density: Higher specs (e.g., 4K) require advanced manufacturing.

- Material quality: High-end materials (e.g., anti-glare coatings) add to pricing.

- Minimum order quantity (MOQ): Smaller batches may incur higher per-unit costs.

2. How long does it take to produce a custom OLED?

- Lead time: Typically 4–8 weeks after design approval, depending on complexity.

- Prototyping: Sample production takes 2–3 weeks for verification.

- Mass production: Delays may occur for high-volume orders or specialized components.

3. Can I request a flexible or foldable OLED?

- Yes, but with limitations:

- Flexibility: Curved designs require specialized substrates (e.g., polyimide).

- Durability: Foldable OLEDs need reinforced layers to prevent cracking.

- Cost: Flexible/foldable options are 20–50% more expensive than rigid panels.

4.How is the reliability of custom OLEDs tested?

- Key tests:

- Lifetime testing: Accelerated aging (e.g., 85°C/85% RH for 1,000 hours).

- Mechanical stress: Flexibility/folding endurance (100,000+ cycles for foldables).

- Environmental resistance: UV exposure, humidity, and thermal shock testing.

- Performance metrics:

- Luminance retention: >90% brightness after 10,000 hours.

- Color stability: Delta E < 3 for consistent color accuracy.

- Supplier accountability: Reputable manufacturers provide test reports and warranties (e.g., 2–5 years).

5.What industries benefit most from custom OLEDs?

- Consumer electronics: Smartphones, wearables, tablets.

- Industrial/medical: Control panels, diagnostic displays.

- Automotive: Dashboard screens, infotainment systems.

- Retail/entertainment: Digital signage, AR/VR headsets.