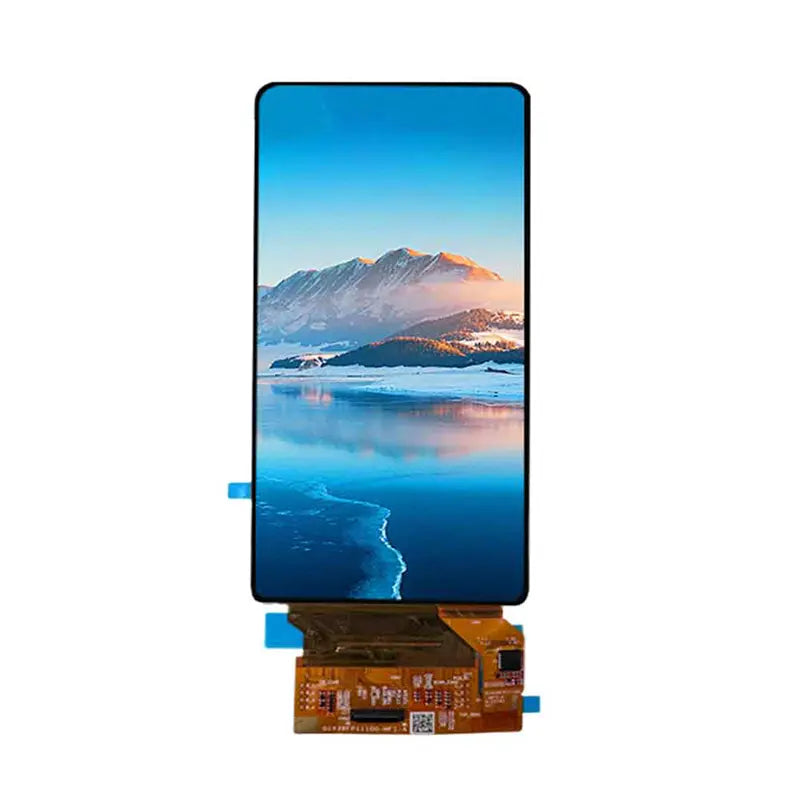

6.01 INCH AMOLED Display 1080x2160 SPI/MIPI DSI, LTPS TFT – Brown Opto

Engineered for Brilliance, Built for the Future

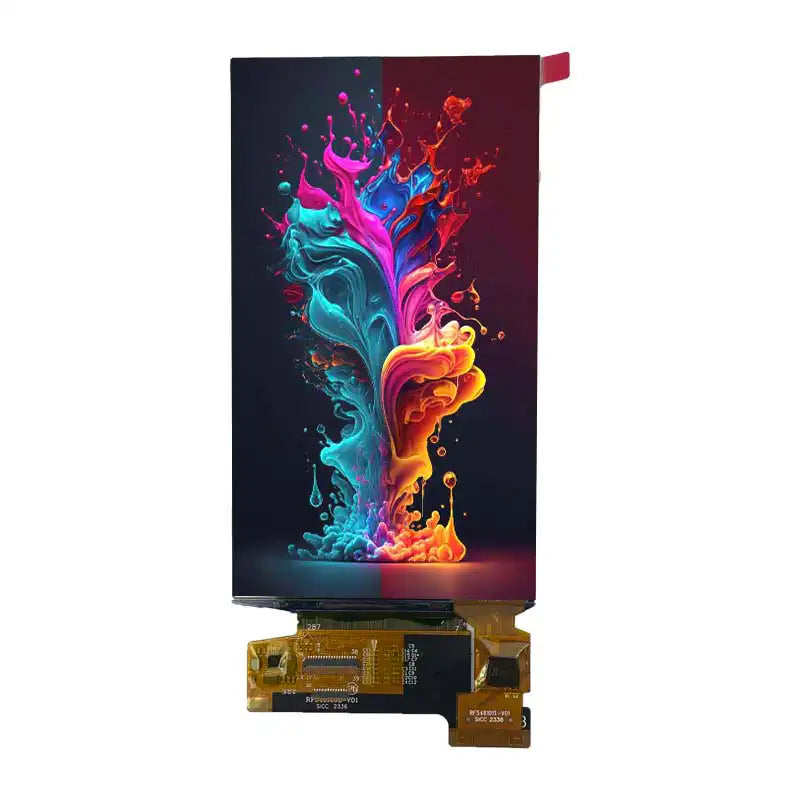

Introducing the 6.01" AMOLED Module

The 6.01" AMOLED Module from Shenzhen Brownopto Technology Co., Ltd. represents the pinnacle of display technology, offering vibrant colors, deep blacks, and unparalleled contrast ratios. This module is ideal for applications ranging from smartphones to high-end wearables, medical devices, and industrial HMIs.

Key Features

- True Blacks & Infinite Contrast – Each pixel emits its own light, allowing for perfect black levels and infinite contrast ratios.

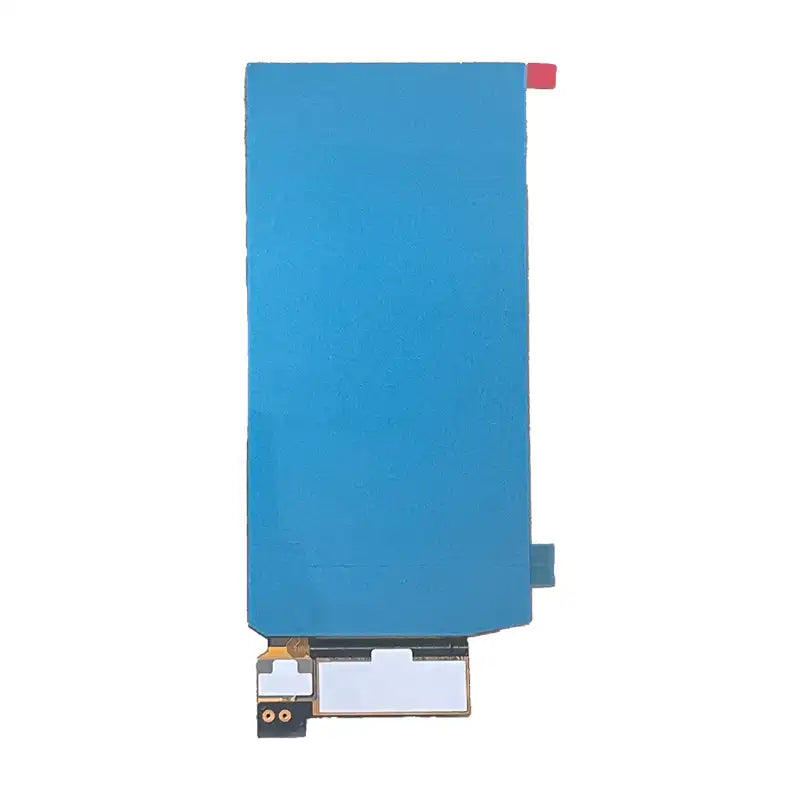

- Ultra-Thin and Lightweight – The module measures just 70.066(W)x142.297(H)x0.773(D) mm, making it suitable for compact designs.

- Wide Viewing Angles (up to 178°) – Consistent color and brightness from any angle.

- Fast Response Time (<0.1ms) – Eliminates motion blur, ideal for gaming and video.

- Energy Efficient – Uses less power when displaying dark content, extending battery life.

- Flexible & Rigid Options – Available on glass or plastic substrates.

Technical Specifications

| Feature | Spec | Remark |

|---|---|---|

| Screen Size | 6.01 inch | |

| Display Mode | AMOLED | |

| Resolution | 1080(W)×2160(H) dots | |

| Active Area | 68.256(W)×136.512(H) mm | |

| Pixel Pitch | 63.2(W)×63.2(H) um | |

| Technology Type | LTPS | |

| Color Depth | 16.7M | |

| Interface | MIPI 4LANE | |

| Surface Treatment | Hard Coating | |

| Module Outline Dimension | 70.066(W)x142.297(H)x0.773(D) mm | |

| Weight | TBD | |

| Driver IC | CH13721C | |

| Touch IC | CST148 |

Detailed Application Scenarios

The 6.01" AMOLED Module from Shenzhen Brownopto Technology Co., Ltd. is designed for a wide range of applications across multiple industries due to its advanced features and superior performance. Below are some detailed application scenarios:

- Smartphones & Phablets – With its high resolution and vivid colors, this module is perfect for flagship smartphones and phablets that require stunning visual experiences.

- Wearable Devices – Compact size and lightweight design make it ideal for smartwatches and fitness trackers where space is limited but clarity and visibility are crucial.

- Medical Devices – High contrast ratio and fast response time are essential for portable medical monitors and diagnostic tools, ensuring accurate readings and patient monitoring.

- Automotive Displays – The module's durability and wide viewing angles make it suitable for automotive infotainment systems, digital instrument clusters, and heads-up displays (HUD).

- Industrial Control Panels – Ruggedized versions of this module can be used in harsh environments such as factory automation and control systems, providing reliable operation under extreme conditions.

- Augmented Reality (AR) & Virtual Reality (VR) – Its high refresh rate and low latency make it an excellent choice for AR/VR headsets, delivering immersive experiences without motion blur.

- Point-of-Sale (POS) Terminals – High-brightness options ensure readability in direct sunlight, making it suitable for outdoor POS terminals and kiosks.

- Drone Displays – Fast response times and high contrast ratios are critical for FPV goggles and drone controllers, providing pilots with clear and responsive visuals.

- Smart Home Devices – Integrated into smart home hubs, security cameras, and voice assistants, this module provides users with clear and interactive interfaces.

- Portable Gaming Devices – High-refresh-rate versions of this module offer smooth gameplay and vibrant colors, enhancing the gaming experience on handheld consoles.

- Educational Tools – Interactive learning devices benefit from the module's high resolution and touch integration, making them ideal for educational tablets and e-readers.

- Security Systems – Used in doorbell cameras and surveillance systems, the module ensures clear video feed and easy access to settings and alerts.

- Consumer Electronics – From wireless earbuds charging cases to portable media players, this module enhances user interaction and experience with its vibrant display capabilities.

Environmental and Reliability Testing

The 6.01" AMOLED Module has undergone rigorous environmental and reliability testing to ensure long-term performance and durability. These tests include:

- High Temperature Operation (+70°C, 120hrs)

- Low Temperature Operation (-20°C, 120hrs)

- High Temperature Storage (+80°C, 120hrs)

- Low Temperature Storage (-30°C, 120hrs)

- High Temperature & High Humidity Operation (60°C, 90% RH, 120hrs)

- High Temperature & High Humidity Storage (60°C, 90% RH, 120hrs)

- Thermal Shock (-30°C to +70°C, 30 cycles)

- Electrostatic Discharge (Air: ±8KV, Contact: ±4KV)

Customization & Support

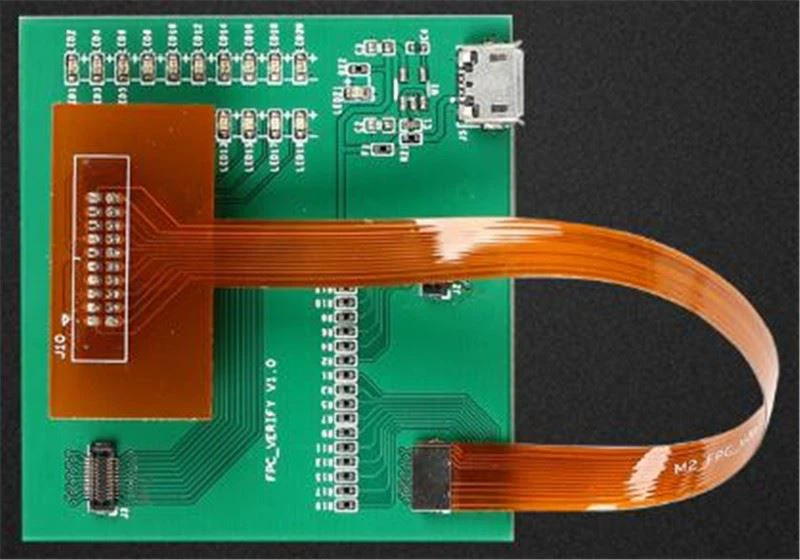

We offer full customization services for OEMs and system integrators, including:

- Custom screen shape and bezel design

- Touch panel integration (single/dual layer)

- FPC tail customization

- Driver IC and firmware optimization

- Prototyping and volume production support

Resource download: specification

Featured collection

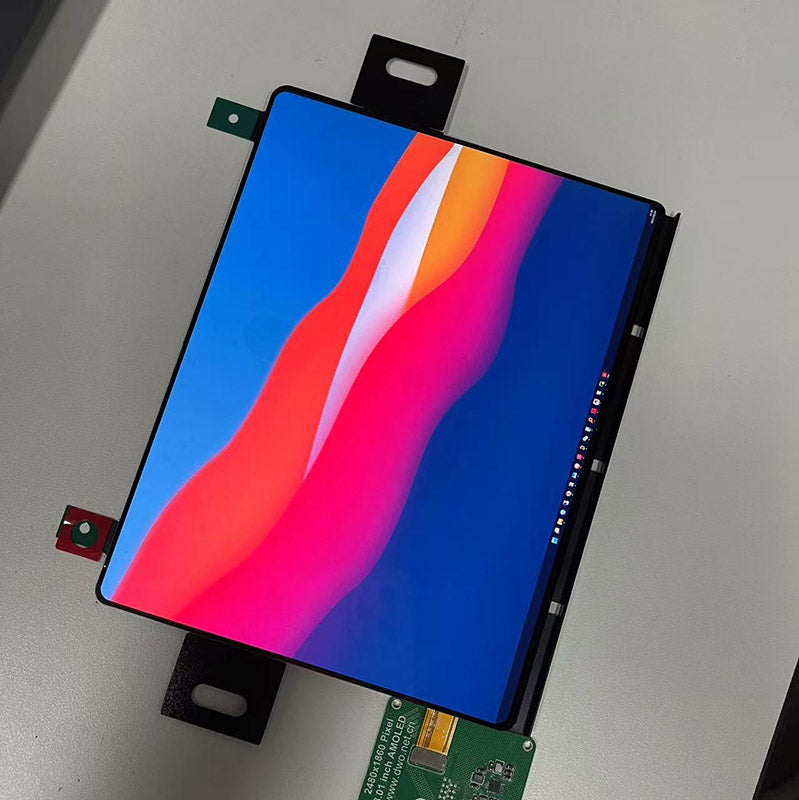

OLED Custom Solutions

Our company offers custom-made OLED solutions, tailored to your unique display needs, ensuring high-quality, precision, and satisfaction.

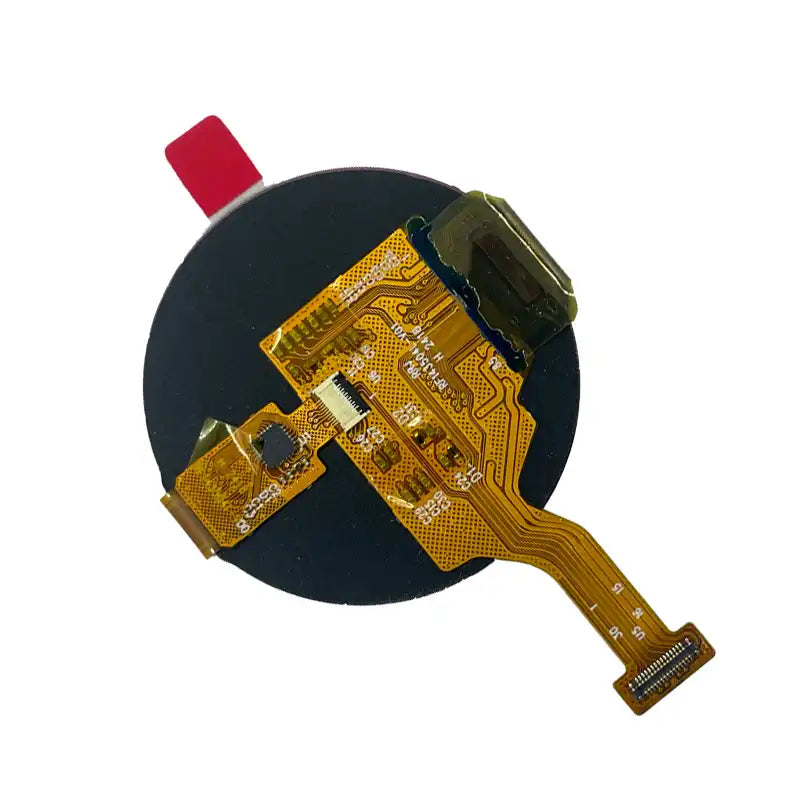

Size & Shape Customization

Tailor AMOLED dimensions and shapes (round, irregular, flexible/foldable) for wearables, phones, or industrial devices. Adjust form factors to match product design needs.

Resolution & Pixel Optimization

Offer HD to 4K+ resolutions and pixel densities for clarity. Enhance color accuracy and contrast for premium smartphones, tablets, VR/AR, and high-end displays.

Interface & Driver Integration

Configure MIPI DSI/LVDS interfaces and driver ICs for seamless hardware compatibility. Add capacitive touch support for mobile, automotive, or industrial systems.

Optical & Durability Enhancements

Add anti-glare coatings, higher brightness, and IP-rated protection. Optimize for extreme temperatures, ensuring durability in outdoor, military, or harsh environments.

FAQ

Questions about OLED Displays

1. What factors affect the cost of a custom OLED?

- Size & complexity: Larger or flexible designs increase costs.

- Resolution/pixel density: Higher specs (e.g., 4K) require advanced manufacturing.

- Material quality: High-end materials (e.g., anti-glare coatings) add to pricing.

- Minimum order quantity (MOQ): Smaller batches may incur higher per-unit costs.

2. How long does it take to produce a custom OLED?

- Lead time: Typically 4–8 weeks after design approval, depending on complexity.

- Prototyping: Sample production takes 2–3 weeks for verification.

- Mass production: Delays may occur for high-volume orders or specialized components.

3. Can I request a flexible or foldable OLED?

- Yes, but with limitations:

- Flexibility: Curved designs require specialized substrates (e.g., polyimide).

- Durability: Foldable OLEDs need reinforced layers to prevent cracking.

- Cost: Flexible/foldable options are 20–50% more expensive than rigid panels.

4.How is the reliability of custom OLEDs tested?

- Key tests:

- Lifetime testing: Accelerated aging (e.g., 85°C/85% RH for 1,000 hours).

- Mechanical stress: Flexibility/folding endurance (100,000+ cycles for foldables).

- Environmental resistance: UV exposure, humidity, and thermal shock testing.

- Performance metrics:

- Luminance retention: >90% brightness after 10,000 hours.

- Color stability: Delta E < 3 for consistent color accuracy.

- Supplier accountability: Reputable manufacturers provide test reports and warranties (e.g., 2–5 years).

5.What industries benefit most from custom OLEDs?

- Consumer electronics: Smartphones, wearables, tablets.

- Industrial/medical: Control panels, diagnostic displays.

- Automotive: Dashboard screens, infotainment systems.

- Retail/entertainment: Digital signage, AR/VR headsets.