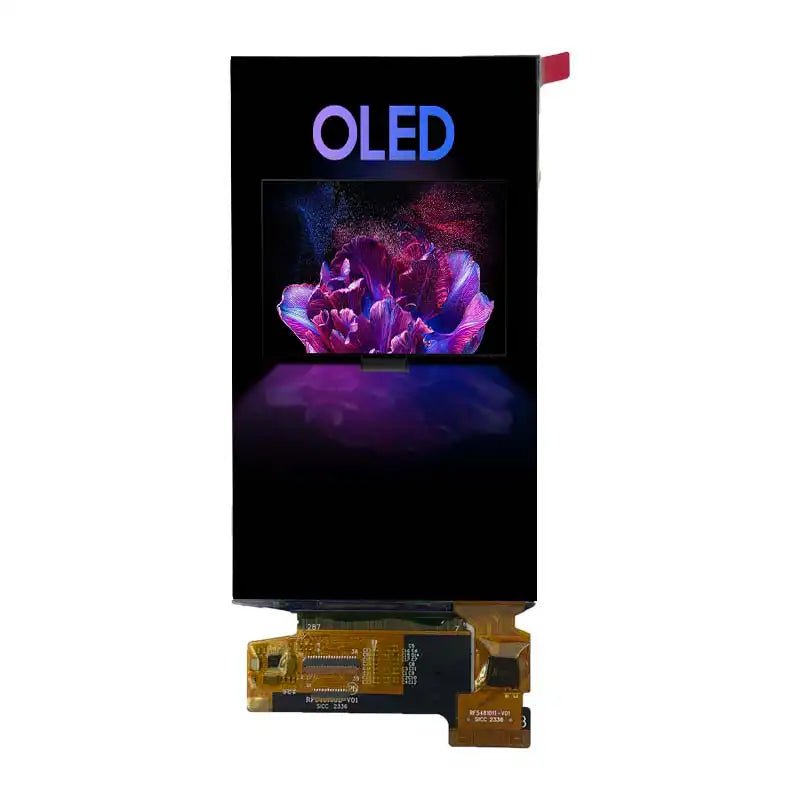

5.48 INCH AMOLED Module 1080x1920 LTPS, MIPI 4-Lane

Engineered for Brilliance, Built for the Future

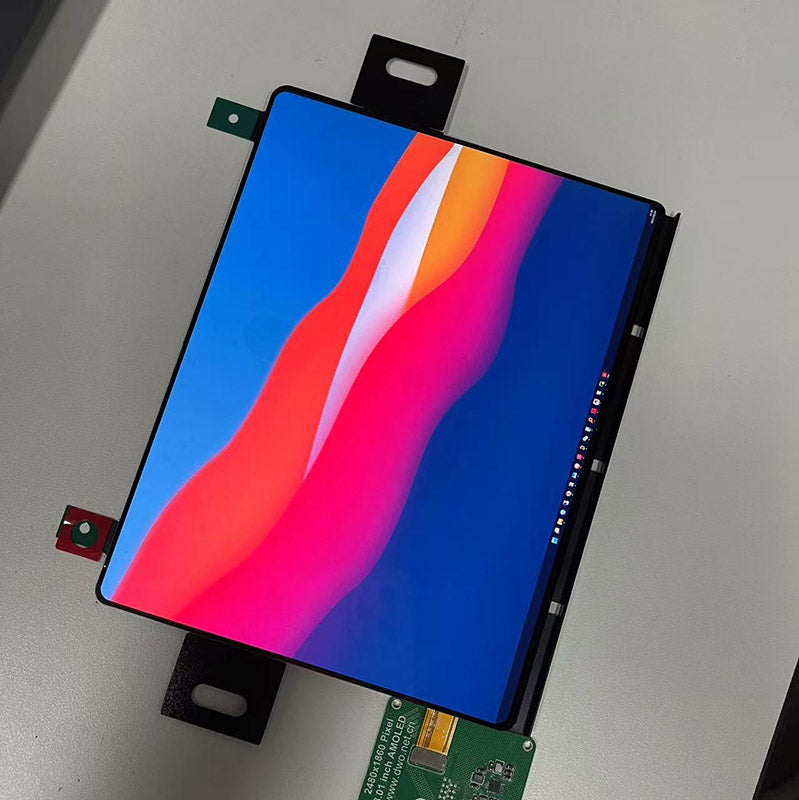

Introducing the 5.48" AMOLED Module

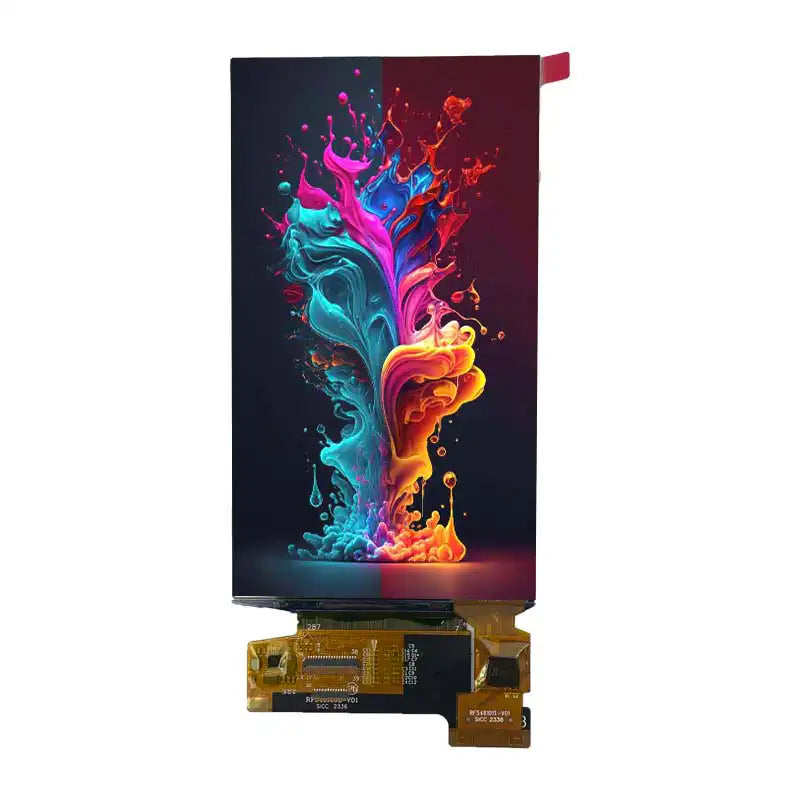

The 5.48" AMOLED module from Shenzhen Brownopto Technology Co., LTD is a high-performance display solution designed for applications requiring vibrant colors, deep blacks, and energy efficiency. With its advanced LTPS technology and robust environmental testing, this panel offers superior performance in various scenarios.

Key Features:

- Screen Size: 5.48 inches

- Resolution: 1080(W)×1920(H)

- Active Area: 68.26(W)x121.34(H) mm

- Technology Type: LTPS (Low Temperature Polysilicon)

- Color Depth: 16.7M Colors

- Interface: MIPI 4LANE

- Surface Treatment: Hard Coating

- Driver IC: CH13721

- Touch IC: CST148

- Response Time: Rise time (TON): 10% to 90%, Fall time (TOFF): 90% to 10%

- Luminance Uniformity: Calculated using active area divided into 9 measuring areas

- Environmental/Reliability Testing: High/Low Temperature Operation and Storage, High Humidity, Thermal Shock, Electrostatic Discharge

Technical Specifications

| Parameter | Value |

|---|---|

| Size Range | 5.48" |

| Resolution | 1080(W)×1920(H) |

| Brightness | Adjustable, up to 1000 cd/m² |

| Contrast Ratio | 1,000,000:1 |

| Operating Temp. | -30°C to +70°C |

| Storage Temp. | 0°C to +40°C |

| Interface | MIPI DSI |

Detailed Application Scenarios

The 5.48" AMOLED module is ideal for a variety of applications due to its compact size, high resolution, and excellent visual performance. Here are some real-world use cases:

- Smartphones: High-resolution displays with vivid colors and deep blacks for flagship devices.

- Portable Medical Devices: Clear and accurate display for patient monitoring systems and diagnostic tools.

- Industrial HMIs: Ruggedized panels for factory automation and control systems with wide temperature tolerance.

- Automotive Displays: Dashboard screens and infotainment systems offering sharp visuals under varying lighting conditions.

- Wearable Devices: Smartwatches and fitness trackers with always-on display capability and high brightness.

- Security Systems: Doorbell cameras and handheld NVRs with instant playback and settings adjustment.

- Educational Tools: Interactive learning devices with touch integration for children’s tablets and e-readers.

- Consumer Electronics: Smart home hubs, audio players, and cameras with modern user interfaces.

Handling Precautions

To ensure long-lasting performance and reliability, follow these handling precautions:

- Avoid mechanical shocks by dropping or pressing too hard on the screen.

- Use soft, dry cloths for cleaning and avoid harsh solvents except ethyl alcohol.

- Do not attempt to disassemble the AMOLED module.

- Handle with care to prevent static electricity damage.

- Ensure proper grounding during assembly and maintenance.

Resource download: specification

Ready to Integrate?

Contact us for samples, datasheets, or custom design support.

Request a Quote

Featured collection

OLED Custom Solutions

Our company offers custom-made OLED solutions, tailored to your unique display needs, ensuring high-quality, precision, and satisfaction.

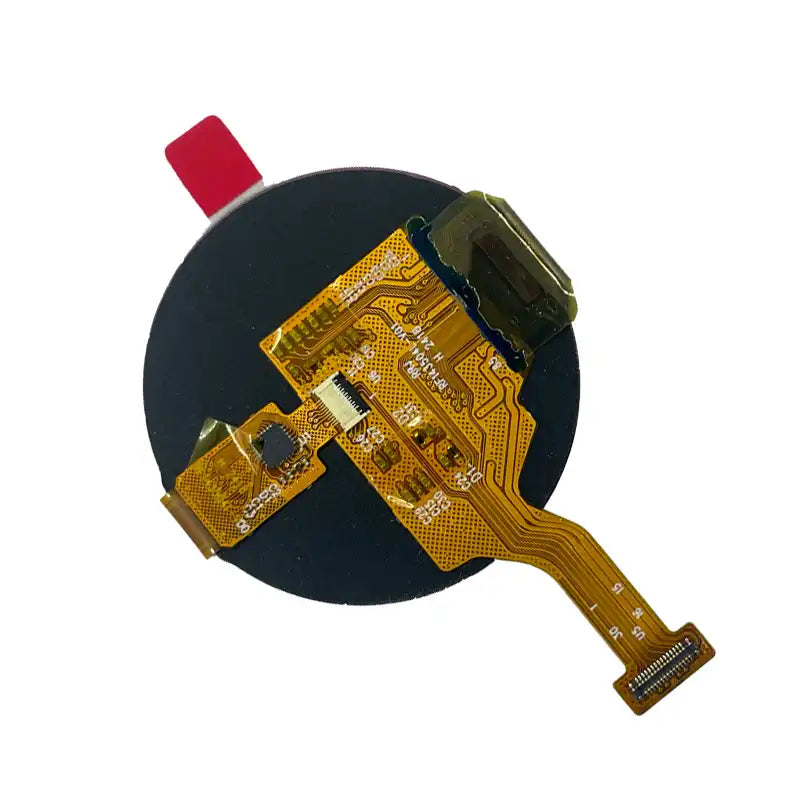

Size & Shape Customization

Tailor AMOLED dimensions and shapes (round, irregular, flexible/foldable) for wearables, phones, or industrial devices. Adjust form factors to match product design needs.

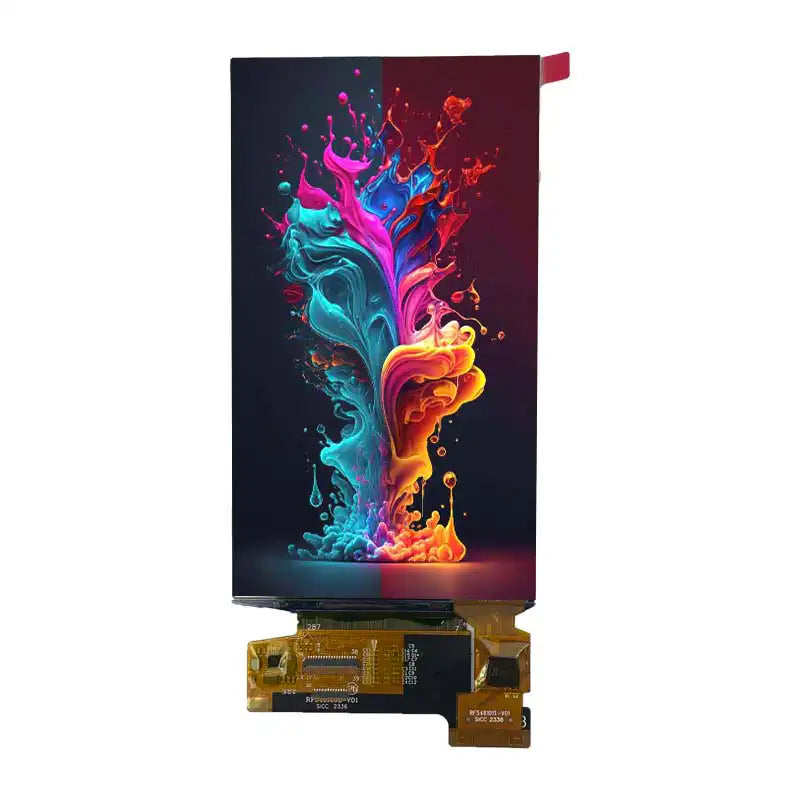

Resolution & Pixel Optimization

Offer HD to 4K+ resolutions and pixel densities for clarity. Enhance color accuracy and contrast for premium smartphones, tablets, VR/AR, and high-end displays.

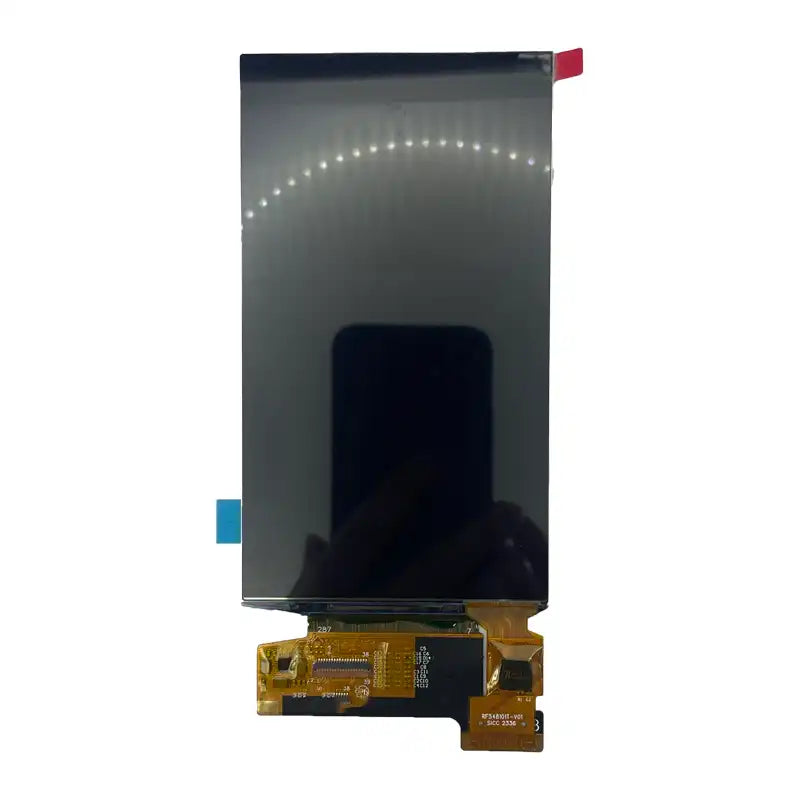

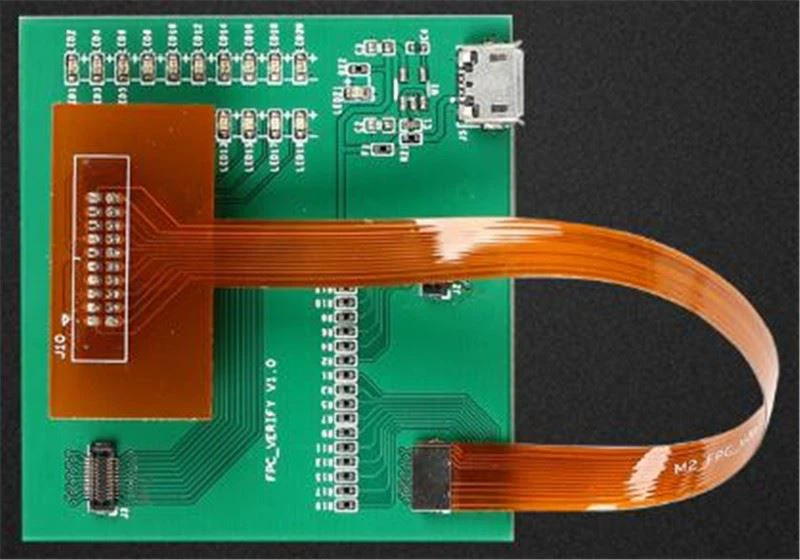

Interface & Driver Integration

Configure MIPI DSI/LVDS interfaces and driver ICs for seamless hardware compatibility. Add capacitive touch support for mobile, automotive, or industrial systems.

Optical & Durability Enhancements

Add anti-glare coatings, higher brightness, and IP-rated protection. Optimize for extreme temperatures, ensuring durability in outdoor, military, or harsh environments.

FAQ

Questions about OLED Displays

1. What factors affect the cost of a custom OLED?

- Size & complexity: Larger or flexible designs increase costs.

- Resolution/pixel density: Higher specs (e.g., 4K) require advanced manufacturing.

- Material quality: High-end materials (e.g., anti-glare coatings) add to pricing.

- Minimum order quantity (MOQ): Smaller batches may incur higher per-unit costs.

2. How long does it take to produce a custom OLED?

- Lead time: Typically 4–8 weeks after design approval, depending on complexity.

- Prototyping: Sample production takes 2–3 weeks for verification.

- Mass production: Delays may occur for high-volume orders or specialized components.

3. Can I request a flexible or foldable OLED?

- Yes, but with limitations:

- Flexibility: Curved designs require specialized substrates (e.g., polyimide).

- Durability: Foldable OLEDs need reinforced layers to prevent cracking.

- Cost: Flexible/foldable options are 20–50% more expensive than rigid panels.

4.How is the reliability of custom OLEDs tested?

- Key tests:

- Lifetime testing: Accelerated aging (e.g., 85°C/85% RH for 1,000 hours).

- Mechanical stress: Flexibility/folding endurance (100,000+ cycles for foldables).

- Environmental resistance: UV exposure, humidity, and thermal shock testing.

- Performance metrics:

- Luminance retention: >90% brightness after 10,000 hours.

- Color stability: Delta E < 3 for consistent color accuracy.

- Supplier accountability: Reputable manufacturers provide test reports and warranties (e.g., 2–5 years).

5.What industries benefit most from custom OLEDs?

- Consumer electronics: Smartphones, wearables, tablets.

- Industrial/medical: Control panels, diagnostic displays.

- Automotive: Dashboard screens, infotainment systems.

- Retail/entertainment: Digital signage, AR/VR headsets.