Engineering Guide for Product Designers, OEM/ODM Teams & Procurement

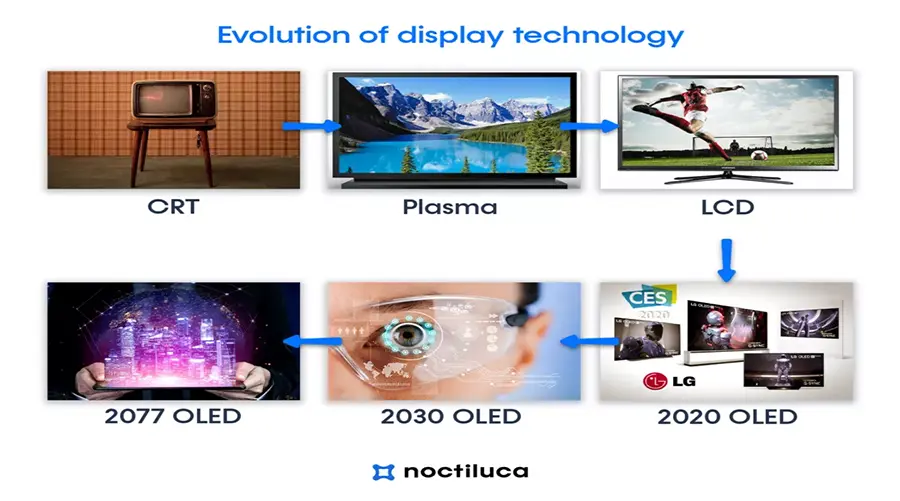

Selecting the right display module is a critical decision that impacts your product’s user experience, industrial design, power budget, reliability, and total cost of ownership. In 2025, OLED and TFT LCD remain the two dominant display technologies for embedded applications—from wearables to automotive cockpits. This guide provides a detailed, engineer-focused comparison to help you choose the optimal solution for your next project.

1. Introduction — Why Display Selection Matters

The role of displays in modern IoT, industrial, automotive, and consumer devices

Today’s displays are no longer passive output devices—they’re central to user interaction, brand perception, and system efficiency. Whether it’s a medical monitor showing vital signs or a factory HMI controlling machinery, the display directly affects usability, safety, and service life.

Why OLED and TFT LCD are the two mainstream module technologies

While MicroLED and E-Ink serve niche roles, OLED (Organic Light-Emitting Diode) and TFT LCD (Thin-Film Transistor Liquid Crystal Display) dominate mid-to-high-end embedded markets due to mature manufacturing, scalable sizes (1”–15”), and flexible integration options.

Overview of selection challenges

Key trade-offs include:

- Power consumption under real-world UI patterns

- Sunlight readability vs indoor contrast

- Risk of image retention (burn-in)

- Mechanical constraints (curved, ultra-thin, rugged)

- Total cost at volume (including yield and supply stability)

2. What Is an OLED Display Module?

Definition: self-emissive organic diode display

An OLED display generates light directly from organic emissive layers—no backlight required. Each pixel emits its own light and can be turned completely off, enabling true black and infinite contrast.

Structure: TFT backplane + organic layers + encapsulation

Modern OLED modules use an active-matrix (AMOLED) architecture with a low-temperature polysilicon (LTPS) or oxide (IGZO) TFT backplane to drive individual pixels. The organic stack is sealed with thin-film encapsulation (TFE) to prevent moisture/oxygen ingress.

Variants: AMOLED / Flexible OLED / Transparent OLED

While PMOLED exists for tiny indicators, most B2B applications use AMOLED. Advanced variants include:

- Flexible OLED: polymer substrate enables curved or foldable designs

- Transparent OLED: used in retail showcases and AR HUDs

Typical module integration

A complete OLED module includes:

- FPC (flexible printed circuit) with driver IC

- On-cell or OGS touch sensor (optional)

- Cover glass with AR/AG coating

- Circular polarizer for glare reduction

3. What Is a TFT LCD Module?

Definition: liquid crystal + backlight architecture

TFT LCD uses a liquid crystal layer to modulate light from a separate backlight unit (BLU). Pixels don’t emit light—they act as shutters.

Structure: TFT matrix + LC cell + polarizers + backlight unit (BLU)

The core stack includes:

- Color filter + LC layer sandwiched between glass substrates

- Two polarizers (front/back)

- LED-based edge-lit or direct-lit backlight

- TFT array for pixel control (a-Si, LTPS, or IGZO)

IPS / VA / TN LCD differences

- IPS (In-Plane Switching): best viewing angles and color accuracy; common in premium HMIs

- VA (Vertical Alignment): higher contrast than IPS but narrower viewing angle

- TN (Twisted Nematic): low cost, fast response, poor color/viewing—rare in new designs

Integration components

Standard TFT LCD modules include:

- LED backlight with diffuser/optical films

- FPC with timing controller (T-Con)

- Optional resistive/capacitive touch layer

- Chemically strengthened cover glass

4. Key Technical Differences (OLED vs TFT LCD)

The table below summarizes critical performance parameters:

| Parameter | OLED Display Module | TFT LCD Module |

|---|---|---|

| Light-emitting mechanism | Self-emissive (no backlight) | Requires LED backlight |

| Thickness | 0.5–1.2 mm (ultra-thin) | 2.5–5.0 mm (due to BLU stack) |

| Black level & contrast | True black, ∞:1 (typ. 1,000,000:1) | Grayish black, 1,000:1–5,000:1 (IPS), up to 10,000:1 (VA) |

| Brightness (typical) | 300–800 nits (indoor); up to 1,200+ nits (auto/outdoor) | 500–1,500+ nits (easily scalable for sunlight) |

| Color gamut | DCI-P3 95–100% standard | sRGB 100% typical; DCI-P3 with quantum dot (QD-LCD) |

| Response time | 0.1–1 ms (excellent for motion) | 5–25 ms (motion blur possible) |

| Viewing angle | ±85° with minimal shift | IPS: ±80°; VA: ±60° (color/brightness shift) |

| Power (dark UI) | Very low (black = off) | Constant (backlight always on) |

| Power (white UI) | Higher than LCD | Lower than OLED |

| Lifespan | Blue sub-pixel degrades faster; T95 ~15,000–30,000 hrs | Backlight decay over time; >50,000 hrs typical |

| Burn-in risk | Yes (with static high-brightness content) | No |

| Operating temp (industrial) | -30°C to +70°C (standard); -40°C to +85°C (auto-grade) | -30°C to +85°C widely available |

| Form factor | Flexible, curved, transparent options | Rigid only |

| Cost (at 5–7”) | Higher (20–50% premium) | Lower, highly competitive |

5. Advantages of OLED Display Modules

- Ultra-high contrast: perfect blacks enhance HDR and visual depth

- Thinner and lighter: enables slimmer bezels and sleeker product profiles

- Fast response: ideal for dynamic UIs, video, gaming, and AR/VR

- Design freedom: supports curved, flexible, and transparent implementations

- Wide viewing angle: consistent color and brightness even at extreme angles

- Energy-efficient on dark UIs: critical for battery-powered devices

6. Advantages of TFT LCD Modules

- Higher peak brightness: better for outdoor or sunlit environments

- No burn-in: safe for static content (e.g., industrial gauges, status panels)

- Lower cost: especially for sizes >5”, with stable pricing at scale

- Wider temperature range: industrial-grade LCDs operate reliably from -40°C to +85°C

- Long-term stability: proven in 10+ year deployments (e.g., medical, kiosks)

- Mature supply chain: multiple panel makers, short lead times, easy alternates

7. Application Scenarios: Which Technology Fits Your Product?

- Consumer electronics: Smartphones, smartwatches → OLED preferred for aesthetics and power savings.

- Automotive displays: Center stacks → OLED (design); Instrument clusters → High-brightness LCD or auto-grade OLED with compensation.

- Industrial HMI: Factory machines, test equipment → TFT LCD (static UI, sunlight, reliability).

- Medical devices: Non-diagnostic monitors → OLED for contrast; Diagnostic imaging → calibrated LCD.

- Retail signage: Transparent shop windows → Transparent OLED; Outdoor billboards → High-brightness LCD.

- IoT devices: Battery-powered sensors with simple UI → OLED if dark-themed; Always-on white UI → LCD.

- AR/VR: Near-eye displays → Micro-OLED (not covered here, but derived from OLED tech).

8. Cost Analysis: OLED vs TFT LCD

Module cost by size (approximate, 2025)

- 2.4”: OLED ≈ $8–12 | LCD ≈ $3–5

- 5.0”: OLED ≈ $15–25 | LCD ≈ $6–10

- 10.1”: OLED ≈ $40–70 | LCD ≈ $15–25

Factors influencing pricing

- Backplane type: LTPS OLED > IGZO LCD > a-Si LCD

- Brightness: 1,000+ nits adds 15–30% cost

- Touch integration: On-cell OLED vs add-on touch for LCD

- Yield rate: OLED yield lower on large/flexible panels

- Supply chain: LCD has more vendors; OLED dominated by Samsung/LG/BOE

Long-term cost considerations

While OLED has higher upfront cost, it may reduce system-level expenses (e.g., thinner housing, smaller battery for dark UI). However, for high-volume, static-content products, LCD remains more economical.

9. Reliability & Lifespan Considerations

- OLED burn-in: Mitigate via pixel shifting, logo dimming, and ABL (Automatic Brightness Limiter).

- Luminance decay: Track T95 (time to 95% initial brightness)—typically 15k–30k hours for OLED.

- LCD backlight decay: Yellowing or dimming after 30k–50k hours; replaceable in some systems.

- Temperature performance: OLED efficiency drops at low temps; LCD response slows below -20°C.

- Moisture sensitivity: OLED requires hermetic TFE; LCD is less sensitive but still needs sealing.

10. Engineering Selection Guide (Checklist)

Ask these questions before finalizing your display:

- Will the UI be mostly dark or white/static?

- What is the ambient lighting condition? (Indoor / outdoor / variable?)

- Do you need curved, flexible, or transparent form factors?

- What is your power budget per hour/day?

- What is the expected product lifetime? (2 years vs 10 years?)

- Do you require touch? On-cell or add-on?

- What interface does your SoC support? (MIPI DSI, LVDS, eDP, SPI?)

- What is your target BOM cost per unit at 10k/50k/100k volume?

- Will the device operate in extreme temperatures or high humidity?

11. Conclusion — Which Is Better for Your Product?

- ✅ Choose OLED if: design elegance, contrast, thinness, fast motion, or dark UI power savings are priorities.

- ✅ Choose TFT LCD if: you need high brightness, static content, wide temperature range, lower cost, or long-term field stability.

- 💡 In 2025, both technologies have robust supply chains—your choice should be driven by application requirements, not hype.

12. CTA — Contact Us for OLED / LCD Modules (OEM/ODM Support)

We supply industrial-grade OLED and TFT LCD display modules from 1.5” to 15”, with full customization options:

- ✅ Full datasheets & interface specifications (MIPI, LVDS, SPI, eDP)

- ✅ Free engineering samples for validation

- ✅ Custom sizes, cutouts, brightness, touch, and FPC routing

- ✅ Long-term supply assurance with EOL notification policy

Request a Quote & Sample Today

FAQ (B2B Engineer Questions)

Can OLED displays be used in industrial environments?

Yes—with proper encapsulation, thermal management, and UI design. Industrial-grade OLEDs now support -30°C to +70°C operation.

Does OLED really save power?

Only if your UI uses dark backgrounds. A full-white screen on OLED consumes more power than LCD. Model power using your actual UI pattern.

How do I prevent OLED burn-in in a status display?

Use techniques like periodic pixel shift, dynamic brightness limiting, hiding static elements after timeout, and avoiding pure-white icons.

Is MIPI DSI supported on both OLED and LCD?

Yes—most modern AMOLED and TFT LCD modules support MIPI DSI. Verify bandwidth and timing compatibility with your host processor.

Can I get a curved LCD?

No—LCDs are rigid due to glass substrates and liquid crystal physics. Only OLED supports true curvature.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。