On this page: Overview | Why Custom Bar LCD Displays | Customization Options | Typical Applications | Customization Process | Key Considerations | Summary

Overview

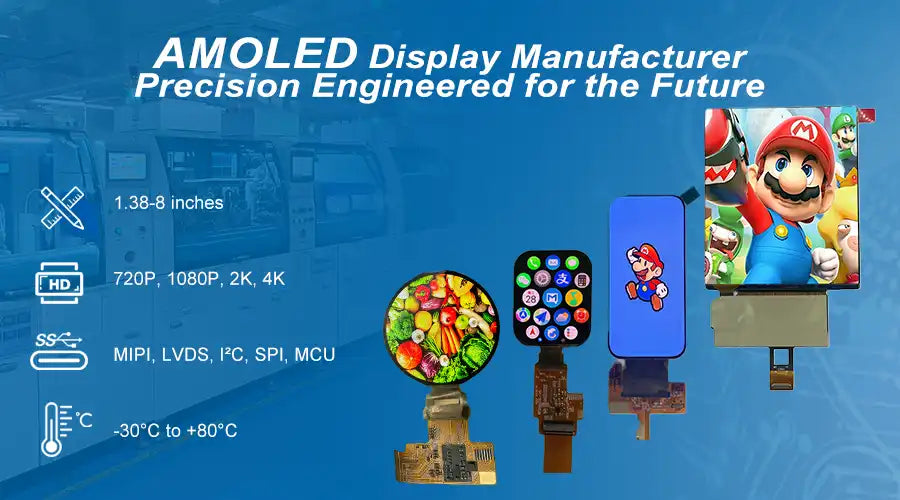

Stretched Bar LCD displays—also known as ultra-wide or bar-type LCDs—are increasingly used in retail signage, transportation systems, industrial equipment, and smart commercial environments. Unlike standard 16:9 displays, bar LCDs feature non-traditional aspect ratios such as 16:3, 24:5, or even wider formats.

For many B2B projects, off-the-shelf products are not sufficient. This is where custom stretched bar LCD displays become essential. Customization allows brands, system integrators, and OEM customers to tailor the display’s size, performance, interface, and mechanical design to specific project requirements.

Why Choose a Custom Stretched Bar LCD Display?

While standard bar LCD sizes work for general digital signage, many professional applications require precise alignment, system compatibility, or environmental performance. Custom bar LCD displays help solve these challenges by offering:

- Perfect fit for unique installation spaces

- Optimized brightness and contrast for specific lighting conditions

- Seamless integration with existing hardware and software systems

- Long-term supply stability for commercial and industrial deployments

For shelf-edge displays, transportation signage, or embedded systems, customization is often not optional—it is a requirement.

What Can Be Customized in a Stretched Bar LCD?

1. Display Size & Aspect Ratio

Custom bar LCD displays can be produced in a wide range of diagonal sizes, commonly from 8.6 inch up to 86 inch, with non-standard aspect ratios tailored to your application. Typical customization includes:

- Exact diagonal size and active area

- Ultra-wide or narrow height formats

- Special cut or elongated panel designs

2. Resolution & Pixel Configuration

Resolution can be customized to balance clarity, cost, and system bandwidth. Common configurations include:

- High-definition stretched resolutions (e.g. 1920×360, 3840×600)

- Custom pixel mapping for advertising or data visualization

- Optimized PPI for close-view or long-distance viewing

3. Brightness & Optical Performance

Brightness is one of the most critical parameters for bar LCD displays. Custom options typically include:

- Standard indoor brightness (300–500 nits)

- High brightness versions (700–1500 nits) for strong ambient light

- Anti-glare (AG), anti-reflection (AR), or bonded cover glass

4. Interface & Signal Input

To ensure compatibility with your control system, bar LCD displays can be customized with various interfaces, including:

- HDMI / HDMI 2.0

- LVDS (single or dual channel)

- eDP

- VGA or DVI (legacy systems)

Signal timing, orientation, and firmware can also be adjusted for non-standard resolutions.

5. Integrated System (Android / Media Player)

Many customers choose Android-based stretched bar LCD displays for plug-and-play digital signage. Customization options include:

- Android OS version and chipset selection

- Internal storage and RAM configuration

- Auto-play, USB update, or remote CMS support

6. Mechanical Design & Housing

Mechanical customization ensures reliable installation and long-term operation:

- Metal or aluminum housing design

- Custom mounting brackets or VESA patterns

- Ultra-slim or open-frame designs for embedded use

7. Environmental & Reliability Specifications

For industrial and commercial projects, custom bar LCD displays can be engineered to meet specific environmental requirements:

- Extended operating temperature ranges

- 24/7 continuous operation

- ESD, EMC, and vibration resistance

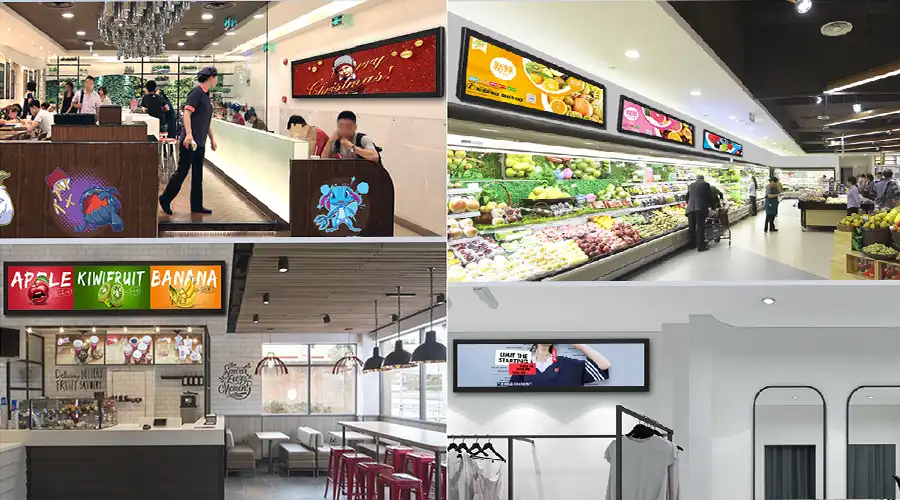

Typical Applications for Custom Bar LCD Displays

- Retail shelf-edge pricing and promotion displays

- Transportation signage in buses, subways, and trains

- Smart vending machines and kiosks

- Industrial control panels and monitoring systems

- Elevator, wayfinding, and public information displays

How the Customization Process Works

A typical custom stretched bar LCD project follows these steps:

- Requirement definition (size, brightness, interface, quantity)

- Technical evaluation and proposal

- Sample or prototype development

- Testing and system validation

- Mass production and long-term supply support

Early communication between the display supplier and system integrator is critical to reduce development time and risk.

Key Considerations Before Customizing

- Minimum order quantity (MOQ) and lead time

- Long-term availability of panels and components

- System compatibility and power requirements

- After-sales support and replacement strategy

Summary

Custom stretched bar LCD displays offer unmatched flexibility for modern digital signage and embedded display projects. By tailoring size, brightness, interface, system integration, and mechanical design, businesses can achieve optimal performance and visual impact while ensuring long-term reliability.

If your project requires a non-standard display solution, a custom bar LCD is often the most efficient and scalable choice.

Contact us to discuss your custom stretched bar LCD display requirements and receive a technical proposal.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。