Our Quality Statement

Quality Control System

Quality is our top priority at BROWNLN Company. We have a dedicated quality management team, advanced inspection equipment, and a strict quality control system in place to ensure that every product that leaves our factory meets our high standards of quality and reliability.

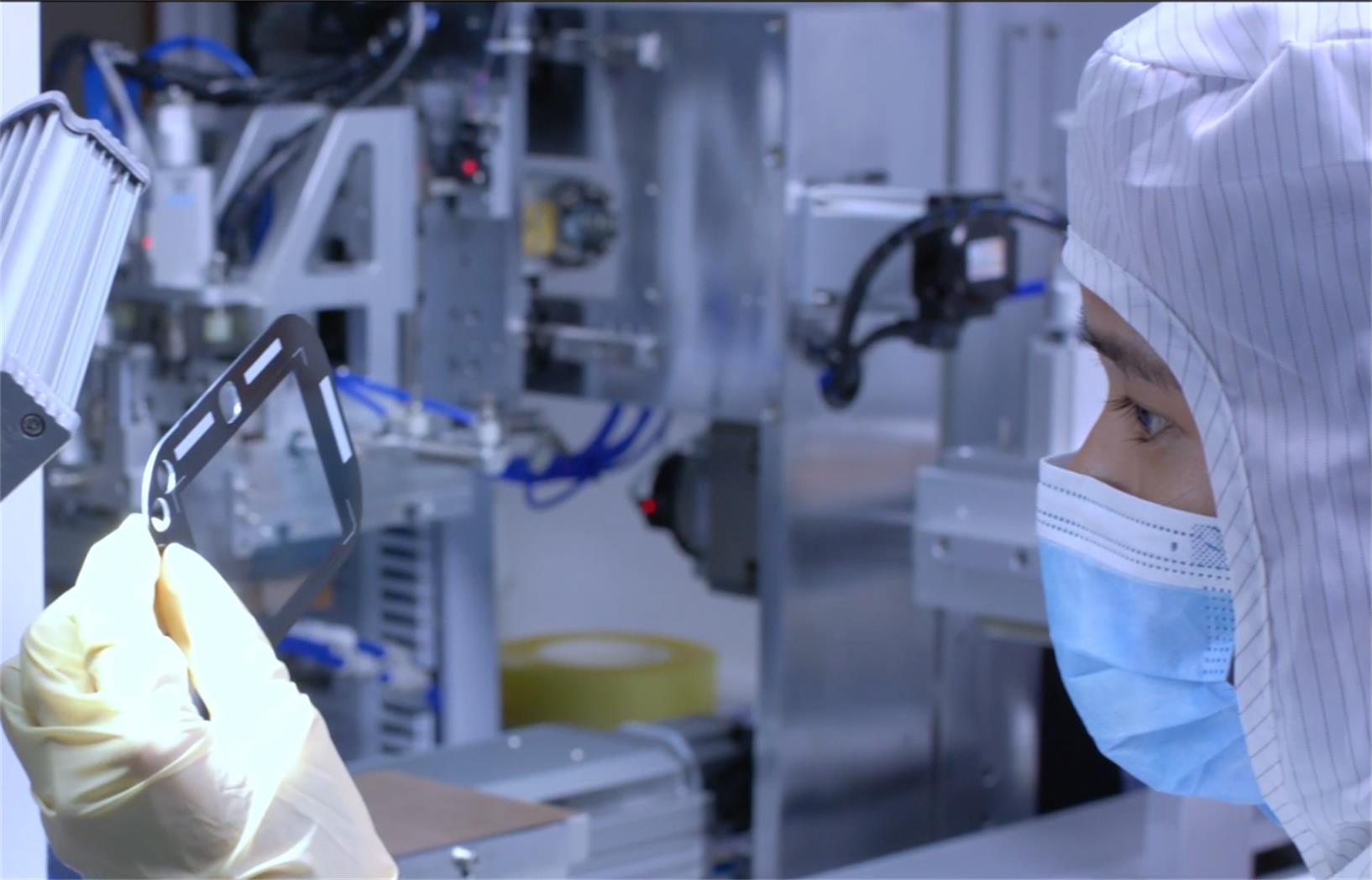

Professional Quality Management Team

We have a professional quality management team with members who have rich industry experience and expertise. They are responsible for supervising and managing the quality control work throughout the production process, ensuring that every step meets strict quality standards. Additionally, the team undergoes regular training and learning to continuously improve their professional skills and abilities.

Strict Quality Inspection Process

Our quality inspection process is rigorous and comprehensive, including multiple levels of inspection steps. Each TFT module undergoes multiple inspections during the production process, including visual inspection, functionality testing, environmental and reliability testing, part number and quantity verification, datasheet validation, and 100% inspection where required. We also follow MIL STD 1916 and ANSI/ASQ Z1.4 sampling for quality assurance. Only products that pass all inspections can proceed to the next production step, ensuring the quality of every product that leaves our factory.

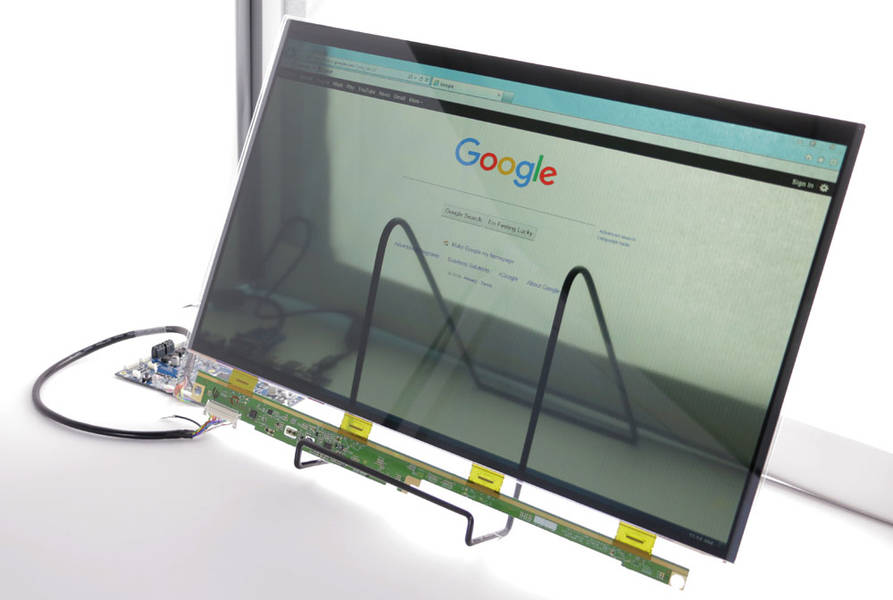

Advanced Inspection Equipment

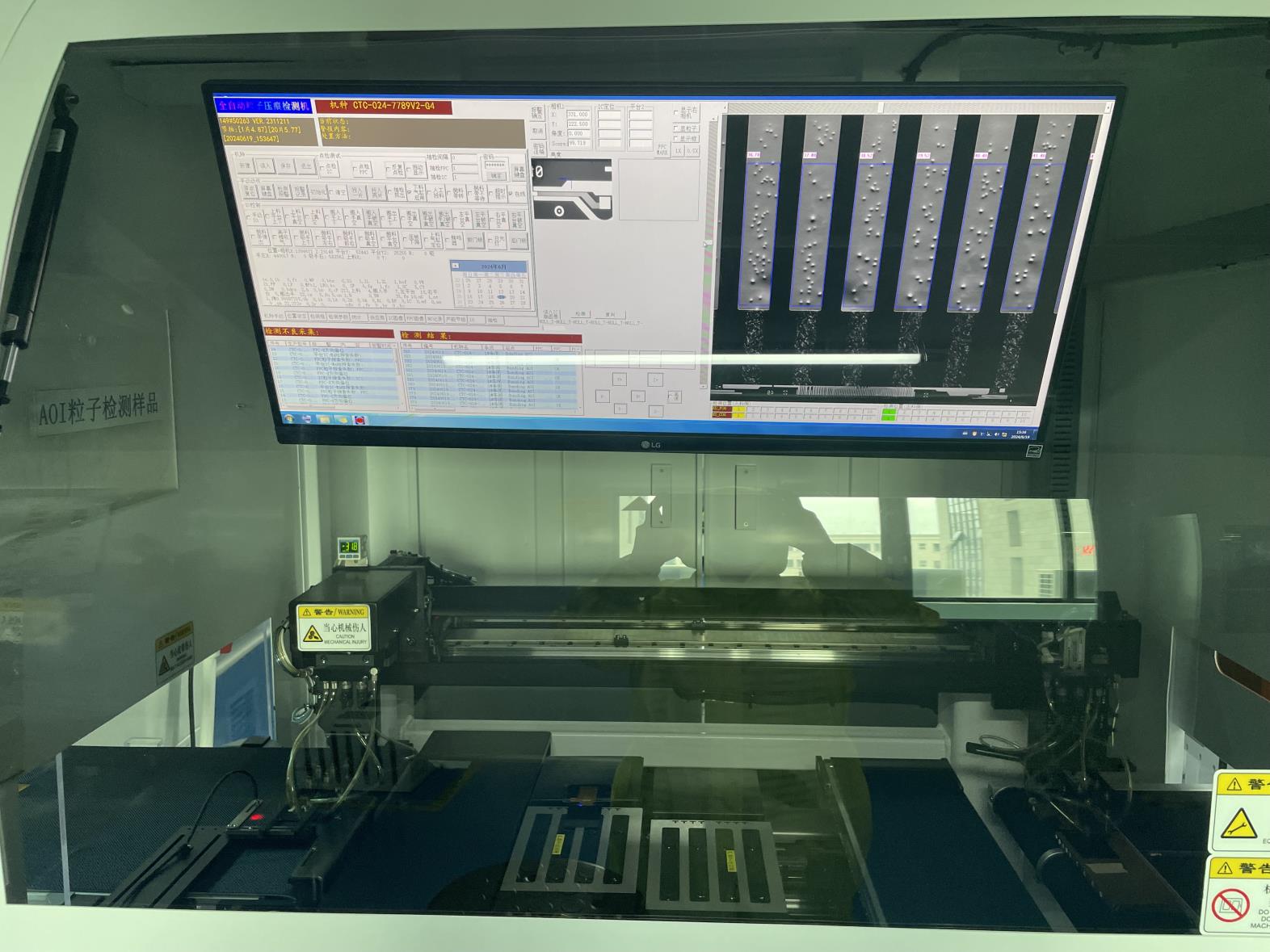

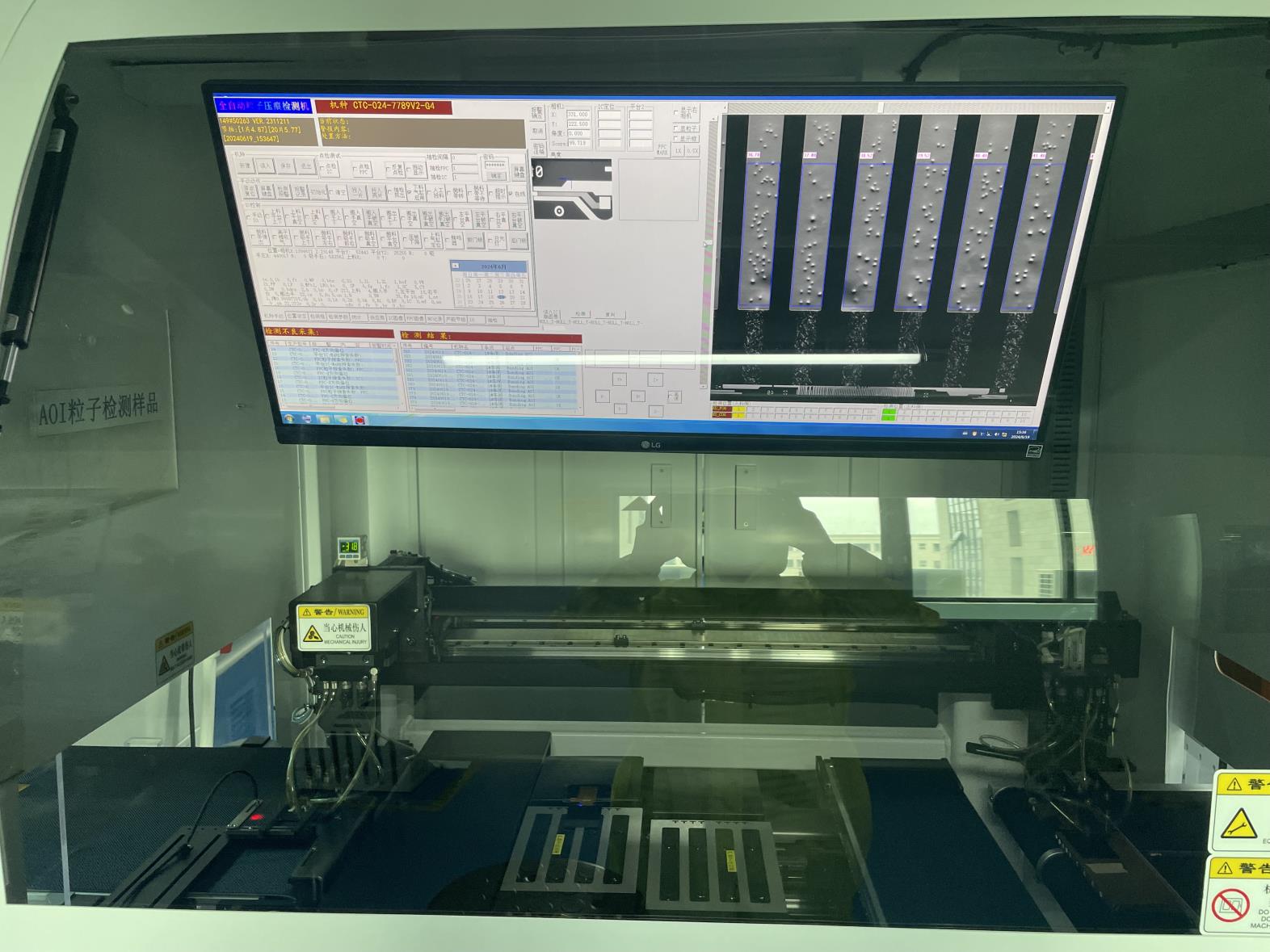

Our company utilizes state-of-the-art inspection equipment to ensure the accuracy and reliability of every inspection. Our advanced equipment includes high-precision automated optical inspection (AOI) machines, functionality testing equipment, and environmental test chambers. By using AOI technology instead of manual inspection, we eliminate human fatigue and significantly reduce the risk of human error. With AOI testing, our products have a defect rate of less than 300 PPM, which greatly improves the quality and accuracy of our products. The AOI machines can detect tiny defects as small as 5μm for spots and 50μm for foreign objects. They also accurately detect mura defects with a 2% gray screen, low contrast color defects with a precision of ±0.0002, and various other defects such as bright/dark spots, lines, backlight foreign objects, display anomalies, edge light leakage, color temperature deviation, and mura defects.

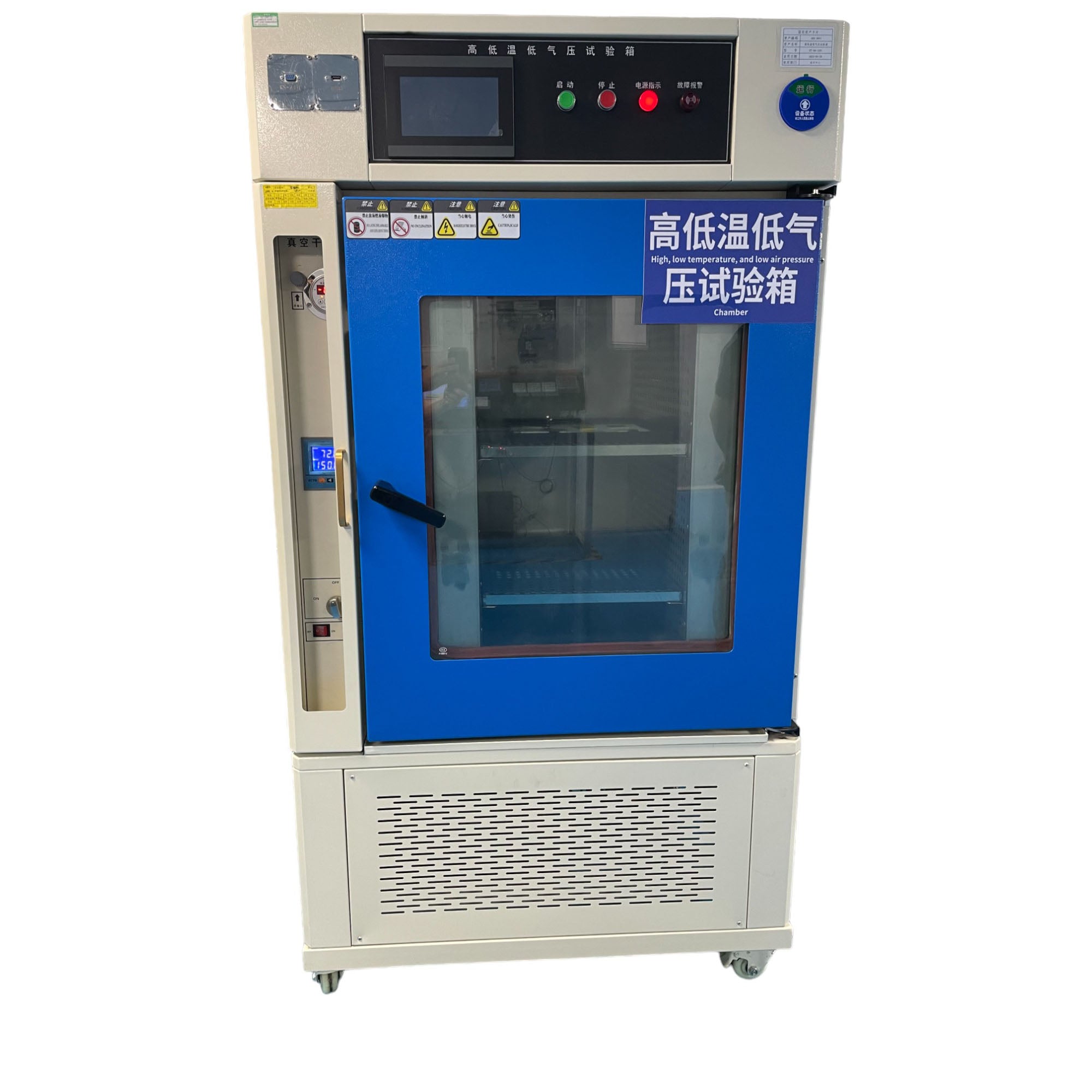

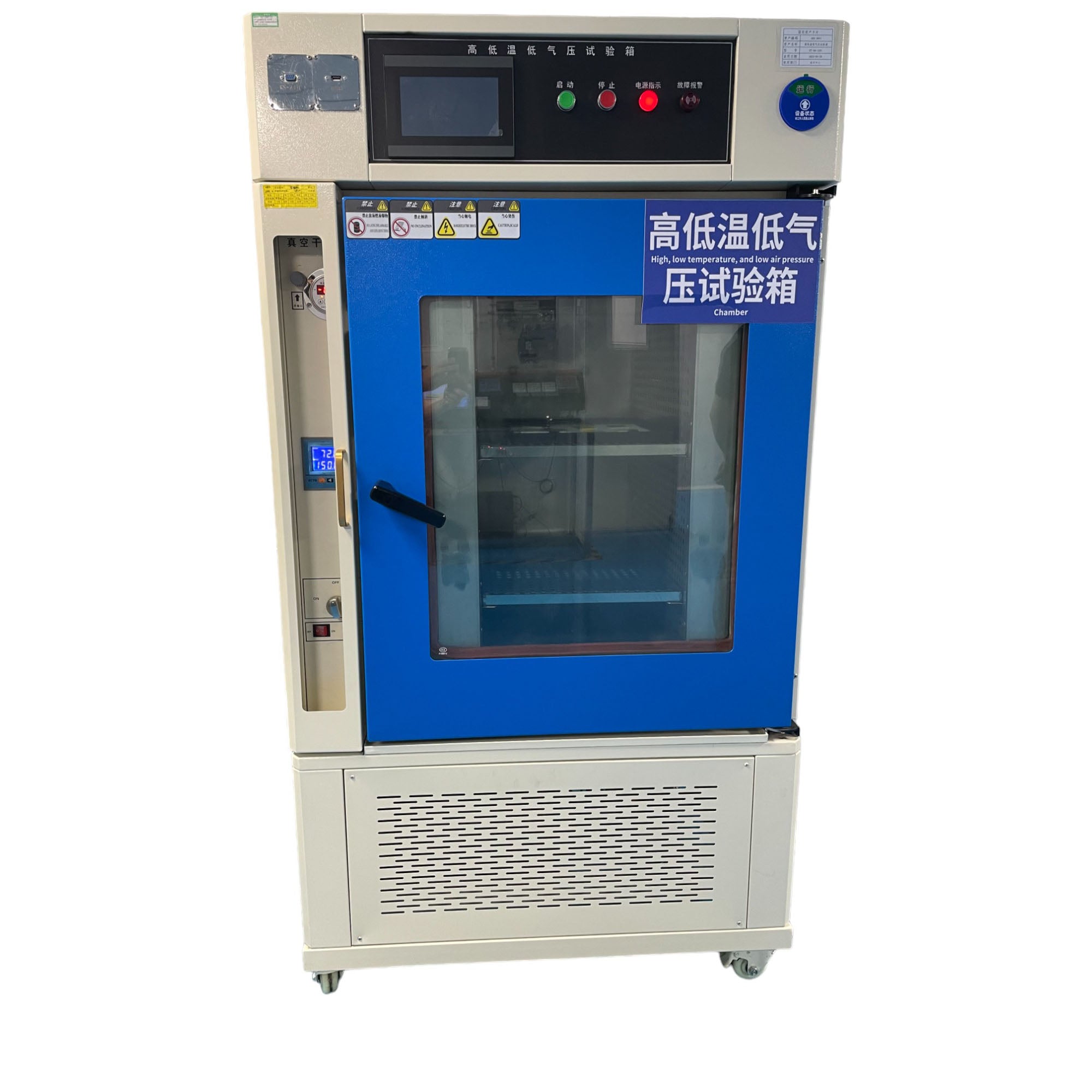

Environmental Monitoring and Reliability Testing

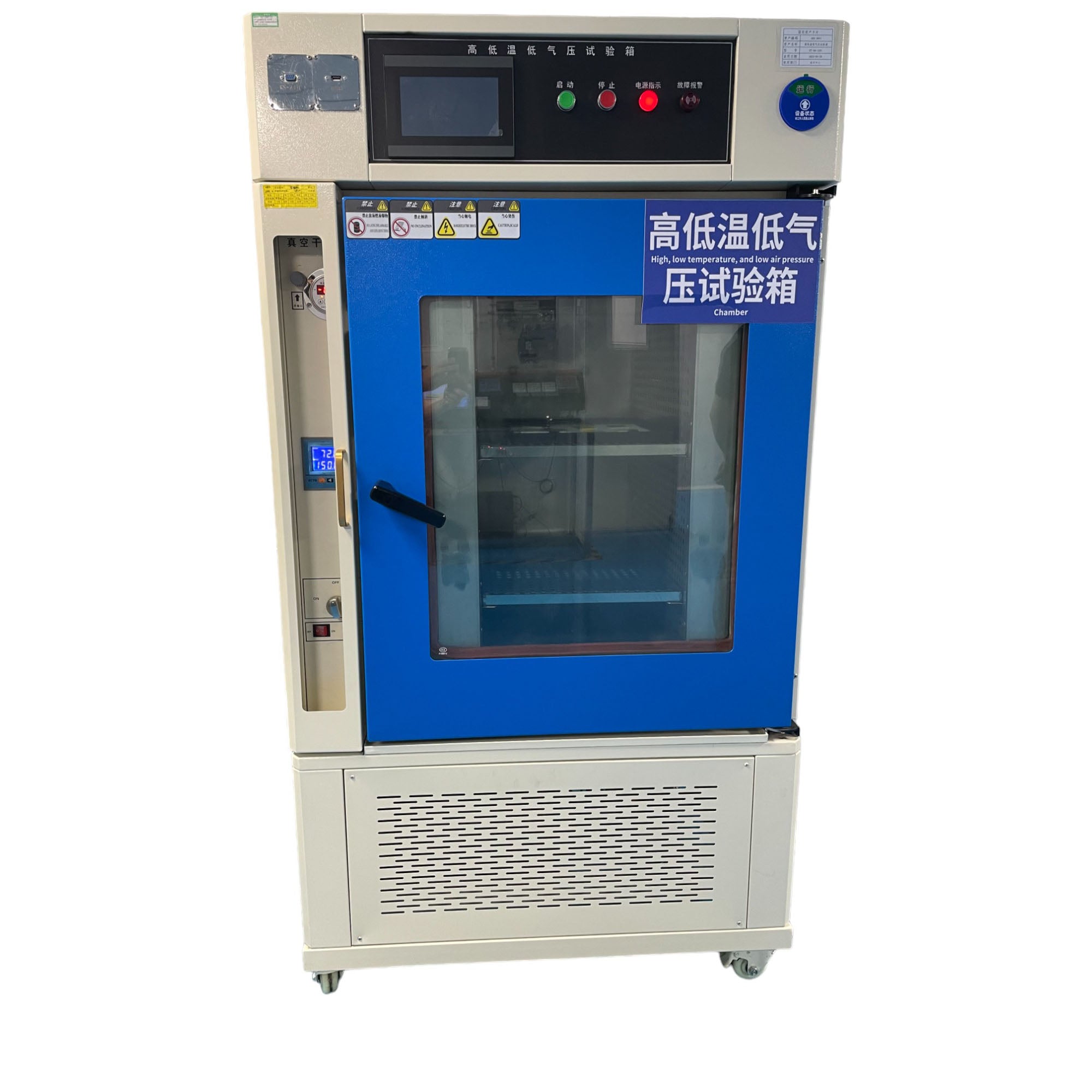

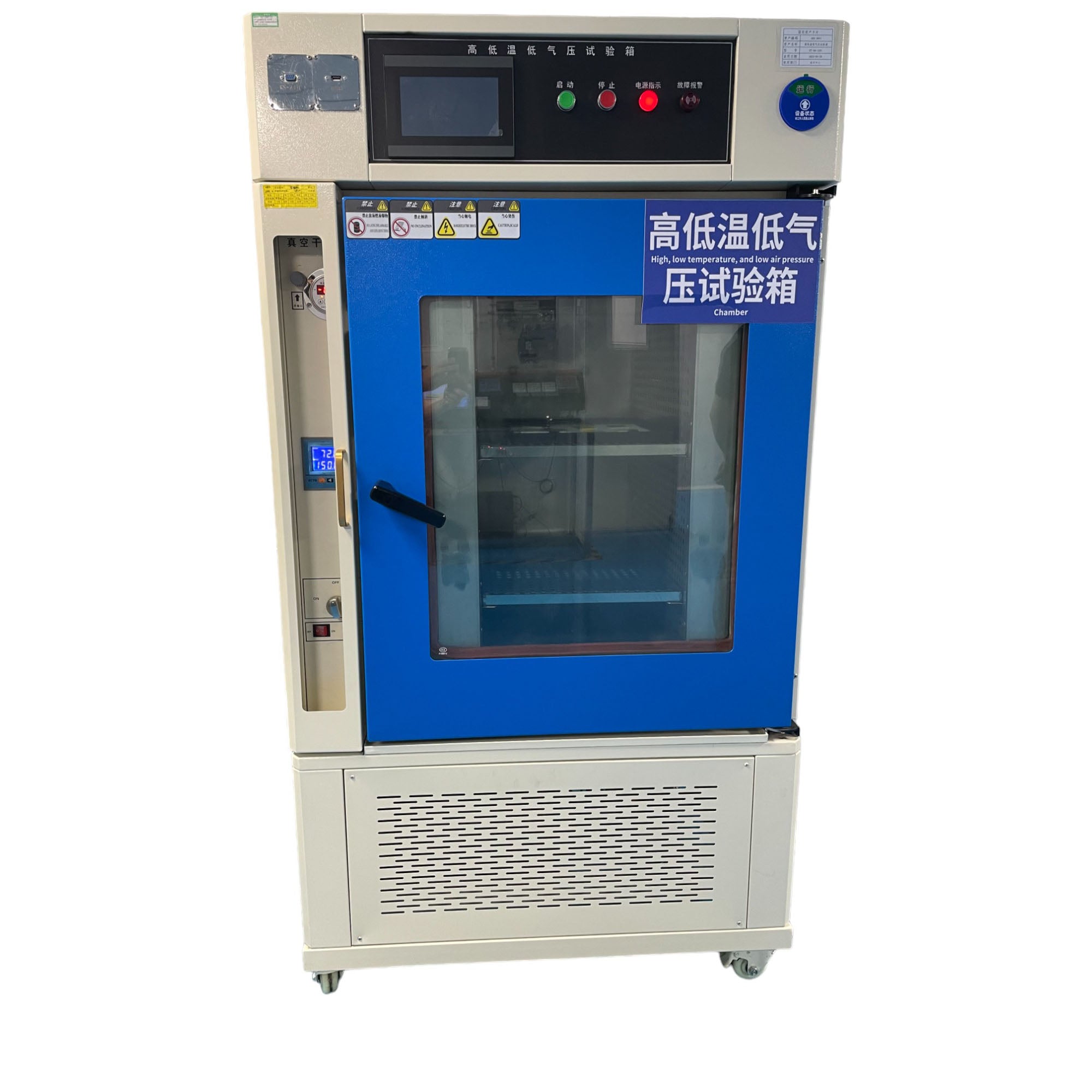

To ensure the reliability and stability of our TFT modules in various environments, we conduct comprehensive environmental monitoring and reliability testing. These tests include high-temperature and high-humidity testing, low-temperature testing, vibration testing, drop testing, and more, simulating various extreme conditions that the product may encounter in real-world use. Through these tests, we can guarantee that our products perform well in all kinds of environments.

Quality Control Laboratory Introduction

Our quality control laboratory is equipped with advanced inspection equipment and staffed by professional technicians who are responsible for conducting comprehensive quality testing and analysis of TFT modules. The laboratory strictly operates in accordance with international standards to ensure the accuracy and reliability of every test result. We also continuously innovate and improve our techniques to enhance our testing capabilities and level of expertise.

Our inspection equipment

Our quality inspection equipment includes six fully automated production lines, each equipped with online particle AOI inspection equipment and automatic LCM defect AOI inspection systems. These devices utilize high-resolution imaging technology and advanced image processing algorithms to accurately detect small particles and pressure marks on the surface of the product, including those from FPC/IC bonding. They also achieve 100% inspection of particle quantity and positional deviation, ensuring that our products meet the highest standards of quality. Through the use of these advanced devices, we can guarantee the quality and reliability of our products, providing our customers with dependable products.

Our inspection equipment includes six fully automated production lines with online particle AOI and automatic LCM defect AOI systems. These advanced devices accurately detect small particles and pressure marks on the product surface, achieving 100% inspection of particle quantity and positional deviation for all COG and FOG products. This ensures the highest quality standards for our products.

Our inspection equipment includes six fully automated production lines with online particle AOI and automatic LCM defect AOI systems. These advanced devices accurately detect small particles and pressure marks on the product surface, achieving 100% inspection of particle quantity and positional deviation for all COG and FOG products. This ensures the highest quality standards for our products.

Our AOI inspection equipment is designed to replace manual inspection, eliminating the impact of human fatigue and significantly reducing the likelihood of human error. After undergoing AOI testing, our products have a functional failure rate of less than 300 PPM, greatly improving product quality. Our systems can accurately detect various defects, including point defects (bright or dark spots) with a size of 5μm, foreign object defects with a size of 50μm, 2% detection accuracy for Mura defects on gray screens, and ±0.0002 accuracy for low contrast color defects. They can also detect a variety of other defects, such as line defects, backlit foreign objects, display abnormalities, edge light leakage, color temperature deviation, and various types of Mura defects.

Our AOI inspection equipment is designed to replace manual inspection, eliminating the impact of human fatigue and significantly reducing the likelihood of human error. After undergoing AOI testing, our products have a functional failure rate of less than 300 PPM, greatly improving product quality. Our systems can accurately detect various defects, including point defects (bright or dark spots) with a size of 5μm, foreign object defects with a size of 50μm, 2% detection accuracy for Mura defects on gray screens, and ±0.0002 accuracy for low contrast color defects. They can also detect a variety of other defects, such as line defects, backlit foreign objects, display abnormalities, edge light leakage, color temperature deviation, and various types of Mura defects.

Our comprehensive Inspection Process

At BROWNLH, quality control is a crucial part of the production process. In order to ensure that each TFT display module meets the highest quality standards, we have implemented a comprehensive and strict inspection process. Here are the eight key inspection methods we perform during the production process:

Our Reliability Testing Process

At our company, we believe in delivering the best performance and reliability to our customers. That is why we employ a comprehensive testing process for all our products before shipping them out. This includes the various methods and key points mentioned above, as well as any additional quality testing processes that may be required for certain displays. With our rigorous testing measures, we can ensure that our customers receive top-quality and reliable products from us.

- High Temperature Storage Test conditions: 85℃±3℃ for 1000 hours, with a relative humidity of no more than 45%.

- After the storage period, the product is restored for 2 hours at 25℃.

- A non-operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-2 and GB2423.2.

- The test is conducted using a Programmable High Temperature Tester.

- High Temperature Storage Test conditions: 85℃±3℃ for 1000 hours, with a relative humidity of no more than 45%.

- After the storage period, the product is restored for 2 hours at 25℃.

- A non-operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-2 and GB2423.2.

- The test is conducted using a Programmable High Temperature Tester.

- Low Temperature Storage Test conditions: -40℃±3℃ for 1000 hours.

- After the storage period, the product is restored for 2 hours at 25℃.

- A non-operation check is conducted.

- During the temperature range of -40℃ to -30℃, the operating performance is not guaranteed.

- However, as long as there is no functional damage, the check is considered OK.

- This test is in accordance with the following specifications: IEC60068-2-1 and GB2423.1.

- The test is conducted using the necessary equipment and tools.

- Low Temperature Storage Test conditions: -40℃±3℃ for 1000 hours.

- After the storage period, the product is restored for 2 hours at 25℃.

- A non-operation check is conducted.

- During the temperature range of -40℃ to -30℃, the operating performance is not guaranteed.

- However, as long as there is no functional damage, the check is considered OK.

- This test is in accordance with the following specifications: IEC60068-2-1 and GB2423.1.

- The test is conducted using the necessary equipment and tools.

- High Temperature Operation Test conditions: 85℃±3℃ for 1000 hours.

- After the operation period, the product is restored for 2 hours at 25℃.

- An operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-2 and GB2423.2.

- The test is conducted using a Programmable High Temperature Tester.

- High Temperature Operation Test conditions: 85℃±3℃ for 1000 hours.

- After the operation period, the product is restored for 2 hours at 25℃.

- An operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-2 and GB2423.2.

- The test is conducted using a Programmable High Temperature Tester.

- Low Temperature Operation Test conditions: -30℃±3℃ for 1000 hours.

- After the operation period, the product is restored for 2 hours at 25℃.

- An operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-1 and GB2423.1.

- The test is conducted using a Programmable Low Temperature Tester.

- Low Temperature Operation Test conditions: -30℃±3℃ for 1000 hours.

- After the operation period, the product is restored for 2 hours at 25℃.

- An operation check is conducted to ensure the product is still functioning properly.

- This test is in accordance with the following specifications: IEC60068-2-1 and GB2423.1.

- The test is conducted using a Programmable Low Temperature Tester.

- High Temperature & Humidity Operation Test conditions: 85℃±2℃ and 85±2%RH for 1000 hours.

- After the operation period, the product is left at room temperature for 2 hours before being checked for functionality.

- This test is in accordance with the following specifications: IEC60068-2-78 and GB/T2423.3.

- The test is conducted using a Constant Temperature and Humidity Tester.

- High Temperature & Humidity Operation Test conditions: 85℃±2℃ and 85±2%RH for 1000 hours.

- After the operation period, the product is left at room temperature for 2 hours before being checked for functionality.

- This test is in accordance with the following specifications: IEC60068-2-78 and GB/T2423.3.

- The test is conducted using a Constant Temperature and Humidity Tester.

- Thermal Shock Test conditions: -40°C for 30 minutes, then a change to +85°C for 5 minutes, and finally back to -40°C for another 30 minutes, for a total of 1000 cycles.

- The product is non-operational during this test and starts with a cold temperature and ends with a high temperature.

- This test is in accordance with the following specifications: IEC60068-2-14 and GB2423.22.

- The test is conducted using a Thermal Shock Tester.

- Thermal Shock Test conditions: -40°C for 30 minutes, then a change to +85°C for 5 minutes, and finally back to -40°C for another 30 minutes, for a total of 1000 cycles.

- The product is non-operational during this test and starts with a cold temperature and ends with a high temperature.

- This test is in accordance with the following specifications: IEC60068-2-14 and GB2423.22.

- The test is conducted using a Thermal Shock Tester.

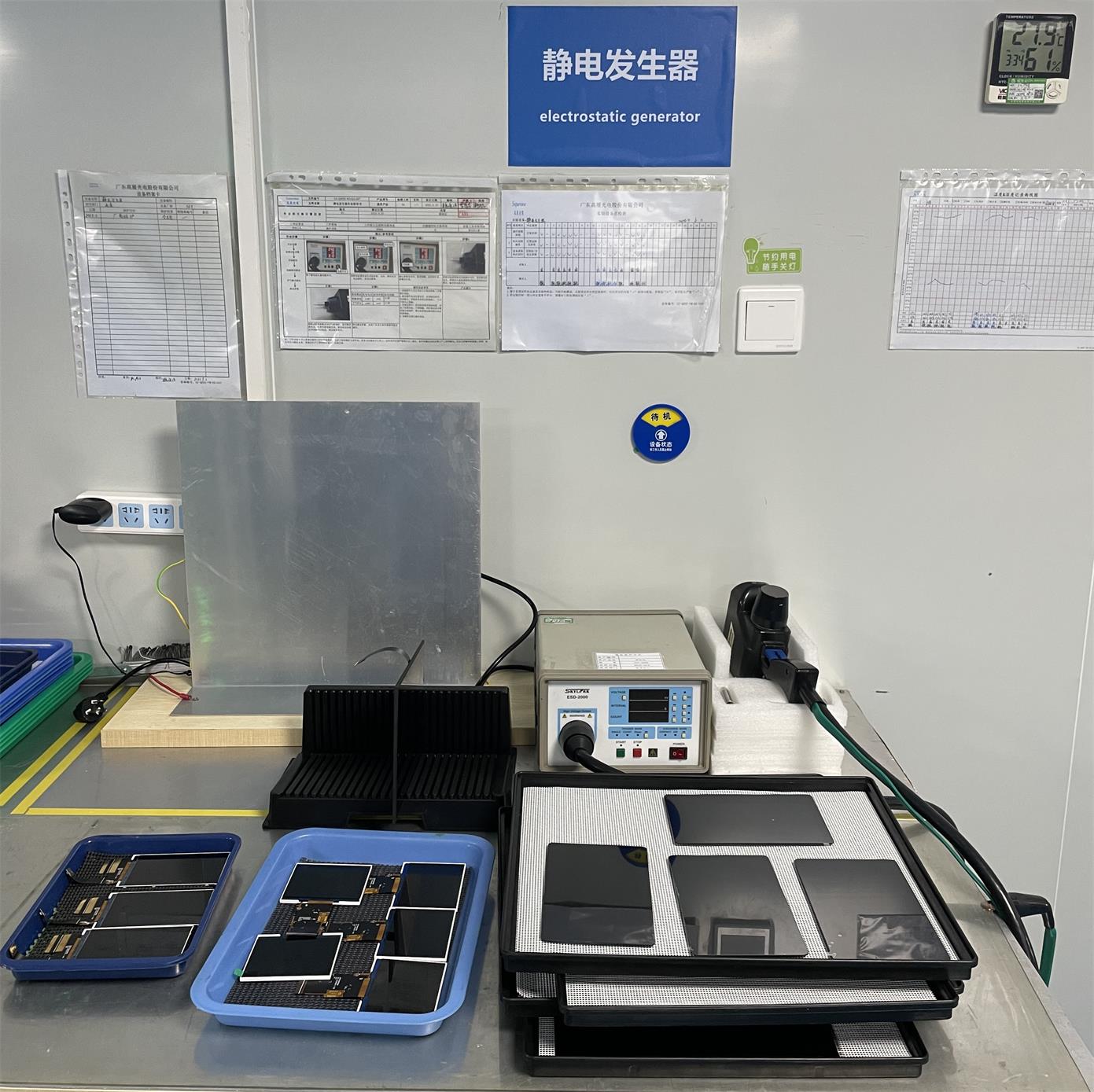

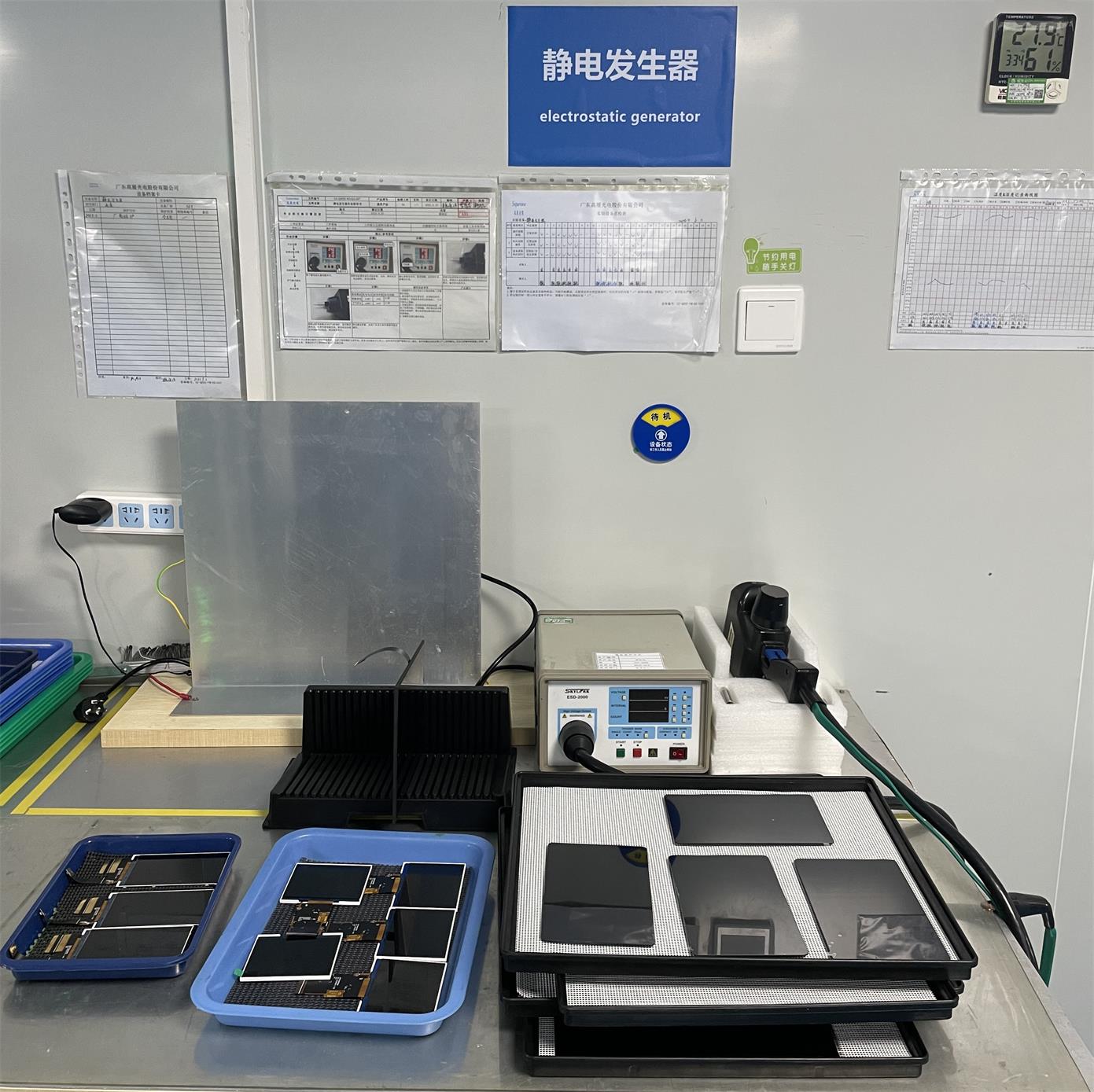

- ESD (Electrostatic Discharge) Test conditions: C=150pF, R=330Ω, 5 Point / Panel Surface Contact discharge: ± 8kV for 5 times (Class B), and Air discharge: ± 15kV for 5 times (Class B).

- This test is in accordance with the following specifications: IEC61000-4-2 and GB/T17626.2.

- The test is conducted using an Electrostatic Discharge Generator.

- ESD (Electrostatic Discharge) Test conditions: C=150pF, R=330Ω, 5 Point / Panel Surface Contact discharge: ± 8kV for 5 times (Class B), and Air discharge: ± 15kV for 5 times (Class B).

- This test is in accordance with the following specifications: IEC61000-4-2 and GB/T17626.2.

- The test is conducted using an Electrostatic Discharge Generator.

- Mechanical Shock Test conditions: Half Sine Wave, 100G for 6msec, ± X, ± Y, ± Z for 3 times each direction.

- The product is powered off during this test.

- This test is in accordance with the following specifications: IEC 60068-2-27-2008 and GB/T 2423.5.

- The test is conducted using an Impact Testing Apparatus.

- Mechanical Shock Test conditions: Half Sine Wave, 100G for 6msec, ± X, ± Y, ± Z for 3 times each direction.

- The product is powered off during this test.

- This test is in accordance with the following specifications: IEC 60068-2-27-2008 and GB/T 2423.5.

- The test is conducted using an Impact Testing Apparatus.

- Vibration Test conditions: Frequency: 8-33.3 Hz, Total amplitude: 1.3mm, Acceleration: 29.4 m/s², sweep time: 15 minutes.

- The test is conducted for 2 hours each in the X and Z directions, and 4 hours in the Y direction, for a total of 8 hours.

- The product is non-operational during this test.

- This test is in accordance with the following specifications: IEC60068-2-6 and GB/T2423.10.

- The test is conducted using a Vibration Measurement Instrument.

- Vibration Test conditions: Frequency: 8-33.3 Hz, Total amplitude: 1.3mm, Acceleration: 29.4 m/s², sweep time: 15 minutes.

- The test is conducted for 2 hours each in the X and Z directions, and 4 hours in the Y direction, for a total of 8 hours.

- The product is non-operational during this test.

- This test is in accordance with the following specifications: IEC60068-2-6 and GB/T2423.10.

- The test is conducted using a Vibration Measurement Instrument.

- Salt Spray Test conditions: Test temperature: 35℃, specific gravity of brine solution: 1.020 ~ 1.040, PH: 6.5 ~ 7.2, sodium chloride content: 5%± 1%, and spray time of 24 hours.

- This test is in accordance with the following specifications: IEC60068-2-6 and GB/T2423.1.

- The test is conducted using a Salt Spraying Tester.

- Salt Spray Test conditions: Test temperature: 35℃, specific gravity of brine solution: 1.020 ~ 1.040, PH: 6.5 ~ 7.2, sodium chloride content: 5%± 1%, and spray time of 24 hours.

- This test is in accordance with the following specifications: IEC60068-2-6 and GB/T2423.1.

- The test is conducted using a Salt Spraying Tester.