OLED displays are reshaping the smart home experience — delivering deeper blacks, thinner form factors, and energy-efficient always-on interfaces that blend seamlessly with modern interiors. This in-depth guide helps product managers, engineers, and procurement teams choose the right OLED display for smart home devices. We cover device architecture, performance trade-offs, power & lifetime considerations, integration best practices, application case studies (thermostats, security, mirrors, appliances), and a practical selection checklist.

Table of Contents

- Definition & Scope

- How OLED Displays Work

- Advantages for Smart Home Devices

- Key Specifications to Evaluate

- Power, Lifetime & Burn-in

- Design & Integration Best Practices

- Smart Home Use Cases

- OLED vs Alternatives (LCD, QD-LED, MicroLED)

- Testing & Certification Considerations

- FAQ

- Selection Checklist & Next Steps

Definition & Scope

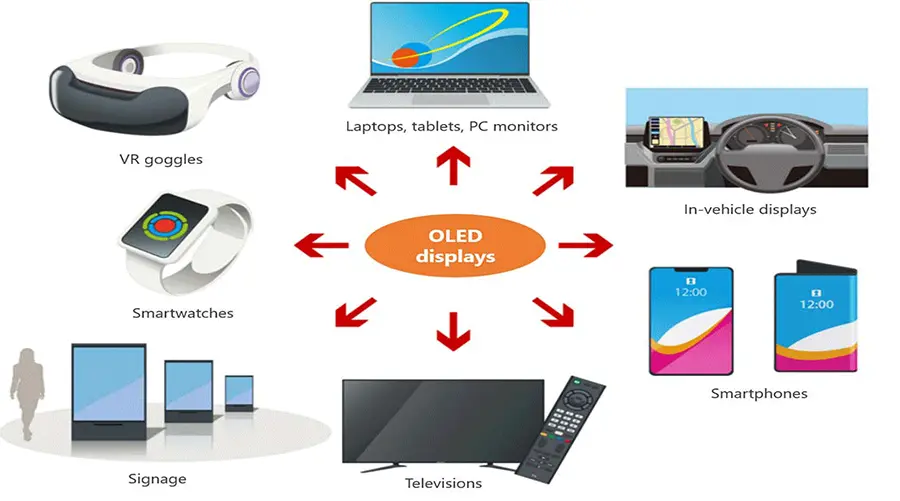

When we say “OLED display for smart home devices”, we mean packaged OLED modules (typically AMOLED) intended for embedded consumer electronics in home environments — thermostats, smart speakers with screens, security panels, connected appliances, smart mirrors, and wall-mounted dashboards. Compared to consumer televisions, these modules prioritize:

- compact mechanical integration, low-profile bezels, and touch integration

- low average power for always-on use and ambient information display (AoD)

- readability in a range of lighting conditions — indoor ambient to near-sunlight through glass

- cost and supply predictability for medium volumes (thousands to tens of thousands units)

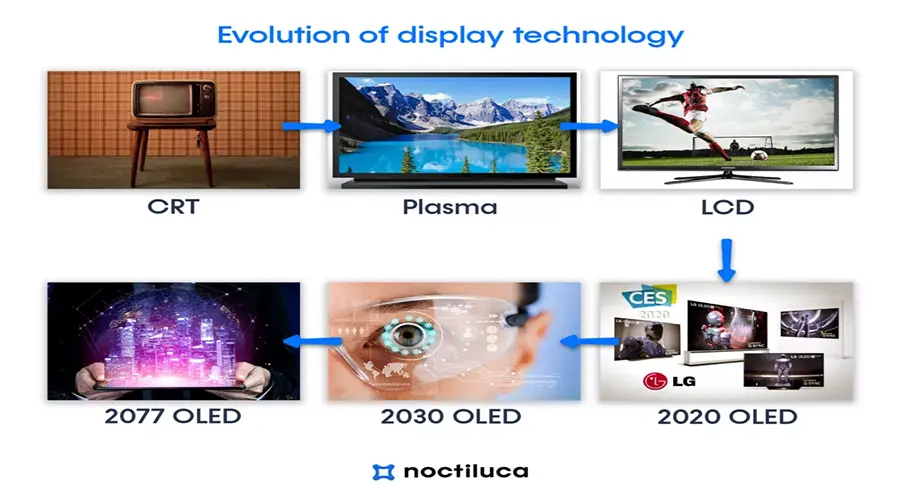

How OLED Displays Work (brief technical primer)

Emissive pixels and active matrix

OLED panels are emissive: each pixel contains organic materials that emit light when driven. Most smart home modules use AMOLED (Active-Matrix OLED) with a TFT backplane (LTPS / LTPO / IGZO). The active matrix provides per-pixel driving and a storage capacitor, enabling crisp graphics, high refresh rates, and low motion blur when needed.

Subpixel arrangements & color management

OEMs may choose RGB stripe, PenTile, or alternative subpixel patterns depending on lifetime and PPI tradeoffs. Software rendering and hardware color management (3D LUTs) are used to meet ΔE targets and white-point specifications (typically D65 for consumer UIs).

Drive modes & dimming

OLEDs support analog current drive and PWM dimming. For smart home devices, a hybrid approach is common: analog drive for mid/high brightness, and high-frequency PWM for extreme low-level control to avoid perceptible flicker in human vision.

Advantages for Smart Home Devices

1. Superior visual quality & perceived value

True blacks and infinite contrast give OLED interfaces a premium look that communicates product quality to buyers. For living spaces and luxury appliances, OLED elevates perceived value and user satisfaction.

2. Ultra-thin and flexible form factors

OLED modules allow ultra-slim bezels, curved edges, and flexible substrates for curved smart mirrors and thin control panels that integrate seamlessly into cabinetry or walls.

3. Energy advantage for ambient UIs

Many smart home interfaces are dark by default (clocks, notifications). OLED’s per-pixel emission means black pixels draw no current, translating to measurable energy savings vs. transmissive LCD backlights over a product lifecycle.

4. High contrast improves glanceability

Smart home interactions are often glance-based. High contrast and wide viewing angles ensure information is readable from different positions in the room and under various lighting conditions.

5. Faster response and touch feel

OLED pixel switching is fast; combined with low-latency touch controllers, the interface feels more responsive — particularly important for gesture interactions and touch-based smart appliances.

Key Specifications to Evaluate

When evaluating modules, require vendors to provide measurable specs (not just marketing numbers). Key items include:

- Active area & mechanical drawing — exact cutout and mounting tolerances

- Resolution & pixel density (PPI) — for text clarity and icon fidelity

- Peak / sustained luminance (nits) — spot HDR vs full-screen APL limits

- Color gamut & ΔE — factory calibration report and tolerances

- Viewing angle / contrast ratio — measured at defined angles

- Operating / storage temperature — especially if device lives near ovens, windows, or exterior doors

- Touch type & interface — projected capacitive, PCAP on-cell/under-panel; connector definition

- Interface protocols — MIPI DSI, LVDS, eDP, SPI, plus control channels (I2C for touch / EDID)

- MTBF / luminance lifetime (T80/T90) — measured under defined APL (e.g., 200 nits APL=20%)

- EMC / safety certifications — required for consumer electrical compliance

Power, Lifetime & Burn-in

Power modeling for smart home UI

Estimate average power by APL (average picture level). For OLED, power ≈ Σ(pixel_luminance × area × efficiency). Dark themes dramatically reduce consumption. If your device is expected to display static white content (e.g., setting pages), that will increase average power.

Lifetime metrics — T80/T90 explained

Vendors normally specify T80/T90 (time to 80%/90% of initial luminance) at a defined test condition (e.g., 200 nits APL at 25°C). Compare vendor measurement conditions carefully — mismatched test conditions distort lifetime comparisons.

Burn-in risk & mitigation

Prolonged static content can produce differential aging. For smart home products, adopt multi-layer mitigation:

- UI design: avoid permanent bright logos; prefer dark mode for persistent elements

- Firmware: pixel shift, temporary inversion, and scheduled “rest” screens

- Hardware: lower operating luminance, thermal management to avoid local hotspots

- Factory: compensate per-panel with LUTs and lifetime drift tables

Design & Integration Best Practices

Mechanical integration & thin-profile mounting

Provide exact bezel and cutout drawings. For wall-mounted hubs or mirrors, consider flush mounting with optical bonding to minimize reflection and enable cleaning. Use gasketed seals for environments with humidity (bathrooms, kitchens).

Thermal design

Even though OLEDs are efficient for dark content, high APL or long video playback creates thermal load. Include thermal paths, metal backplates, or phase-change pads for heat spreading. Validate under worst-case ambient temperatures (near ovens, under sunlight).

Touch and sensor co-design

Touch stack (on-cell vs add-on) affects optical clarity, cost, and thickness. For voice-hub displays, ensure proximity sensors and microphones are positioned to avoid acoustic interference with touch/optical layers.

UI & firmware strategies

Build UI guidelines for longevity: dark default theme, transient high-brightness states, and scheduled low-activity modes. Implement OTA updates that allow future burn-in mitigation algorithms to be deployed.

Smart Home Use Cases & Practical Examples

Smart thermostat

Thermostats benefit from OLED’s clarity for graphs and energy analytics. Example: a 3.5–5.0″ AMOLED module with 300–600 nits peak, touch, and proximity wake fits perfectly into wall-mounted thermostats that provide glanceable information and occasional deep interaction.

Voice assistant hub with screen

For hubs, the OLED display must balance always-on ambient info with momentary bright notifications. Use LTPO panels where available for variable refresh to save power in static scenes while enabling high frame rates for animation.

Smart mirror & bathroom hub

Transparent OLED or low-reflective OLED bonded behind mirror glass creates a seamless smart mirror. Prioritize anti-fog coatings and humidity-rated seals for this environment.

Security panel & camera dashboard

Security UIs require multi-camera thumbnails and near-real-time video. OLED modules with high color fidelity and low latency are advantageous, but you must manage continuous bright content and consider burn-in mitigation for persistent overlays.

OLED vs Alternatives (LCD, QD-LED, MicroLED)

| Metric | OLED | High-end LCD/QD-LED | MicroLED |

|---|---|---|---|

| Contrast / Blacks | True blacks, excellent | Good with local dimming, but backlight bleed | True blacks, excellent |

| Peak brightness (full screen) | Moderate; limited by thermal & lifetime | High (with strong backlight) | Very high |

| Power (dark UI) | Low | Higher (backlight on) | Variable; efficient at high nits |

| Thin / flexible integration | Excellent | Thicker, rigid | Rigid (until advanced processes) |

| Burn-in risk | Present, must mitigate | Low | Minimal |

| Cost (consumer scale) | Mainstream | Lower for basic modules | High (emerging) |

Testing, Certification & Compliance

For consumer devices, ensure modules and finished products pass regional safety and EMC tests (UL, CE, FCC). For kitchen/bath products, consider ingress protection (IP54/IP65) and surface durability standards. Request vendor test reports for:

- Thermal cycling and operational life (T80/T90 data)

- Moisture and ingress testing

- EMC and radiated emissions tests

- Touch durability and abrasion resistance

- Photobiological safety (blue light hazard) if high sustained brightness is used

FAQ — OLED Display for Smart Home Devices

1. Are OLED displays suitable for always-on smart home widgets?

Yes — with proper UI design (dark themes), pixel-shift, and duty cycling. Choose panels with proven lifetime metrics and implement firmware mitigation.

2. How much power can I save using OLED?

Savings depend on UI APL. For predominantly dark UIs, power reduction versus LCD can be 20–60% in display subsystem power. Run APL simulations using expected content for accurate estimates.

3. What about sunlight readability near windows?

Choose higher peak luminance options (600–1000 nits) and anti-reflective coatings. For direct outdoor sun, consider MicroLED or high-brightness LCD alternatives.

4. How to specify lifetime for procurement?

Request T80/T90 lifetime at a specified APL and ambient temperature, and ask for per-panel compensation LUTs and warranty terms aligned with expected duty cycles.

5. Can I retrofit OLED into an existing product that used LCD?

Often yes, but check mechanical depth, connector compatibility, touch stack differences, and thermal management. A simple PCB and firmware update may be insufficient — do a feasibility prototype first.

Selection Checklist & Next Steps

Use this short checklist when preparing an RFQ or technical evaluation:

- Specify exact mechanical dimensions, touch type, and connector pinout.

- State typical UI APL, peak nits required, and duty cycle (hours/day).

- Request T80/T90 lifetime data under your duty cycle and operating temperature.

- Ask for factory color calibration reports and ΔE tolerances.

- Confirm burn-in mitigation features (pixel shift, logo dimming) and firmware options.

- Require EMC, safety, and environmental test reports matching your target markets.

- Order engineering samples and run a 30–90 day pilot test in real usage conditions.

Share target size, expected UI content (APL), operating temperature, and annual volume. We will recommend suitable panels, integration notes, and a vendor short-list for prototyping.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.