An in-depth analysis of the engineering breakthroughs powering the next generation of consumer electronics.

Table of Contents

- 1. Introduction: The Shift to Flexible Forms

- 2. The Mechanics of the Fold: Hinge Evolution

- 3. Material Science: CPI vs. Ultra-Thin Glass (UTG)

- 4. Solving the "Crease" Conundrum

- 5. Rollable OLEDs: Beyond the Fold

- 6. The Automotive Revolution: Flexible Cockpits

- 7. Durability & Testing Standards

- 8. Market Outlook & Future Trends

- 9. Frequently Asked Questions (FAQ)

1. Introduction: The Shift to Flexible Forms

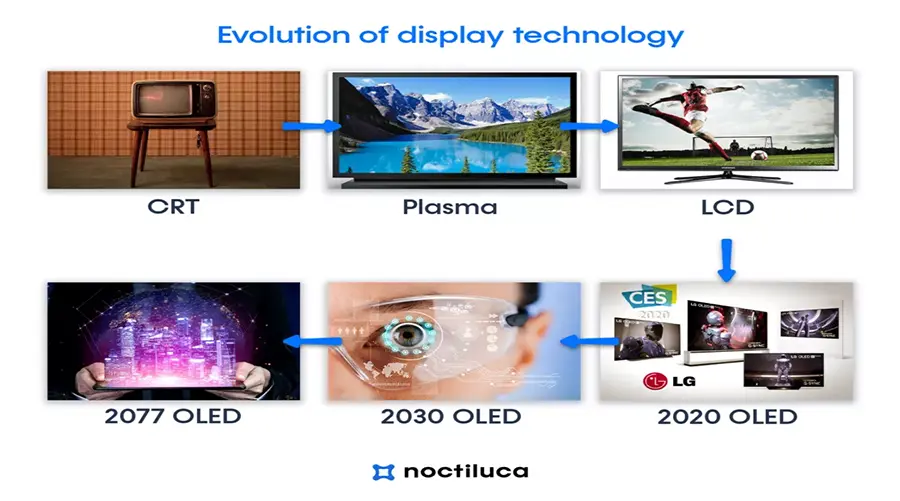

For over a decade, the "black rectangle" has dominated consumer electronics. Smartphones, tablets, and televisions have been defined by rigid glass substrates that dictate the form factor of the device. However, we are currently witnessing a paradigm shift in display technology that is as significant as the transition from monochrome to color.

Organic Light-Emitting Diode (OLED) technology has always held the promise of flexibility. Unlike Liquid Crystal Displays (LCDs), which require a backlight unit, OLEDs are self-emissive. This means the pixels themselves generate light, allowing the display structure to be incredibly thin and, theoretically, flexible. Today, that theory has become reality.

The market has moved past the "early adopter" phase where fragility was accepted as the price of innovation. We are now in the era of durability, where foldable and rollable devices are expected to perform as reliably as their rigid counterparts. This article explores the deep engineering challenges that have been overcome to bring us here.

2. The Mechanics of the Fold: Hinge Evolution

While the screen gets the glory, the hinge is the unsung hero of foldable devices. The hinge is not merely a door pivot; it is a complex mechanical watch-like system consisting of hundreds of interlocking parts designed to manage stress, reject dust, and maintain friction.

The "U-Shape" vs. The "Waterdrop"

Early foldables utilized a simple U-shaped fold. While functional, this design required a significant gap between the two halves of the phone when closed (resembling a wedge). This gap was a magnet for pocket lint and debris, which could damage the soft inner screen.

The industry standard has now shifted to the "Waterdrop" or "Dumbbell" Hinge. In this design, the screen retracts slightly into the hinge cavity when the device is closed, forming a teardrop shape with a larger radius. This achieves two critical goals:

- Zero-Gap Closure: The device can fold completely flat, sealing out dust.

- Reduced Stress: By increasing the bend radius internally, the stress on the OLED panel is distributed more evenly, reducing the severity of the crease.

3. Material Science: CPI vs. Ultra-Thin Glass (UTG)

The cover window—the part of the screen you actually touch—has undergone a radical transformation. The primary challenge is a paradox: the material must be hard enough to resist fingernail scratches but flexible enough to bend 200,000 times without snapping.

The Era of Plastic (CPI)

First-generation foldables used Colorless Polyimide (CPI). While flexible, CPI feels like plastic to the touch. It has a high friction coefficient (making swiping feel "sticky") and is prone to permanent deformation and scratches from everyday objects.

The Revolution of UTG

Ultra-Thin Glass (UTG) is the current gold standard. Produced by companies like Schott and Corning, UTG is processed to a thickness of roughly 30 to 50 micrometers—thinner than a human hair. At this thickness, glass loses its rigidity and becomes pliable.

4. Solving the "Crease" Conundrum

The "crease"—the visible groove running down the center of a foldable screen—has been the biggest consumer complaint. While physics dictates that any material folded repeatedly will eventually show signs of stress, engineering is minimizing its visibility.

Current "Zero-Crease" technologies employ a multi-faceted approach:

- Floating Support Plates: Underneath the display panel, manufacturers are installing support plates (often made of carbon fiber or stainless steel) that shift position. When the device opens, these plates push upwards against the fold area, physically ironing out the dip.

- Optical Adhesives: Specialized Optically Clear Adhesives (OCA) are used to bond the display layers. These adhesives are designed to have a refractive index that masks the distortion of light caused by the uneven surface of the crease.

5. Rollable OLEDs: Beyond the Fold

If foldables are the present, rollables (or slidables) are the immediate future. A rollable device solves the two main issues of foldables: the thickness (since it doesn't fold on itself) and the crease (since the screen curves gently rather than folding sharply).

How It Works

In a rollable smartphone, a motorized mechanism extends the chassis. The "extra" screen is stored rolled up inside the body of the phone, similar to a scroll. When activated, the screen unspools to transform a 6.5-inch phone into a 7.4-inch mini-tablet.

The Engineering Challenge: A rolled-out screen is naturally flimsy. To solve this, engineers use a "caterpillar track" design—a series of interlocking slats that unroll behind the screen to provide a rigid backing when extended, but become flexible when retracted.

6. The Automotive Revolution: Flexible Cockpits

The automotive industry is rapidly adopting flexible OLEDs to redefine vehicle interiors. We are moving away from flat, rectangular screens glued to dashboards towards "pillar-to-pillar" displays that curve with the interior design.

Tandem OLED Structures

Cars present a harsh environment for displays: extreme heat, freezing cold, and constant sunlight. To combat this, automotive OLEDs use a "Two-Stack Tandem" structure. This involves stacking two organic light-emitting layers on top of each other.

- Brightness: It delivers twice the brightness of a standard OLED, essential for visibility in daylight.

- Longevity: By sharing the load between two layers, the stress on the organic materials is reduced, quadrupling the lifespan of the display—a critical requirement for cars meant to last 10+ years.

7. Durability & Testing Standards

Durability is no longer a guessing game; it is a quantified metric. Modern foldable devices undergo rigorous testing protocols before reaching the market.

- Folding Cycles: The standard benchmark is now 200,000 to 400,000 folds. This equates to opening the phone 100 times a day for 5 to 10 years.

- Ingress Protection (IPX8): Early foldables were vulnerable to water. Today, top-tier foldables feature IPX8 water resistance, meaning they can be submerged in freshwater, achieved through sealing individual components and using anti-corrosive nanocoatings on the hinge.

- Temperature Shock: Devices are tested in folding chambers at -20°C to ensure the UTG and adhesives do not become brittle and snap in cold weather.

8. Market Outlook & Future Trends

The trajectory for flexible OLEDs is exponential. As manufacturing yields improve and costs decrease, we will see this technology trickle down from flagship devices to mid-range electronics.

We expect to see "360-degree" foldables (screens that fold both inwards and outwards) and hybrid laptops (where the entire surface is a screen, with a virtual haptic keyboard) becoming commonplace. The distinction between hardware and software is vanishing; the device is becoming a blank canvas that adapts to the content, rather than the content adapting to the device.

9. Frequently Asked Questions (FAQ)

Do foldable phones still have a visible crease?

While the crease has not been completely eliminated, it has been significantly reduced in the latest generation of devices. Thanks to "waterdrop" hinges and tension-relief mechanisms, the crease is now often invisible when looking at the screen head-on and is barely palpable to the touch.

Is Ultra-Thin Glass (UTG) actually glass?

Yes, UTG is real glass. It is processed to be incredibly thin (around 30 microns), which gives it flexible properties. However, it is usually coated with a thin layer of plastic polymer for protection. This gives you the optical clarity of glass with the flexibility required for folding.

How long do foldable screens last?

Most modern foldable smartphones are rated for at least 200,000 folds. If you open your phone 50 times a day, this rating theoretically covers over 10 years of usage. The hinge mechanism is often the most durable part of the device.

What is the difference between Foldable and Rollable OLED?

A foldable OLED bends along a fixed axis (like a book), creating a crease. A rollable (or slidable) OLED unspools from an internal roller (like a scroll). Rollables generally avoid the deep crease issue and allow for variable screen sizes, but the mechanical complexity is higher.

Are flexible screens used in cars safe?

Yes. Automotive-grade OLEDs undergo much stricter testing than consumer electronics. They utilize "Tandem OLED" technology to ensure high brightness and longevity, and they are tested to withstand extreme temperature fluctuations and vibrations found in vehicles.

Can I use a regular screen protector on a foldable phone?

Generally, no. Foldable phones come with a factory-installed screen protector that is integral to the display's structural integrity. Removing it or applying a third-party rigid protector can damage the soft UTG layer or interfere with the closing mechanism.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.