Introduction

Active-Matrix Organic Light-Emitting Diode (AMOLED) technology represents one of the most transformative breakthroughs in the display industry. Distinguished from conventional liquid crystal displays (LCDs), AMOLEDs are self-emissive, meaning each pixel produces its own light without requiring an external backlight. This property allows AMOLEDs to achieve thinner form factors, higher contrast ratios, faster response times, and lower power consumption under many conditions. Over the past two decades, AMOLED has become the preferred display technology for premium smartphones, televisions, wearable devices, and an expanding range of industrial and automotive applications.

This comprehensive technical article—prepared by BROWNOPTO—is designed to fill critical knowledge gaps about AMOLED technology. It provides not only a detailed overview of the physical principles, material science, fabrication processes, and performance metrics, but also an analysis of reliability concerns, market drivers, and future directions. By combining academic research, industrial practice, and cutting-edge innovation, this article offers a 360-degree perspective on AMOLED technology for researchers, engineers, investors, and decision-makers.

Principles of AMOLED

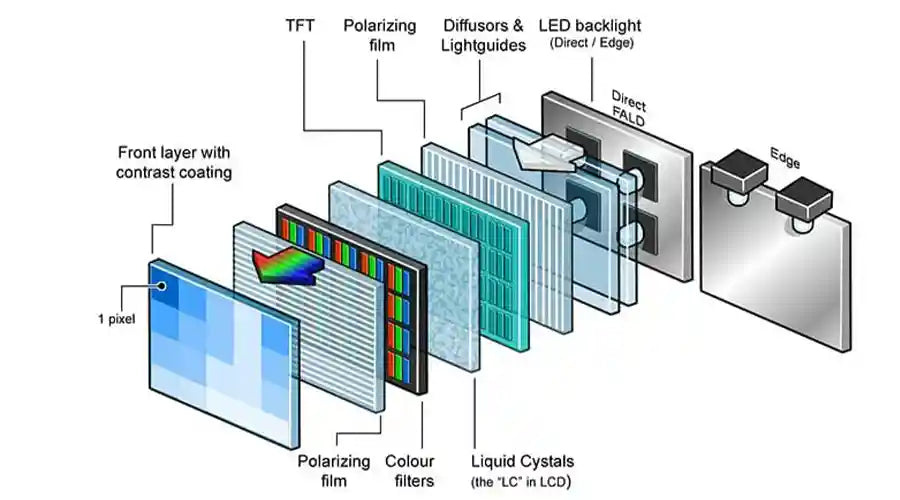

Fundamentals of Electroluminescence

The core principle behind AMOLED displays is electroluminescence in organic semiconductors. When a voltage is applied across an OLED device, electrons are injected from the cathode and holes from the anode into organic layers. These charge carriers recombine within the emissive layer, forming excitons that decay radiatively to emit photons. The emission spectrum depends on the molecular structure of the emissive material, allowing precise color tuning.

Compared with inorganic LEDs, organic molecules offer advantages such as flexible processing, tunable emission, and compatibility with large-area substrates. However, they are also prone to degradation, requiring careful material design and device engineering.

AMOLED Pixel Operation

AMOLED displays differ from passive matrix OLEDs (PMOLEDs) by integrating a thin-film transistor (TFT) backplane that actively drives each pixel. Each sub-pixel typically consists of two or more TFTs and a storage capacitor, forming a circuit that controls current flow precisely. The current-based driving mechanism allows AMOLED to achieve higher resolution, larger screen sizes, and improved refresh rates.

The active matrix ensures uniformity and enables compensation circuits to correct for material and device degradation, an essential feature for commercial-grade displays. Without this active matrix, OLED displays would suffer from limited scalability and poor image stability.

Exciton Formation and Recombination

Exciton dynamics govern the efficiency of OLED devices. Electrons and holes injected into the emissive layer can form singlet or triplet excitons, depending on their spin states. Singlets decay radiatively through fluorescence, while triplets may decay non-radiatively unless special mechanisms are used. Phosphorescent materials exploit heavy-metal complexes to harvest triplet excitons, dramatically improving efficiency. More recently, thermally activated delayed fluorescence (TADF) materials have emerged, enabling triplet harvesting without heavy metals, thereby lowering cost and environmental impact.

Materials and Device Structures

Anode and Cathode Materials

The anode is usually transparent and conductive, with indium tin oxide (ITO) being the most common choice. However, ITO suffers from brittleness and limited indium availability. Alternatives such as graphene, silver nanowires, and conductive polymers are being investigated for flexible AMOLEDs. The cathode typically consists of low-work-function metals like aluminum, magnesium, or calcium, often combined with thin interfacial layers to improve injection efficiency.

Organic Layers

AMOLED stacks are composed of multiple organic layers, each serving a distinct function:

- Hole Injection Layer (HIL): Facilitates hole injection from the anode.

- Hole Transport Layer (HTL): Conducts holes toward the emissive layer.

- Emissive Layer (EML): Contains doped host–guest systems responsible for light emission.

- Electron Transport Layer (ETL): Transports electrons from the cathode.

- Electron Injection Layer (EIL): Improves electron injection efficiency.

Host–Guest Systems

In emissive layers, host–guest systems are commonly used. A wide-bandgap host material transports carriers efficiently, while a dopant guest material emits light with high efficiency. The host confines excitons and transfers energy to the dopant. This strategy prevents concentration quenching and improves color purity.

Encapsulation

Organic materials are highly sensitive to moisture and oxygen. To protect AMOLED panels, encapsulation techniques are essential. Traditional methods use glass caps, while flexible AMOLEDs require thin-film encapsulation (TFE) based on alternating inorganic/organic barrier layers. BROWNOPTO has developed advanced encapsulation processes that extend lifetime without compromising flexibility.

Driving Technologies

LTPS and Oxide TFT Backplanes

AMOLED driving relies on thin-film transistors (TFTs) to regulate current. Low-temperature polycrystalline silicon (LTPS) TFTs offer high mobility and small feature sizes, making them suitable for high-resolution displays. However, LTPS has limitations in large-area uniformity. Oxide TFTs, based on indium gallium zinc oxide (IGZO), provide superior uniformity, lower leakage currents, and easier scalability to large panels. Many display manufacturers now combine LTPS for driving circuits and IGZO for switching transistors.

Compensation Circuits

Compensation circuits are vital to address threshold voltage shifts and mobility variations in TFTs, as well as degradation of OLED materials. Various compensation schemes exist, including current feedback, threshold sensing, and mobility adaptation. BROWNOPTO has pioneered novel circuit architectures that minimize non-uniformity and extend panel lifetimes.

Refresh Rates and Power Optimization

AMOLED displays support high refresh rates, essential for gaming and virtual reality applications. However, higher refresh rates increase power consumption. Adaptive refresh technology dynamically adjusts the frame rate according to content, reducing energy use without compromising visual performance.

Fabrication Processes

Vacuum Thermal Evaporation

Vacuum thermal evaporation (VTE) through fine metal masks (FMM) remains the dominant method for depositing organic layers in AMOLED manufacturing. This process allows precise control over film thickness and patterning. However, challenges include mask alignment, sagging, and scalability. Material utilization efficiency is also relatively low, raising costs.

Solution-Based Processing

Inkjet printing and solution processing are being explored as cost-effective alternatives. These techniques promise higher material utilization, simplified patterning, and compatibility with large substrates. However, challenges such as solvent interactions, film uniformity, and defect control remain.

Encapsulation and Sealing

Encapsulation is crucial for long-term reliability. Thin-film encapsulation (TFE) techniques employ multilayer barriers to protect organic layers from moisture ingress. Atomic layer deposition (ALD) is often combined with organic layers to achieve ultra-low permeability.

Performance Characteristics

Color Gamut and Brightness

AMOLED panels deliver exceptional color performance. By carefully tuning emissive materials, manufacturers achieve wide gamuts that exceed sRGB and even DCI-P3 standards. Emerging materials, including quantum-dot OLED hybrids, extend gamut coverage even further. Brightness levels now exceed 1500 nits in premium smartphones, ensuring visibility in outdoor environments.

Contrast and Black Levels

Since AMOLED pixels are self-emissive, black levels are achieved by turning off pixels entirely. This results in near-infinite contrast ratios, offering superior visual experiences for HDR content compared with LCDs.

Response Times and Refresh Rates

OLED materials inherently switch faster than liquid crystals, yielding microsecond response times. This eliminates motion blur, making AMOLED suitable for high-speed video and immersive VR displays.

Power Efficiency

Power efficiency in AMOLED depends strongly on image content. Dark user interfaces save energy because fewer pixels emit light. Manufacturers now integrate adaptive brightness and subpixel rendering algorithms to further enhance efficiency. BROWNOPTO has invested in advanced drive algorithms to minimize energy use across applications.

Applications

AMOLED technology is widely applied in smartphones, televisions, smartwatches, and tablets. Its flexibility has enabled new product categories such as foldable smartphones and rollable displays. Automotive applications are expanding rapidly, with AMOLED serving as instrument panels, heads-up displays, and transparent infotainment screens. Medical imaging, industrial visualization, and augmented reality are emerging fields where AMOLED’s superior contrast and response speed provide decisive advantages.

Challenges and Reliability

Despite its advantages, AMOLED technology faces challenges. The most critical is the limited lifetime of blue emissive materials, which degrade faster than red and green. This imbalance causes color shifts over time. Other issues include burn-in, where static content leaves permanent ghost images, and susceptibility to moisture and oxygen. Manufacturing challenges include yield losses, high costs of fine metal masks, and limitations in scaling production to very large sizes.

Market Outlook and Competing Technologies

AMOLED has become dominant in premium smartphones, but it faces competition from emerging display technologies. MicroLED promises higher brightness and longer lifetimes, though fabrication complexity and cost remain hurdles. Quantum-dot displays (QLED) provide wide color gamuts but still require backlights, lacking the thinness and flexibility of AMOLED. LCD technology continues to improve with mini-LED backlights, offering cost advantages in larger panels.

Market forecasts indicate AMOLED shipments will continue growing, driven by foldable devices, automotive integration, and new wearables. BROWNOPTO has positioned itself as a technology leader, providing tailored AMOLED solutions for industrial and medical sectors, where performance and reliability outweigh cost considerations.

Future Prospects

Future directions of AMOLED include fully flexible and stretchable panels, transparent displays for architectural integration, and ultra-high-resolution panels exceeding 2000 pixels per inch for VR/AR applications. Key material challenges such as extending blue emitter lifetime, reducing manufacturing cost, and developing eco-friendly alternatives will guide innovation. Hybrid architectures that combine OLED with microLED or quantum-dot elements may offer new paradigms for performance and efficiency.

FAQ

Q1: What is an AMOLED display module?

A1: A self-emissive subsystem: TFT backplane, OLED stack, optics/encapsulation, DDIC/timing, interface.

Q2: How does LTPO save power?

A2: Wide-range VRR (down to 1–10 Hz) reduces both motion and idle power.

Q3: Is high-frequency PWM necessary?

A3: Helps flicker-sensitive users in low light; ≥960 Hz or hybrid/DC-like modes recommended.

Q4: How to minimize burn-in risk?

A4: To reduce burn-in on AMOLED screens: Lower brightness. Use short screen timeout. Avoid showing the same image too long. Turn off the screen when not in use.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.