Executive Summary

This technical brief examines AMOLED (Active Matrix Organic Light-Emitting Diode) technology with a focus on modules sized from 1.38 inches to 8.0 inches. We cover the physical structure, driving schemes, measurable performance metrics, common failure modes, and best practices for system integration. Brownopto offers a portfolio of customizable AMOLED modules across these sizes, designed for wearables, automotive clusters, industrial HMIs, and specialized medical devices.

Note: This article is aimed at product managers, hardware engineers, and procurement teams evaluating AMOLED modules for integration. For a direct sample or technical datasheet, see the product links in the Brownopto AMOLED Modules section below.

What is AMOLED?

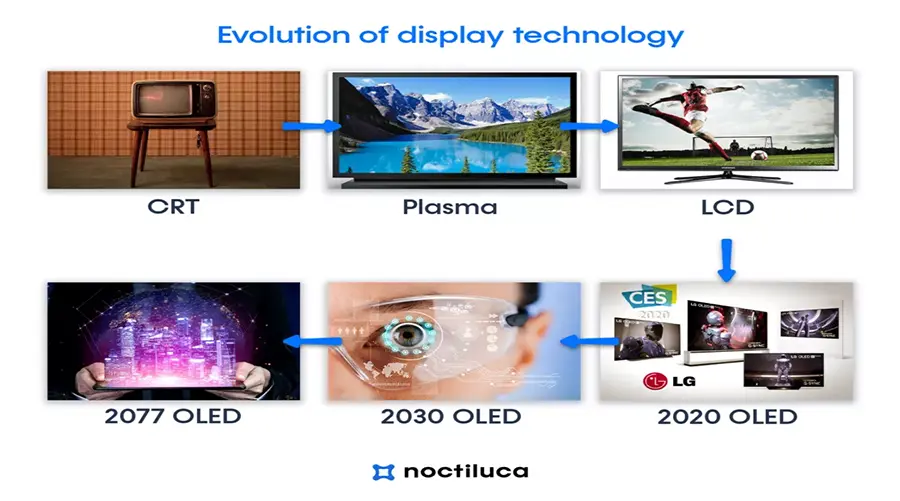

AMOLED stands for Active Matrix Organic Light-Emitting Diode. It is a self-emissive display technology that integrates an organic emissive layer with an active matrix backplane (typically thin-film transistors, TFTs) to control pixels individually. Unlike transmissive LCDs that require a backlight and color filters, AMOLED pixels emit light directly, enabling deeper blacks, higher contrast ratios, and thinner module stacks.

Key structural components

- TFT Backplane: Usually LTPS (Low-Temperature Poly-Si) or oxide TFTs that provide the active matrix addressing and current control.

- Organic Emissive Stack: Hole injection/transport layers, emissive dopants, electron transport/injection layers — designed for color, efficiency and lifetime.

- Encapsulation & Barrier: Thin-film encapsulation (TFE) or glass + barrier solutions to prevent moisture/oxygen ingress.

- Driver ICs & Flex Cables: Integrated driver ICs and FPC/FFC connectors tuned to the module's interface (RGB, MIPI DSI, SPI, MCU parallel, etc.).

How AMOLED Works (Technical Overview)

Each AMOLED pixel contains red, green and blue sub-pixels that are current-driven. The active matrix architecture uses TFTs to sustain a constant current through the organic diode for the duration of a frame. Frame rates, PWM dimming strategies, and gamma correction algorithms influence both perceived quality and power consumption.

Driving methods

Two common driving strategies are used:

- Voltage-driven (passive): Rare for high-resolution displays due to lack of per-pixel control.

- Current-driven active matrix: Preferred for stable brightness control; typically implemented with LTPS TFT backplanes.

Color & calibration

AMOLED color is a combination of material emission peak wavelengths and color filter/stack engineering. Precise color management requires factory calibration (CIE1931 or CIE1976 targets), plus onboard gamma lookup tables or software-based color correction during system integration.

Key Advantages

Superior contrast & black level

Because pixels can be completely switched off, AMOLED delivers near-infinite contrast in dark scenes — critical for automotive HUDs, medical imaging displays, and premium consumer devices.

Thin profiles & flexibility

Without the need for a backlight, AMOLED modules are significantly thinner and can be made flexible in specialized designs. This reduces BOM thickness and enables novel industrial or wearable form factors.

Faster response times

Pixel response is measured in micro- to low-millisecond ranges, reducing motion blur for animations and rapidly updating UX elements.

Power efficiency for dark UIs

AMOLED's energy model privileges dark user interfaces — applications that render significant black regions will observe reduced average current draw compared to transmissive displays.

Performance Metrics & Measurement

When qualifying AMOLED modules, engineers should measure and document:

- Luminance (cd/m²): Peak and typical luminance at specified drive currents and voltage.

- Color coordinates: CIE 1931 x,y or CIE 1976 u',v' at white point(s).

- Contrast ratio: Measured as the ratio between peak white and black (dark) luminance.

- Lifetime (T50 / T70): Time to 50%/70% initial luminance under defined stress conditions.

- Burn-in / Image Retention: Standardized testing for long-term static content resilience.

- Power consumption: Average draw for representative content and worst-case peak current.

- Spectroradiometer for spectral power distribution & color coordinates.

- Integrating sphere for precise luminance and flux measurements.

- Environmental chamber for lifetime and humidity testing.

Form Factors: 1.38–8.0" Modules

Brownopto supports modular AMOLED products spanning small to medium diagonal sizes. Below is a concise breakdown of typical uses by size and key engineering considerations.

| Diagonal | Typical Use Cases | Design Considerations |

|---|---|---|

| 1.38" – 2.0" | Wearables, smart rings, compact sensors | Ultra-low power, high pixel density, sunlight readability, small FPC routing |

| 2.4" – 3.5" | Handheld devices, smart remotes, small control panels | Balanced brightness, touch integration, mechanical mounting |

| 3.5" – 5.0" | Industrial HMIs, medical handhelds | EMC shielding, robust connectors, optical bonding options |

| 5.5" – 8.0" | Automotive clusters, infotainment adjuncts | High brightness, anti-reflective coatings, temperature resilience |

For each target diagonal, Brownopto can provide customization on resolution, interface (MIPI DSI / RGB / MCU), touch sensor integration (projected capacitive or resistive), and mechanical housings.

Primary Applications

Wearables & Health Devices

Small AMOLED modules offer superior readability and low standby power. For pulse oximeters and compact wearable displays, Brownopto's 1.38–2.0" modules are optimized for optical performance and efficient backplane driving.

Industrial HMI

AMOLED's contrast and viewing angle are advantageous in conditions where ambient lighting varies. Mid-size Brownopto modules offer IP-rated front assemblies for harsh environments.

Automotive Interfaces

High brightness and wide temperature range variants support automotive clusters and infotainment panels. Brownopto recommends anti-reflection coatings and adaptive brightness drivers for optimal safety and comfort.

Integration Guidelines for Engineers

Power & Thermal Management

AMOLED modules are current-driven; thus power supply design should include headroom for peak currents and efficient DC-DC regulation. Thermal dissipation paths must be considered — prolonged high luminance can accelerate material degradation.

EMI & Signal Integrity

When using high-speed interfaces (MIPI DSI), ensure controlled impedance routing and proper connector shielding. Use common-mode chokes and ESD protection to protect driver ICs during assembly and field use.

Touch & Optical Bonding

For high-visibility applications, optically bonding the touch panel to the AMOLED surface reduces internal reflections and increases contrast. Select adhesives with stable refractive index across temperature ranges to avoid visual artifacts.

Firmware & Gamma Calibration

Implement LUT-based gamma correction and dynamic current compensation to maintain color stability over lifetime. Brownopto can provide calibration vectors and reference profiles for rapid integration.

Brownopto AMOLED Modules (Product Links)

Brownopto manufactures and supplies customizable AMOLED modules covering diagonals from 1.38" to 8.0". Typical product options include various resolutions, interface selections and optional touch integration.

Explore AMOLED Modules Collection

Sample datasheet request

If you require sample units or a customized quote (mechanical drawing, interface pinout, custom FPC length), contact Brownopto sales with your target diagonal, interface type, operating temperature range, and expected annual volume. Typical lead time for low-volume customization is provided upon request.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.