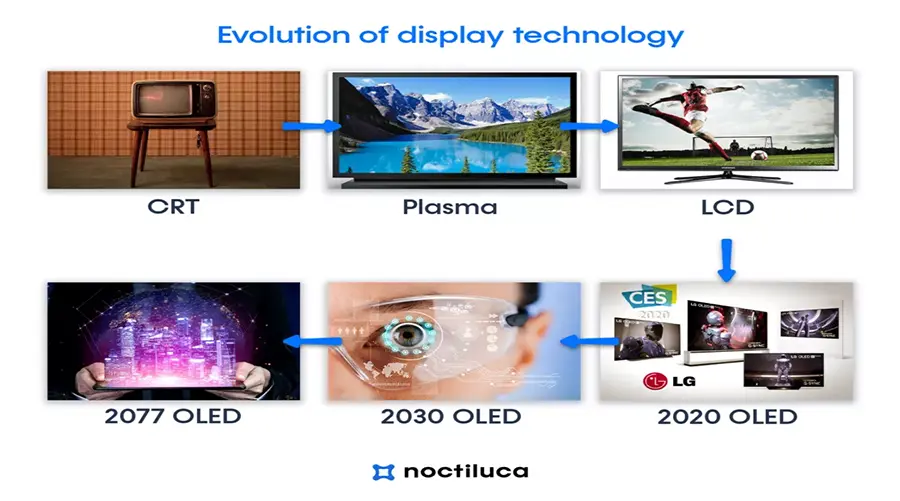

Introduction — What Is an OLED Display and Why It Matters

An OLED display (Organic Light-Emitting Diode) is a self-emitting display technology where each pixel produces light through electroluminescence in organic semiconductor materials. Because OLED pixels are self-luminous, they do not need a backlight, which enables thinner displays, greater contrast (true blacks), wider viewing angles, faster response times, and the potential for flexible or transparent form factors.

OLED technology has become the premium choice across mobile phones, wearable devices, high-end televisions and emerging AR/VR systems. This guide dives into the technical details you need to evaluate, specify, and integrate OLED modules into commercial products.

OLED Display Working Principle — How OLED Works at the Pixel Level

Electroluminescence and Organic Semiconductors

At the heart of every OLED pixel are organic semiconductors that emit light when electrically excited. The canonical OLED stack includes:

Substrate: glass, or flexible film (polyimide) for foldable devices;

Anode: typically indium tin oxide (ITO) to inject holes;

Hole transport layer (HTL) and electron transport layer (ETL) to facilitate carrier movement;

Emissive layer (EML): organic molecules (fluorescent, phosphorescent or TADF) where radiative recombination occurs;

Cathode: a low-work-function metal to inject electrons;

Encapsulation: barrier layers to protect organics from moisture and oxygen.

When a forward bias is applied, holes from the anode and electrons from the cathode meet in the emissive layer, forming excitons that decay radiatively and emit photons. The color of emitted light depends on the emissive molecule's energy gap.

Subpixel Architectures — RGB, White-OLED, and Color Conversion

Manufacturers implement color using different approaches:

RGB subpixel patterning: separate red, green, and blue emitters patterned at pixel level — high color efficiency but more complex patterning.

White OLED (WOLED) + color filters: use white emission and filter it into RGB components — simplifies emitter selection but introduces filter losses.

Blue OLED + color conversion (e.g., QD-OLED): uses blue emissive layer and quantum dots to convert portions of blue light into red/green, potentially improving lifetime and color purity.

Tandem OLEDs and Stacked Emitters

Tandem OLEDs stack multiple emissive units separated by charge generation layers to increase brightness and improve lifetime per stack. Tandem structures are attractive for HDR TVs and automotive displays where high peak luminance is essential without dramatically accelerating degradation.

Types of OLED Displays — AMOLED, PMOLED, microOLED and Flexible OLED

AMOLED: Active-Matrix OLED Display

AMOLED panels incorporate a TFT backplane (LTPS, IGZO, LTPO) and per-pixel driving transistors. This allows precise current control, high pixel densities, fast refresh rates and large display sizes. AMOLED is the dominant architecture in smartphones, tablets and high-performance monitors.

PMOLED: Passive-Matrix OLED Display

PMOLED uses a simpler row/column driving scheme and is suited for small displays (status panels, simple wearable screens). PMOLED is low-cost but limited in achievable resolution and panel size due to multiplexing constraints.

Flexible and Foldable OLED Displays

Flexible OLEDs use polymer substrates and thin-film encapsulation to enable bending and folding. These panels require special mechanical design (bend radius, hinge stress limits) and robust barrier layers to protect against moisture ingress.

MicroOLED Displays for Near-Eye Systems

MicroOLEDs are ultra-high pixel density displays used in AR/VR optics where very high pixels-per-degree (PPD) are needed. Microdisplays often involve different fabrication flows and are optimized for brightness, efficiency and low latency.

Materials, Deposition and Manufacturing Considerations for OLED Display Panels

Emissive Materials — Fluorescent, Phosphorescent, TADF and Quantum Dots

Emissive materials determine efficiency and lifetime. Fluorescent emitters historically had lower internal quantum efficiency (IQE), while phosphorescent materials can harvest triplet excitons to approach higher IQE—making green and red phosphorescent emitters common. Blue remains challenging; TADF and quantum-dot color-conversion approaches are active R&D areas to improve blue emitter stability.

Deposition Methods: Vacuum Thermal Evaporation (VTE) and Printing

VTE with fine metal masks (FMM) is widely used for small-molecule OLEDs and precise RGB patterning. For large-area or lower-cost manufacturing, inkjet printing and other solution processes are being developed but require tight control of film uniformity and solvent interactions.

Encapsulation and Barrier Technologies

Encapsulation is critical because organic layers are sensitive to moisture/oxygen. Rigid glass packages use glass lids and desiccants; flexible panels use thin-film encapsulation (alternating inorganic/organic layers) to provide barrier performance while remaining bendable.

Backplane Options: LTPS, IGZO and LTPO

LTPS offers high electron mobility for very high PPI. IGZO backplanes provide low leakage for large panels. LTPO (a hybrid) allows dynamic refresh-rate control — useful in mobile devices to reduce power consumption by lowering refresh during static content.

Driving, Control and Calibration of OLED Display Modules

Analog Current Drive vs PWM and Multi-Mode Dimming

OLED pixels are typically current-driven. Constant current driving tends to preserve color consistency; PWM is sometimes used for dimming but can introduce flicker. Modern drivers combine analog and PWM strategies to achieve deep dimming without color shift or visible flicker.

Gamma, Color Profiles and Compensation Algorithms

Maintaining color accuracy requires color calibration (lookup tables), white point control, and ongoing compensation for pixel aging. System firmware should support factory calibration and field re-calibration routines. Dynamic compensation algorithms monitor cumulative pixel current (wear leveling) and periodically adjust drive currents to even out degradation.

High Refresh and Variable Refresh Rate Integration

OLEDs support very high refresh rates. With LTPO backplanes, displays can dynamically change refresh (e.g., 1Hz for static content, 120Hz for gaming) to save power. Careful firmware coordination is required to avoid artifacts during transitions.

Key Performance Metrics — How to Evaluate an OLED Display

Luminance, HDR Capability and Color Gamut

Look at peak (nit) and sustained luminance, color gamut coverage (sRGB, DCI-P3, Rec.2020), and HDR tone mapping support. For HDR, both peak luminance and local dimming / tone mapping behavior affect perceived image quality.

Contrast Ratio, Black Level and Viewing Angle

Because OLED pixels can be fully turned off, contrast ratio is effectively infinite in dark scenes—the primary benefit for cinematic content. Viewing-angle performance for OLEDs is typically excellent with minimal color shift.

Lifetime Metrics: LT95, LT50 and ΔE Color Shift

Lifetime is reported as LT95 or LT50 (time to 95% or 50% of initial luminance) at a specified luminance and temperature. Watch for vendor-provided color shift specifications (ΔE) across expected lifetimes.

Power Consumption — Content Dependency

Estimate energy consumption based on expected UI content. Dark-mode and adaptive UI strategies substantially reduce average power for OLED. For worst-case white screens, model the impact on battery life and thermal behavior.

Reliability and Failure Modes — Burn-In, Degradation and Environmental Sensitivities

Mechanism of Burn-In and Image Retention

Burn-in results from non-uniform aging of RGB subpixels when static content is displayed over extended periods. The result is a permanent or semi-permanent ghost image that becomes visible when the surrounding content changes.

Mitigation Techniques: UI, Firmware, and Material Engineering

Mitigation strategies include UI designs (avoid static logos), system-level features (pixel shift, screensavers, dimming), firmware compensation (age-equalization LUTs), and material improvements (more stable blue emitters, tandem structures). For mission-critical displays, consider hybrid solutions or frequent refresh of UI elements to avoid static high-contrast regions.

Environmental Durability: Moisture, Temperature and Mechanical Stress

OLEDs are vulnerable to moisture and oxygen; encapsulation is essential. Thermal management is also critical—high operating temperatures speed degradation. Flexible panels require mechanical testing for bend endurance and hinge design validation.

Testing and Quality Assurance for OLED Display Modules

Photometric and Colorimetric Measurements

Test for luminance uniformity, color uniformity (ΔE maps), spectral power distribution (SPD), and chromaticity coordinates. Use integrating spheres, spectroradiometers and imaging colorimeters to capture per-pixel and region-based metrics.

Environmental and Mechanical Stress Testing

Perform HAST (high-accelerated stress testing), thermal cycling, humidity tests, mechanical flex/bend endurance (for foldables), and vibration/shock testing to qualify modules for target applications.

Accelerated Aging and Burn-In Protocols

Run accelerated aging at elevated brightness and temperature to model long-term behavior (LT95/LT50). Image retention tests simulate common static UI elements and can validate firmware compensation approaches.

Electrical Safety, EMI and System Integration Checks

Ensure driver ICs, power delivery and connectors meet EMI/ESD standards. Validate display behavior across input voltage ranges and under transient events to ensure product robustness.

Design and Integration Guidance — Best Practices When Using OLED Displays

UI/UX Guidelines to Protect OLED Lifetime

Prefer dark themes, avoid static full-screen elements, and implement adaptive brightness. Provide options for users to reduce brightness and enable screen savers. Where possible, animate or shift persistent UI elements subtly to distribute wear.

Mechanical Design and Thermal Management

Design enclosures to manage heat, avoid hotspots near high-current drivers, and ensure hinge geometry respects the panel's minimum bend radius. For automotive use, ruggedize mounting and thermal pathways to handle wide ambient ranges.

Electrical Interface and Connector Robustness

Use industry-standard high-speed interfaces (MIPI DSI, eDP) and specify robust connector retention and shielding. Consider board-level protection for ESD and EMI to prevent system-level failures.

Firmware Strategies for Longevity

Implement wear-leveling algorithms, dynamic adjustment of white point, and factory calibration with achievable field re-calibration paths. Monitor cumulative pixel current as a metric for remaining useful life estimation.

Procurement Checklist — Specifying an OLED Display for Production

When sourcing OLED modules, include the following in your specification to minimize surprises during integration and scaling:

Panel Architecture: AMOLED, PMOLED, or microOLED; substrate type (glass or polyimide/PI); encapsulation method (thin-film or glass-lid).

Resolution & Pixel Density: Native resolution, pixel pitch, and target PPI at the intended viewing distance.

Brightness & Contrast: Peak and typical luminance (in cd/m²), HDR support, and measured contrast ratio (e.g., >1,000,000:1).

Color Performance: Target color gamut (e.g., sRGB, DCI-P3, Rec.2020), factory calibration process, and color accuracy (ΔE < 3).

Lifetime & Reliability: Projected lifetime (LT95/LT50 at specified luminance), color shift targets over time, and test conditions (temperature, duty cycle).

Power Consumption: Typical and peak power draw under representative UI workloads; compliance with system-level power budgets.

Mechanical Specifications: Overall thickness, dimensional tolerances, minimum bend radius (for flexible variants), and connector pinout/layout.

Qualification & Testing: Required reliability tests (e.g., HAST, thermal cycling, vibration, flex endurance) and pass/fail criteria.

Supply Chain & Compliance: Minimum order quantity (MOQ), lead times, IP protection (NDA), QA audit requirements, and supply chain transparency.

Sample Validation and Production Ramp

Request engineering samples and run them through your complete system-level test plan (photometry, thermal, vibration, lifecycle). Establish incoming quality checks and sample-based lot acceptance metrics before ramping to mass production.

Applications for OLED Displays — From Smartphones to AR/VR

Smartphones and Tablets: The Flagship Use Case

High-end handsets rely on OLED displays for color, contrast and thinness. Features like always-on display, high refresh rates and curved edges are enabled by OLED technology and drive premium user experiences.

Wearables and Smartwatches

Wearables benefit from OLED's high contrast and energy-efficiency in dark UI modes. Micro-OLED and PMOLED are widely used in small displays for fitness trackers and watches.

Televisions and Professional Monitors

OLED TVs provide cinematic contrast and are preferred for living-room viewing and color-critical professional editing. For professional monitors, OLED offers consistent color and fast response for video work.

Automotive Displays and Heads-Up Systems

Curved and flexible OLEDs integrate into dashboards and center stacks; high contrast and wide viewing angles improve readability in varied lighting. Transparent OLEDs and HUDs are emerging as advanced cockpit solutions.

AR/VR Near-Eye Microdisplays

AR/VR systems demand very high pixel density with low persistence — microOLED and microLED are prime candidates due to their PPI and responsiveness.

Future Trends — Tandem OLED, QD-OLED, microOLED and Beyond

Tandem OLED and High Peak Brightness

Tandem structures stack emissive units to raise absolute luminance while reducing per-stack stress, improving lifetime under high-brightness operation. Tandem is becoming common in TV and automotive displays that require high HDR performance.

QD-OLED and Color Conversion Techniques

Quantum-dot enhanced OLED uses blue emitters with quantum dot converters to produce high-quality red and green light—potentially offering better lifetime and gamut than traditional RGB patterned emitters.

MicroOLED and AR/VR Integration

MicroOLED will drive the next generation of AR optics by offering very high pixel densities and low latency. Integration with free-form optics and waveguides will be key systems challenges.

Improved Blue Emitters and TADF

Advances in TADF and other novel emitters target longer blue lifetime, closing the historical gap that causes color shift and reduced lifetime in OLED displays.

Conclusion — Choosing an OLED Display for Your Product

OLED displays provide industry-leading contrast, color and design flexibility. For product teams, success with OLED depends on a systems approach: UI/UX design that avoids static high-brightness content, firmware compensation for aging, thermal and mechanical design for longevity, and rigorous procurement/testing processes. When these practices are in place, OLED delivers superior visual experiences across consumer electronics, automotive, industrial and AR/VR markets.

Contact us for OLED module consultation →

FAQ — Common Questions About OLED Displays

What is an OLED display and how does it differ from LCD?

OLEDs use organic emitters per pixel (self-emissive), while LCDs require a backlight. This difference gives OLEDs true blacks, higher contrast, thinner panels and flexible form factors, at the cost of moisture sensitivity and potential burn-in under static high-contrast content.

How can I reduce the risk of burn-in on an OLED display?

Use dark UI themes, reduce maximum brightness, avoid static high-contrast elements, enable auto-dimming/screensavers, and ensure firmware compensation like pixel shifting and wear-equalization are present.

Which OLED type should I choose for a smartphone vs an AR headset?

Smartphones typically use AMOLED with LTPS/LTPO backplanes for high PPI and variable refresh. AR headsets benefit from microOLED for extremely high pixel density and low latency. Choose based on required PPI, latency, and power budget.

Leave a comment

Este site está protegido pela Política de privacidade da hCaptcha e da hCaptcha e aplicam-se os Termos de serviço das mesmas.