- 1️⃣ Introduction

- 2️⃣ What Does OLED Mean?

- 3️⃣ What Does OLED Stand For?

- 4️⃣ How Does OLED Work?

- 5️⃣ Types of OLED Displays

- 6️⃣ Advantages of OLED Displays

- 7️⃣ Disadvantages / Limitations

- 8️⃣ OLED vs IPS Displays

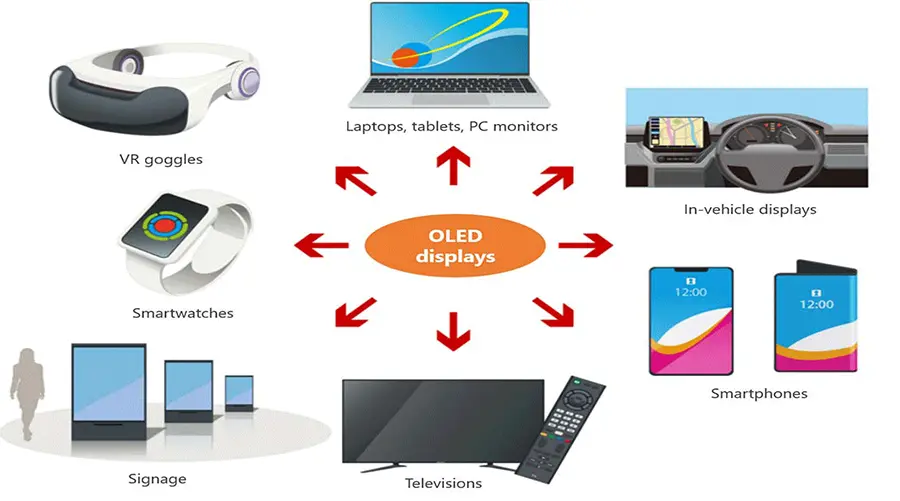

- 9️⃣ Applications of OLED Displays

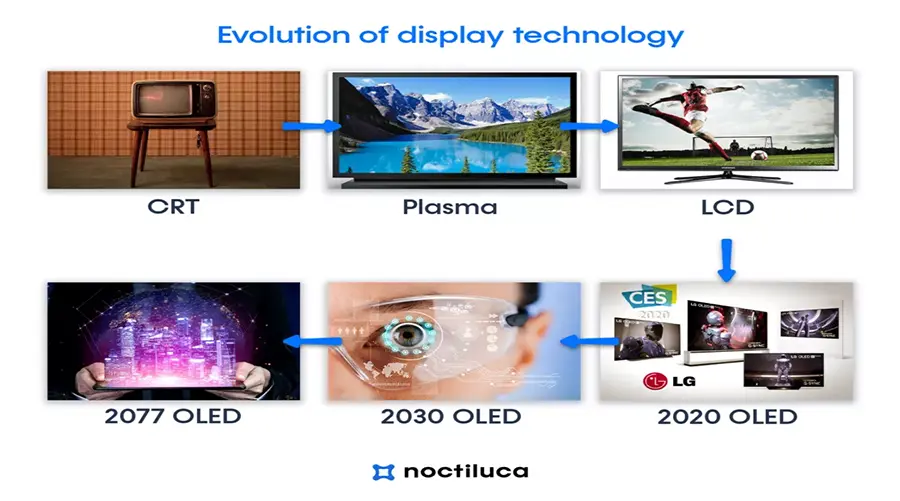

- 🔟 Future Trends & Industry Insights

- 1️⃣1️⃣ Frequently Asked Questions (FAQ)

- 1️⃣2️⃣ Conclusion

1️⃣ What Is an OLED Display and Why It Matters

OLED (Organic Light‑Emitting Diode) displays are self‑emissive—each pixel generates its own light. Unlike LCDs requiring a static backlight, OLED pixels glow through electroluminescence of organic compounds, enabling outstanding contrast and unprecedented form‑factor freedom.

Self‑Emissive vs Backlit LCD

LCDs block or pass uniform backlight through liquid crystals, while OLED pixels act as miniature light sources. The result is true‑black reproduction and faster response (<0.1 ms). Removing the backlight also reduces thickness to below 1 mm.

Key Advantages

- Infinite contrast and perfect blacks

- Flexible, curved, or transparent possibilities

- Wide viewing angle without color shift

- High response for immersive XR systems

Industry adoption accelerated from smartphones to TVs and automotive. Analysts forecast OLED shipment share >45 % in premium display sectors by 2030.

2️⃣ OLED Science: How Light Is Generated

OLED emission stems from carrier recombination inside organic thin films. Voltage injects electrons and holes from the cathode and anode, forming excitons that radiatively decay into visible light.

Pixel Structure & Exciton Recombination

Typical stack: transparent anode (ITO or graphene), hole transport, emissive, electron transport, and reflective cathode. Proper energy‑level alignment ensures radiative recombination efficiency up to 100 % in phosphorescent systems.

RGB vs WRGB

RGB uses discrete red, green, blue subpixels. WRGB (White + color‑filter) introduces an extra white subpixel to extend lifetime and brightness—commonly applied in large‑area OLED TVs.

Singlet vs Triplet Excitons

Fluorescent emitters radiate only singlet excitons (~25 %), while phosphorescent and TADF emitters harvest triplets thermally, approaching unity internal quantum yield. Advanced blue TADF reduces power yet extends operational stability.

3️⃣ Core OLED Materials & Structure

| Emitter | Description | Efficiency | Remarks |

|---|---|---|---|

| Fluorescent | π‑conjugated organics | ~25 % | Low‑cost short lifetime |

| Phosphorescent | Ir‑complex metal dopants | ~90 % | High efficiency, costly heavy metals |

| TADF | Thermal up‑conversion design | ≈100 % | Key enabler for sustainable blue emitter |

Transparent Electrodes

To support bending, brittle ITO is replaced with graphene, silver nanowire, or metal mesh structures offering comparable conductivity and high optical transmittance.

The Blue‑Emitter Bottleneck

High‑energy blue photons accelerate degradation; new phosphorescent blue complexes and TADF molecules have achieved >10 000 h lifetime under full‑white 100 nits—crucial for mass production.

4️⃣ OLED Manufacturing Technology

Display fabrication integrates sub‑micron precision with strict contamination control.

Vacuum Evaporation + Fine Metal Mask (FMM)

Dominant for high‑resolution smartphone panels. The shadow‑mask defines RGB areas but limits substrate area and drives capital expenditure.

Inkjet Printing

Additive inkjet printing reduces material loss >60 % and supports Generation 8 lines. As viscosity control advances, uniform film thickness ensures yields >85 % even for 65‑inch panels.

Backplane Technologies (LTPS / IGZO / Oxide TFT)

LTPS enables small‑pixel drive current; IGZO favors low power and large area. Emerging oxide TFT balances both, crucial for AR microdisplays.

Encapsulation

Moisture protection achieved via rigid glass or thin‑film encapsulation (TFE). Hybrid multilayer coatings attain WVTR < 0.001 g/m²/day for foldable designs.

5️⃣ OLED Display Performance Metrics

- Brightness > 1500 nits (peak)

- Contrast ∞ : 1 for absolute black

- Color Gamut > 95 % BT.2020 via QD‑enhancement

- Lifespan L50 > 30 000 h

- Response < 0.1 ms

Burn‑in Mitigation

Automatic pixel‑refresh, UI rotation, and temporal dithering algorithms reduce burn‑in risk > 90 %. Hardware solutions include dual‑stack OLEDs for current spreading.

Power vs APL

Power consumption ∝ Average Picture Level (APL). Dark themes save ≈ 40 % energy at 50 APL.

6️⃣ Types of OLED Displays

| Type | Application | Key Point |

|---|---|---|

| PMOLED | IoT modules | Low cost, low resolution |

| AMOLED | Phones & laptops | Mainstream high PPI |

| Flexible OLED | Wearables | PI substrate, fold radius <3 mm |

| Foldable / Rollable | Novel devices | Stress‑engineered thickness >200 k bends |

| Transparent | HUD / Retail display | Transmittance >70 % |

| MicroOLED | AR VR optics | 4000 PPI, silicon backplane |

7️⃣ OLED Application Fields

- Consumer Electronics — power efficiency & color accuracy demand

- Automotive — tandem stacks for high‑temp durability

- Medical Imaging — DICOM‑compliant grayscale and stability

- Wearables — always‑on with 0.3 W typical consumption

- AR/VR Microdisplays — high PPI & low latency

8️⃣ OLED vs Competing Technologies

| Metric | OLED | Mini‑LED LCD | MicroLED |

|---|---|---|---|

| Contrast | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Brightness | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Flexibility | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ |

| Cost Maturity | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ |

Mini‑LED offers extreme brightness for monitors; MicroLED promises lifetime and modular scalability. OLED presently balances maturity, flexibility, and optical performance for most high‑end needs.

9️⃣ Engineering Challenges & Solutions

- Brightness → Multi‑tandem OLED + micro lens array boosts extraction 50 %.

- Burn‑in → Algorithmic aging compensation + pixel shift firmware.

- Lifetime (blue) → TADF & phosphorescent blue development.

- Cost Reduction → Printing OLED and G8.7+ large substrate lines.

🔟 Future Outlook

QD‑OLED panels exceed 2000 nits while maintaining color volume; stretchable OLEDs shape wearable electronics; automotive clusters transition fully to OLED. MicroOLED drives AR optical modules with pixel density >5000 ppi.

Sustainability emerges as a core focus—solvent‑free printing reduces CO₂ by 40 %. OLED stands as the green, human‑centric visual platform for the next decade.

1️⃣1️⃣FAQ — Engineering & Procurement

How to prevent OLED burn‑in?

Use UI rotation, pixel‑refresh firmware, and burn‑in compensation maps. At panel level tandem structures spread current loads to extend uniform lifetime.

What lifetime can be expected for industrial panels?

Modern OLED exceeds 50 000 hours L50 at typical nits; environmental control maintains color stability throughout 10 years.

Is touch functionality compatible with OLED?

Yes — on‑cell or in‑cell touch integration is standard, using metal‑mesh transparent electrodes to retain flexibility.

How does OLED compare to MicroLED long‑term?

MicroLED targets higher brightness and hard wear, yet mass‑transfer costs remain high. OLED dominates for design freedom and shorter production cycle.

Leave a comment

Este site está protegido pela Política de privacidade da hCaptcha e da hCaptcha e aplicam-se os Termos de serviço das mesmas.