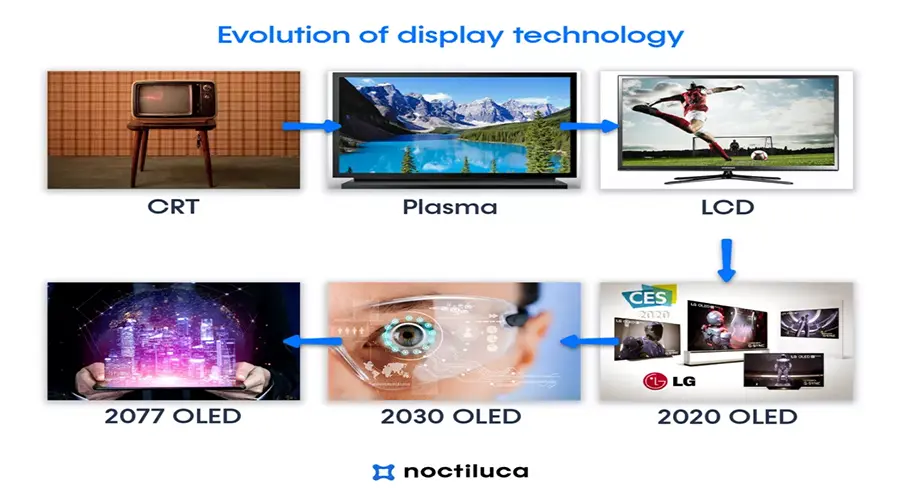

OLED Displays (Organic Light Emitting Diode) are self-emissive screens where each pixel lights independently. This enables ultra-thin modules, premium image quality, low-power dark UI performance, and flexible designs — making OLED ideal for next-gen industrial, wearable, automotive and retail devices.

TL;DR — Quick Engineering Summary

- Self-emitting pixels → no backlight → True black + extreme contrast

- Ultra-thin form factors → flexible, curved and transparent designs

- Fast response + wide viewing angles → ideal for motion UI and video

- Outdoor visibility depends on brightness + AR films

- Static UI may cause burn-in → needs UI/firmware prevention strategy

1️⃣ What is an OLED Display? (Principles & Types)

How OLED emits light

Each pixel contains organic semiconductor material. When voltage is applied, it emits light directly — resulting in true black and high contrast.

Main Types

- AMOLED — TFT active matrix, suited for high-res & larger displays

- PMOLED — simple passive matrix, for small icons & wearables

Form Factors

- Flexible & Curved OLED

- Foldable OLED

- Transparent OLED

2️⃣ Key Advantages & Engineering Considerations

Advantages

- True black + Millions:1 contrast (per-pixel OFF state)

- Ultra-light + ultra-thin (no backlight stack)

- Faster than LCD → ideal for animations & real-time UI

- Wide viewing angle, high color saturation (DCI-P3 95–100%)

Limitations

- Lower peak brightness vs MiniLED in direct sunlight

- Burn-in risk on static UI → needs compensation algorithms

- Higher cost on large / special shapes (transparent, curved)

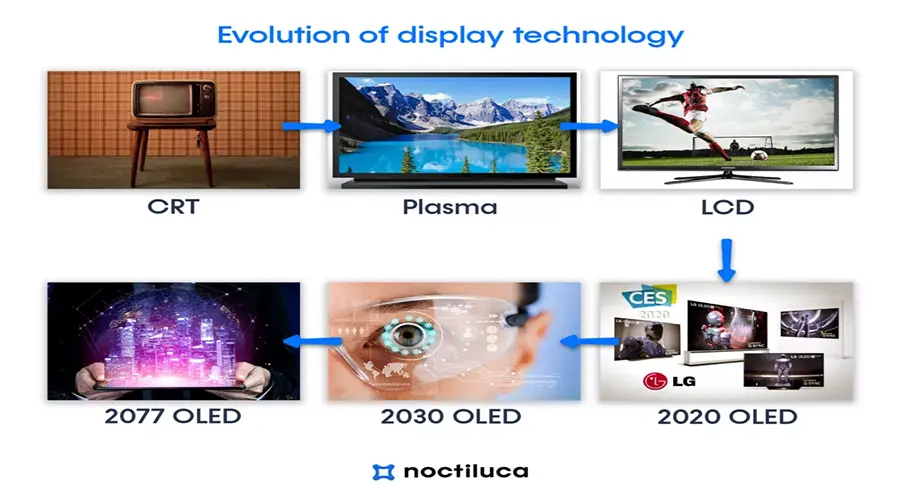

3️⃣ OLED Display Applications

- Industrial HMI — better UI readability in compact devices

- Automotive — curved dashboards, wide-temp stability

- Wearables — low power dark UI, comfortable form factors

- Medical & Instruments — high contrast data visualization

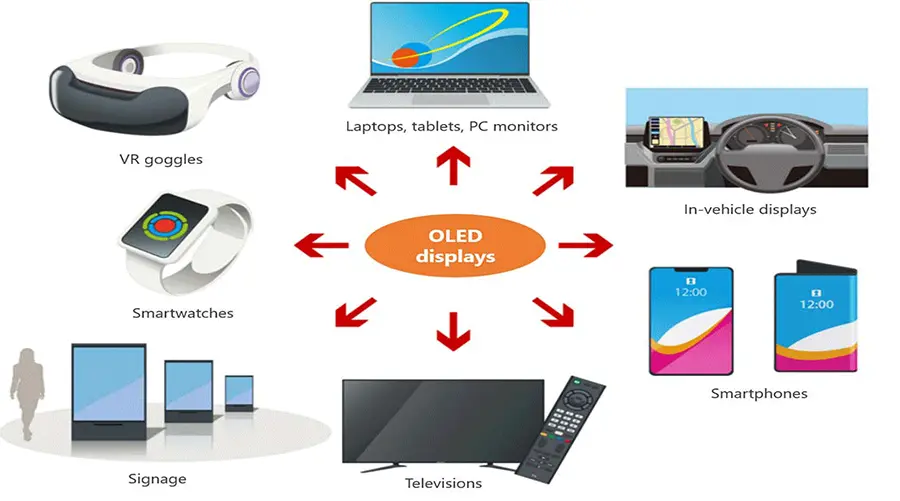

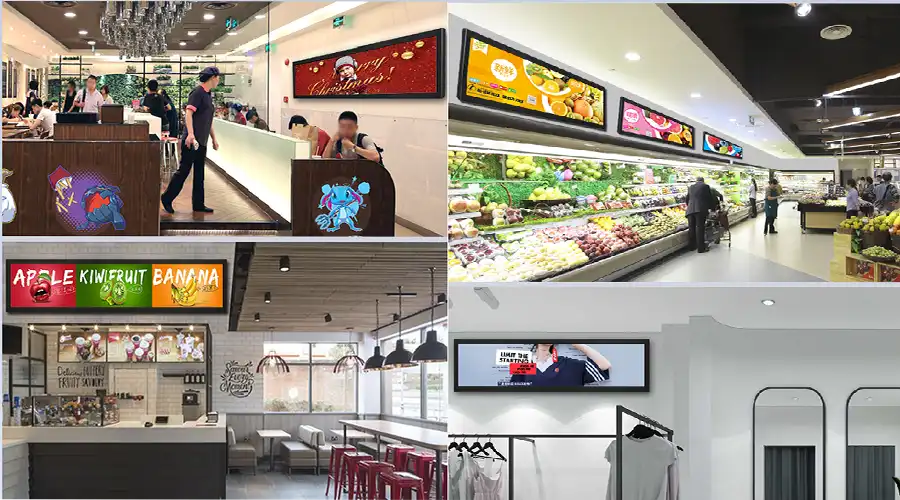

- Smart Retail & Transparent Signage

| Industry | OLED Benefit | Key Requirement |

|---|---|---|

| Industrial HMI | Readability, Thin Design | -20~70°C, Impact-resistant cover |

| Automotive | Curved cockpit display | Wide-temp -40~85°C |

| Wearables | Ultra-low power | Small size, SPI/I2C |

4️⃣ OLED vs LCD / MiniLED / MicroLED

| Feature | OLED | MiniLED LCD | MicroLED |

|---|---|---|---|

| Black / Contrast | ★★★★★ | ★★★★☆ | ★★★★★ |

| Thickness | Ultra-thin | Thicker | Thin |

| Peak Brightness | Medium | High | Very High |

| Static UI Risk | Possible burn-in | No | No |

5️⃣ Key Specs & B2B Selection Guide

Must-check Engineering Specs

- Size & Resolution

- Brightness & Polarizer / AR coating

- Refresh & Response time

- Interface: MIPI / eDP / LVDS / SPI

- Power consumption (UI related)

- Operating temp — Industrial vs Automotive grade

- Touch integration: On-Cell / OGS

✅ Conclusion

OLED Display is one of the strongest display solutions for products requiring premium UX, real-time motion, thin design, and energy efficiency. For outdoor high-brightness or ultra-long lifetime products, hybrid solutions may be evaluated.

Send us your requirements — size, brightness, interface, and environmental demands — and we will provide: Datasheet + Samples + Mass-production plan.

📩 Contact BROWNOPTO for OLED Solutions →

FAQ: Common B2B Questions

댓글 남기기

이 사이트는 hCaptcha에 의해 보호되며, hCaptcha의 개인 정보 보호 정책 과 서비스 약관 이 적용됩니다.