Industrial applications demand displays that are not only visually excellent but also robust, reliable and easy to integrate. Industrial OLED display modules combine the emissive advantages of OLED technology—true blacks, high contrast and wide viewing angles—with engineering features required in industrial environments: extended temperature ranges, rugged encapsulation, long MTBF, and flexible electrical interfaces. This guide covers core principles, key specifications, integration tips, and a decision checklist for engineers and procurement teams.

Table of Contents

- What is an industrial OLED display module?

- Construction & design considerations

- Critical specifications to evaluate

- Electrical & mechanical interfaces

- Environmental & reliability requirements

- Integration best practices

- OLED vs other display technologies in industry

- Typical industrial use cases

- Quick spec comparison table

- FAQ

- Conclusion & next steps

What is an industrial OLED display module?

An industrial OLED display module is a fully packaged OLED panel that includes the OLED emission stack, driver electronics (often a local controller), mechanical housing, front cover (glass or polycarbonate), and the electrical connectors required for integration. Unlike consumer modules, industrial variants are engineered for:

- Extended operating temperature ranges (e.g., −30°C to +85°C)

- Higher ingress protection and mechanical robustness

- Longer lifecycle with monitored drift compensation

- Optional features such as optical bonding, sunlight-readable coatings, and MIL-STD vibration qualifications

Construction & design considerations

Panel & backplane

Industrial modules typically use AMOLED (active-matrix OLED) panels for high resolution and reliable drive. Backplane choices (LTPS, LTPO, or IGZO) affect refresh control, leakage and suitability for low-frequency always-on displays. For industrial HMI with static indicators, low-leakage oxide backplanes can reduce pixel drift and improve long-term uniformity.

Encapsulation & cover

OLED organics are sensitive to moisture and oxygen. Industrial modules use robust encapsulation: glass + edge seal, or thin-film encapsulation (TFE) on flexible panels. Cover options include AR-coated glass, chemically strengthened glass (e.g., Gorilla®), or optically bonded laminated glass to eliminate air gaps and improve durability.

Thermal management

OLED lifetime and color stability depend on temperature. Industrial modules often include thermal paths—metal backplates, thermal pads, or dedicated heat spreaders—to maintain panel temperature within the specified range under continuous operation.

Critical specifications to evaluate

When specifying an industrial OLED module, focus on measurable parameters rather than marketing phrases. Key specs include:

- Diagonal & active area — exact mechanical dimensions and usable aperture.

- Resolution & pixel pitch — PPI for text clarity and UI requirements.

- Peak & sustained luminance — nits for highlight vs full-screen brightness.

- Contrast ratio — typically very high for OLED; specify at given ambient conditions.

- Color gamut & ΔE — factory calibration and target white point (e.g., D65).

- Viewing angle — off-axis performance per IEC standard.

- Operating/storage temperature — specify both extremes and thermal derating rules.

- MTBF / luminance lifetime (T80/T90) — measured under defined APL and nits.

- Ingress protection / mechanical specs — IP rating, shock/vibration standards.

- Interfaces — MIPI DSI, LVDS, eDP, SPI, or parallel RGB and power requirements.

Electrical & mechanical interfaces

Common electrical interfaces

Industrial modules support a range of interfaces depending on the controller board:

- MIPI DSI / eDP — typical for high-resolution AMOLED panels driven by modern SoCs.

- LVDS / Parallel RGB — legacy industrial controllers and FPGA boards.

- SPI / UART — for simple monochrome/low-res OLED modules or control channels.

- Power rails — careful attention to VGH/VGL driver rails, boost converters, and inrush currents.

Mounting & mechanical considerations

Provide clear mechanical drawings (3D STEP preferred) for bezel cutout, mounting hole torque limits, and connector orientation. Consider front gasket seals and EMI grounding—industrial environments often require conductive gasketing and controlled grounding paths.

Environmental & reliability requirements

Temperature & humidity

Specify operation at defined temperature and humidity ranges and provide thermal cycling test requirements. For outdoor or vehicle use, require extended ranges (e.g., −40°C to +85°C) and UV-resistant coatings for front glass.

Shock, vibration & lifecycle

Include MIL-STD-810 or IEC 60068 test profiles when necessary. Ask suppliers for accelerated lifetime data (T80 at specified APL and ambient) and for evidence of burn-in mitigation strategies (pixel shifting, logo dimming, or compensation LUTs).

Integration best practices

Design for longevity

Industrial UIs often display static logos and status bars — known burn-in triggers. Use these recommendations:

- Design UIs with dark backgrounds for OLED longevity where possible.

- Implement periodic content rest cycles and pixel shift to distribute wear.

- Use duty-cycle limits for high-brightness content and specify automatic dimming thresholds.

Calibration & factory tuning

Request per-panel factory calibration data (gamma curves, white point, ΔE measurements). For multi-panel systems, ask for matching reports to ensure consistent color across units and batches.

EMC & grounding

Industrial equipment must meet EMC/EMI standards. Ensure the module provides recommended grounding pads, shield cans for driver boards, and filtering for high-frequency switching elements (buck/boost converters).

OLED vs other display technologies in industry

Compare objectively:

| Metric | OLED (industrial) | Transmissive LCD | MicroLED |

|---|---|---|---|

| Contrast | Excellent (true black) | Moderate (backlight bleed) | Excellent |

| Peak brightness | Good (phone/TV level), limited full-screen | High (with bright backlight) | Very high |

| Power (dark UI) | Low | Higher (constant backlight) | Depends on APL, efficient at high nits |

| Burn-in risk | Present — needs mitigation | Low | Minimal |

| Durability (temperature) | Good, with engineering | Good | Excellent |

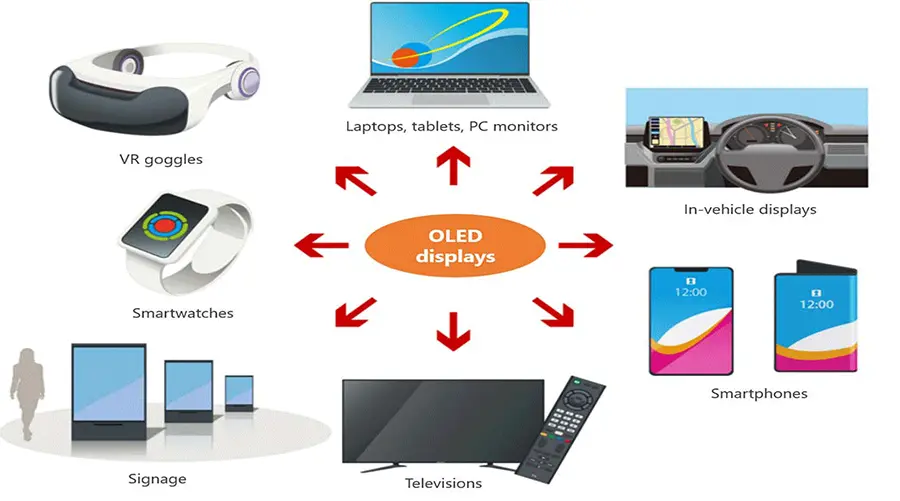

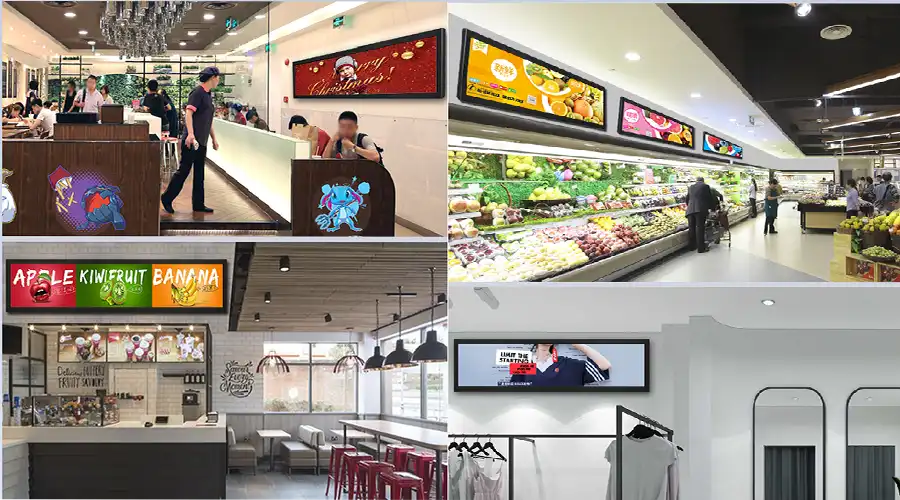

Typical industrial use cases

Human-Machine Interfaces (HMI)

Control panels in automation, factory machinery touchscreens, and medical device displays benefit from OLED’s superior contrast and viewing angle. For HMI with mixed dynamic content, AMOLED with LTPO or similar backplanes provides flexible refresh and lower power.

Instrumentation & analytical equipment

Lab instruments and measurement equipment often require precise readouts with high contrast and color accuracy — OLED modules with factory calibration are excellent here.

Vehicle & rail displays

Instrument clusters and passenger information displays require high brightness, temperature tolerance and long life. Automotive-grade OLED modules with advanced encapsulation or MicroLED alternatives can be appropriate choices.

Quick specification checklist (for RFQ)

| Item | Requirement / Example |

|---|---|

| Model / Part | XX-YY-IPS-OLED-07-800 (vendor SKU) |

| Active area (mm) | 120.0 × 67.5 |

| Resolution | 1280 × 720 (PPI: 217) |

| Brightness | Peak 800 nits (spot), Sustained 300 nits full-field |

| Contrast | >100,000:1 (typical) |

| Interface | MIPI DSI (4-lane) + I2C touch |

| Operating Temp | −30°C to +85°C (storage −40°C to +90°C) |

| Ingress Protection | IP54 (front), gasketed housing available |

| Calibration | Factory ΔE < 3; ICC profile supplied |

FAQ — Industrial OLED Display Module

Q: Are industrial OLED modules suitable for 24/7 operation?

A: Yes — many industrial OLED modules are engineered for continuous operation. Confirm vendor T80/T90 lifetime at your target APL and ask for recommended operating brightness and duty cycles.

Q: How to mitigate OLED burn-in for static HMIs?

A: Use dark-themed UI, pixel-shift, periodic full-screen refreshes, and rotate static icons. Specify vendor compensation algorithms and request evidence of burn-in testing.

Q: Can industrial OLEDs work outdoors in sunlight?

A: Some modules include high-brightness options (1000+ nits) and anti-reflective coatings for outdoor readability. Assess APL, thermal derating, and cover glass selection for outdoor deployment.

Q: What certifications should I request?

A: Ask for IEC/EN temperature/humidity test reports, MIL-STD vibration/shock (if required), RoHS, REACH, and automotive ISO/TS qualifications for in-vehicle use.

Q: How do I request samples and volume pricing?

A: Provide exact RFQ specs (see checklist table), intended duty cycle, expected annual quantity, and any environmental test requirements. Request both sample and production yield data.

Conclusion & next steps

Industrial OLED display modules offer unmatched contrast and user experience for HMIs, instrumentation and specialized displays, but they require careful specification and integration planning—especially around thermal design, burn-in mitigation and environmental protection. Use the RFQ checklist above, require per-panel calibration reports, and pilot test modules under your actual duty cycles before scaling to production.

Share your target size, required brightness, expected duty cycle, operating temperature range and annual quantity — we can propose suitable industrial OLED module options and provide a supplier comparison matrix.

댓글 남기기

이 사이트는 hCaptcha에 의해 보호되며, hCaptcha의 개인 정보 보호 정책 과 서비스 약관 이 적용됩니다.