This in‑depth guide explains the real differences between OLED (Organic Light‑Emitting Diode) and AMOLED (Active‑Matrix OLED). Drawing on materials science, device physics, and manufacturing practice, we compare structure, drive schemes, performance metrics (brightness, contrast, color, response, power), reliability (lifetime, burn‑in mitigation), and cost. You’ll also get a clear selection framework by application (smartphones, wearables, automotive, industrial HMI, medical, and XR).

Table of Contents

Definitions: OLED vs AMOLED

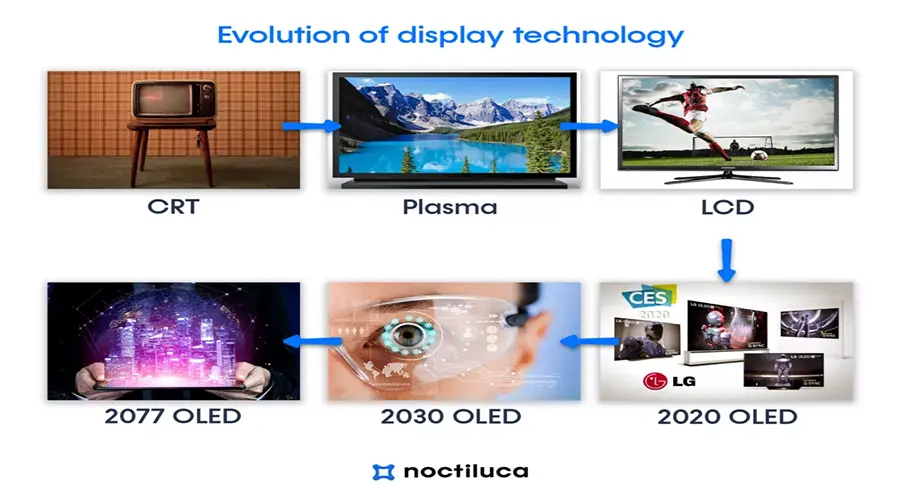

OLED is an emissive display technology: each pixel is a stack of organic layers that emit light when an electric current flows. Because there’s no backlight, OLED panels achieve near‑infinite contrast and superb black levels while enabling ultra‑thin and flexible form factors. In industry naming, “OLED” can refer to any organic LED panel—either passive‑matrix (PMOLED) or active‑matrix.

AMOLED specifically means Active‑Matrix OLED. An TFT backplane (typically LTPS or LTPO on glass; polyimide on flexible) drives each sub‑pixel through a dedicated pixel circuit (e.g., 2T1C/3T1C). This active addressing enables high resolution, high refresh rates, and fine grayscale control. In consumer electronics, when people say “OLED phone”, they almost always mean AMOLED.

How They Work: Device Structure & Drive

Emissive Stack & Sub‑Pixel

A typical emissive stack includes anode, hole‑injection/transport layers (HIL/HTL), emissive layer(s) (EML), electron transport layers (ETL), and cathode. Materials may be fluorescent (blue), phosphorescent (red/green), or TADF variants. The sub‑pixel comprises red, green, and blue emitters (RGB stripe) or a PenTile‑like arrangement to balance lifetime and resolution perception.

Passive‑Matrix (PMOLED) vs Active‑Matrix (AMOLED)

PMOLED addresses pixels by row/column scanning without per‑pixel capacitive storage; it suits small, simple displays (icons, short text) at modest brightness and resolution. AMOLED integrates TFT pixel circuits with a storage capacitor, holding the pixel level between refreshes. This supports high PPI, video‑rate operation, PWM/analog dimming, and wide grayscale depth.

Backplane Technologies (LTPS, LTPO, Oxide)

Most AMOLED phones use LTPS TFT for high carrier mobility and tight pixel control. LTPO combines LTPS + Oxide for low leakage and variable refresh down to 1–10 Hz, enabling always‑on displays with reduced power. Oxide TFTs (IGZO) are common in large panels for better uniformity and cost trade‑offs.

Driving & Dimming

Pixel circuits can be driven by analog current (for linear grayscale) and/or PWM (for extended dynamic range and low‑level stability). Compensation schemes (e.g., sensing Vth shifts in the TFT) maintain uniform luminance over aging and temperature.

Performance Comparison

Brightness & HDR

Peak luminance depends on emitter efficiency, aperture ratio, and thermal management. Modern AMOLED phone panels routinely exceed 1000–2000 nits peak in HDR highlights, with sustained full‑screen brightness constrained by thermal and lifetime budgets. PMOLEDs are typically hundreds of nits and not suitable for HDR video. For outdoor readability and automotive sunlit conditions, AMOLED’s active drive and compensation achieve higher usable brightness with controlled ABL (automatic brightness limiter) behavior.

Color Gamut & Accuracy

Both OLED and AMOLED can cover wide color gamuts (DCI‑P3 and beyond). AMOLED implementations often include factory calibration (2.2/2.4 gamma options, white‑point modes) and per‑panel LUTs to reach ΔE<2 accuracy. PenTile layouts may reduce raw sub‑pixel count but leverage human visual sensitivity to maintain perceived resolution while improving blue lifetime.

Response Time & Motion

OLED emissive materials switch in microseconds, essentially eliminating traditional LCD sample‑and‑hold blur. AMOLED’s active matrix enables 90/120/144 Hz refresh with low MPRT via black‑frame insertion or high‑frequency PWM dimming. That’s why AMOLED dominates gaming phones and XR microdisplays.

Power Consumption Models

Power roughly scales with the area‑weighted luminance of lit sub‑pixels. Dark UI themes save power because black pixels emit no light. AMOLED backplanes (especially LTPO) lower baseline consumption by reducing refresh in static scenes (AoD, notifications). Conversely, bright, full‑screen white UIs (e‑mail, documents) can draw more power than LCD, particularly at high APL (average picture level).

Viewing Angle & Uniformity

Emissive pixels maintain contrast at oblique angles better than LCDs. However, color shift from microcavity effects can appear at very wide angles. AMOLED panels employ optical compensation films and calibration to reduce tint and Mura (luminance non‑uniformity).

.

.Reliability & Lifetime

OLED emissive materials age with cumulative current; blue sub‑pixels typically decay fastest. Key reliability metrics include T95/T80 at specified nits and APL, image retention, and burn‑in risk. AMOLED manufacturers mitigate with sub‑pixel design (larger blue), pixel‑shift, logo dimming, Aging compensation, and content‑aware UI strategies. Proper thermal design and reduced full‑screen white usage extend lifetime in signage/HMI.

Environmental Robustness

Moisture/oxygen ingress harms organics, so encapsulation is critical: TFE (thin‑film encapsulation) on flexible panels, glass encapsulation on rigid. Automotive/industrial AMOLED panels specify wide operating ranges (e.g., −30 ~ +85 °C), anti‑reflective cover glass, and high‑T NI adhesives to endure vibration and UV.

Manufacturing, Pixel Layouts & Cost

AMOLED production involves backplane fabrication (LTPS/LTPO/IGZO), organic stack deposition (often via FMM evaporation for RGB, or color‑filter/wRGB architectures on TVs), encapsulation, module lamination, and touch integration. Yield losses come from particle defects, FMM sagging, and mura, which raise cost—particularly on large/curved substrates. PMOLED is simpler/cheaper but limited in resolution/size.

Pixel Layout Choices

- RGB Stripe: Highest true sub‑pixel count; used where fine text rendering matters.

- PenTile (RG‑BG): Fewer blue sub‑pixels per area to improve lifetime; common in phones.

- wRGB / Color‑Filter on OLED: Used in large TVs to circumvent FMM limits; adds CF losses but boosts manufacturability.

Cost Drivers

- Backplane type (LTPO adds masks/complexity but saves power in AoD/VR).

- Flexible vs rigid substrate (polyimide + TFE increases cost yet enables curved/foldable designs).

- PPI and diagonal size (higher PPI and larger size lower yield at fixed generation lines).

- Touch integration (on‑cell/under‑panel optics, cover glass, coatings, anti‑reflective stacks).

Application‑Driven Selection Guide

Smartphones

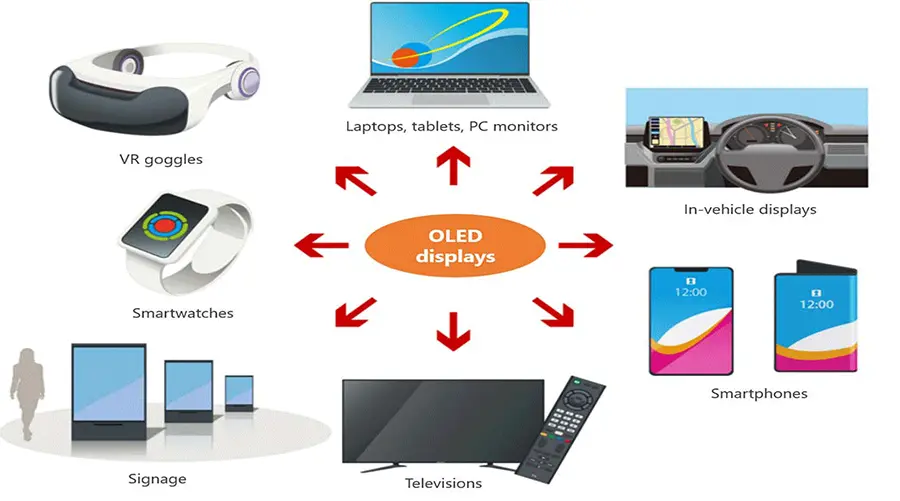

Choose AMOLED (LTPO) for premium models: 1–120/144 Hz variable refresh, high HDR peaks, tight factory calibration, and excellent AOD efficiency. Mid‑tier devices may use LTPS AMOLED or rigid OLED for cost balance.

Wearables

Small, round, or custom shapes benefit from OLED/AMOLED with TFE on flexible substrates. Prioritize low baseline power, high contrast outdoors, and robust cover glass. PMOLED can work for minimalist fitness bands; for richer UI, AMOLED wins.

Automotive

For instrument clusters and center stacks, select automotive‑grade AMOLED with wide temp, anti‑reflective optics, and burn‑in mitigation (logo dimming, content rotation). Rigid OLED can serve secondary displays; HUDs may favor micro‑OLED or other tech.

Industrial HMI & Signage

If UI is predominantly dark and information‑dense, AMOLED delivers superb contrast and responsiveness. For static, bright full‑white screens, evaluate power and burn‑in; consider UI rest periods and pixel shifting. When extreme longevity at static content is critical, weigh AMOLED vs transflective LCD or microLED.

Medical & Scientific

Demand tight color accuracy and uniformity. Use AMOLED panels with calibrated D65 white point, low Mura specs, and verified ΔE performance. For surgical environments, assess maximum sustained luminance and cleanability of cover glass/coatings.

Side‑by‑Side Comparison Table

| Category | OLED (General / PMOLED) | AMOLED (Active‑Matrix) |

|---|---|---|

| Drive Scheme | Passive row/column scan; no per‑pixel storage | TFT pixel circuits with storage capacitor; precise per‑pixel control |

| Resolution / PPI | Low‑to‑mid; suited to small icons/text UIs | High PPI; supports FHD/QHD/4K and beyond |

| Refresh / Motion | Basic animation; video limited | 90–144 Hz+ with low blur; gaming/XR capable |

| Brightness / HDR | Hundreds of nits; HDR uncommon | 1000–2000 nits peaks common; HDR10/HLG capable |

| Power | Efficient for dark UIs; limited controls | LTPO/compensation improve efficiency; variable refresh |

| Uniformity / Calibration | Basic; more variance across panel | Factory calibrated; compensation reduces Mura/tint |

| Typical Uses | Wearable bands, simple indicators | Phones, watches, laptops, automotive, VR/AR |

| Cost | Lower for small/simple modules | Higher; driven by backplane, yield, flexibility |

FAQ

Is AMOLED always better than OLED?

For high‑resolution, video‑rate, or gaming‑class devices, AMOLED is better due to its active‑matrix control, higher refresh, and refined calibration. For tiny, simple displays, PMOLED/OLED can be more cost‑effective and power‑efficient.

Which lasts longer: OLED or AMOLED?

Lifetime is governed by materials and drive conditions rather than the name. Modern AMOLED panels integrate compensation, pixel shifting, and content management to mitigate burn‑in and extend usable life compared with basic PMOLED modules.

Why do some AMOLED phones show PenTile sub‑pixels?

PenTile reduces blue sub‑pixel density to extend lifetime while keeping perceived resolution high. Calibration and rendering algorithms preserve text sharpness in practice.

Does dark mode really save power on AMOLED?

Yes. Black pixels emit no light, so area‑weighted luminance drops. Savings vary with APL and UI; LTPO further helps by lowering refresh for static scenes (AoD/lock screen).

Can I use AMOLED for bright, static signage?

It’s possible, but plan for content rotation, logo dimming, and rest intervals. For always‑white static UIs, consider UI redesign (dark themes) or evaluate alternative technologies.

Conclusion & Next Steps

In short, AMOLED is the active‑matrix realization of OLED that unlocks high resolution, high refresh, excellent HDR, and calibrated color for modern devices. OLED/PMOLED remains valuable for compact, low‑power modules. Choose based on your UI luminance profile, size/PPI needs, thermal envelope, and lifetime targets.

- Share target size/PPI, brightness (typical/peak), and operating temperature.

- Describe UI (dark vs bright), refresh requirement, and expected duty cycle.

- We’ll propose suitable AMOLED or OLED modules and provide optical/electrical specs.

댓글 남기기

이 사이트는 hCaptcha에 의해 보호되며, hCaptcha의 개인 정보 보호 정책 과 서비스 약관 이 적용됩니다.